ROTOMATIC PLUS

×

ROTOMATIC PLUS

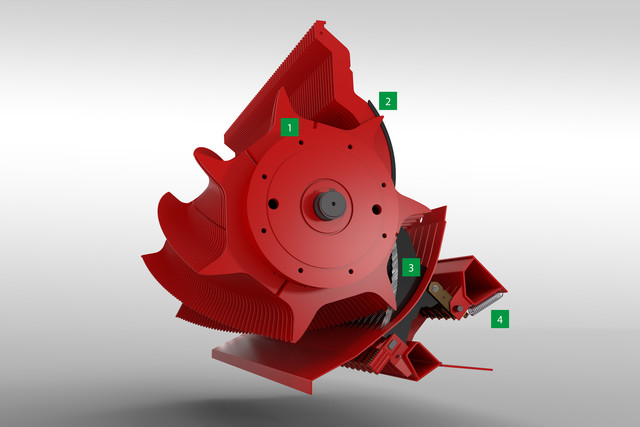

1- ROTOMATIC PLUS

2 - Scrapers

3- Short chop system

4 - Knife protection system

ROTOMATIC PLUS

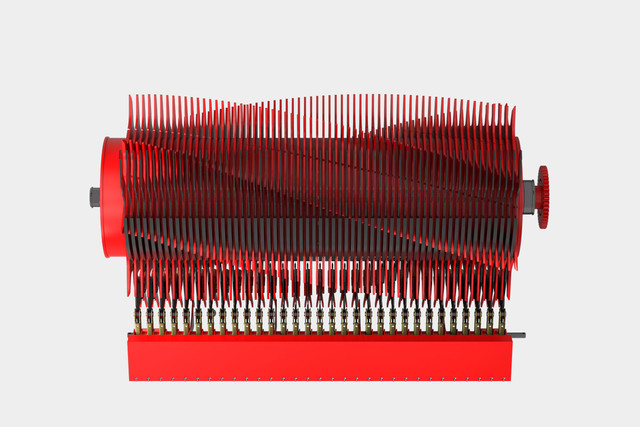

The loading rotor with a diameter of 750 mm achieves a high throughput during chopping, conveying and compacting. The 7 mm thick conveyor tines are made of durostat hardened and tempered boron steel and feed the crop perfectly into the chopping system.

ROTOMATIC PLUS

Short chop system

With a theoretical chopped length of 45 mm

Knife protection system

The reliable knife protection system protects the loader wagon from foreign objects, avoids downtimes and promotes a consistent chop length for the highest possible forage quality at high outputs.

Scraper beam

The large scraper area inside the loading chamber ensures excellent conservation for all types of forage. This makes the FARO highly suitable for mixed farming operations.

ROTOMATIC PLUS

ROTOMATIC PLUS is the heart of the FARO range. Rugged and powerful, the rotor delivers high output chopping and compression.

ROTOMATIC PLUS represents smooth, efficient chopping of the crop and perfect transfer from the pick-up.

Loading rotor with seven rows of double tines arranged in a helix, diameter: 750 mm

The loading rotor is mounted on self-aligning ball bearings at both ends

The bearings between the rotor and the rotor drive frame protect the bearings and drive chain.

Optimised tine geometry

The double conveyor tines made from hardened durostat 500 fine-grained steel are 7 mm thick and ensure maximum performance, even with short, wet forage. The optimised tine shape and large scraper surface ensure the best possible compression in the loading chamber.

The tine rings are hooked into the central drum and welded around the circumference for exact positioning.

The scrapers have an 12 mm wide rear face and are individually mounted and bolted. They ensure highest possible compression, depending on how the automatic loading system is set.