A controlled floating pick-up

×A controlled pick-up for clean forage

FARO 4010 D COMBILINE

The sealed twin-race roller bearings fitted to the cam rollers are designed to withstand high stresses. With the sweeping action of the tines on the pick-up, it conserves the sward, lowers the level of dirt ingress and prevents unnecessary wear to the tines.

The pick-up with perfect ground tracking for the lowest possible crude ash content makes the loader wagon particularly suitable for harvesting forage.

Clean forage

The interaction of the controlled pick-up with the floating pick-up suspension and the low pressure on the ground results in the cleanest possible collection of the crop. This ensures the contamination level is within the limit values of 80-100 g / kg of dry matter.

Perfect forage flow

An optional wind guard with swath roller and guide plates ensure perfect forage flow with every type of crop, even at higher loading speeds.

Tidy transfer

The fully active tine leg length on the controlled pick-up transfers the flow of crop smoothly to the rotor, even in difficult harvest conditions.

Best chopping quality

Instead of dragging the forage through, the system promotes the best possible chopping quality.

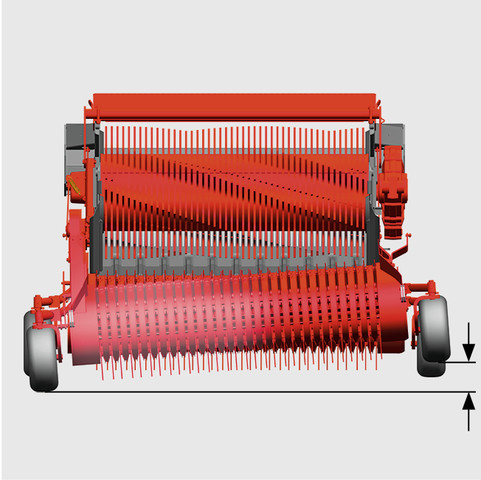

Pendulum radius

150 mm travel path

With a vertical travel of 150 mm on the pick-up, PÖTTINGER ensures perfect ground tracking and exact contouring.

Floating pick-up

A controlled floating pick-up

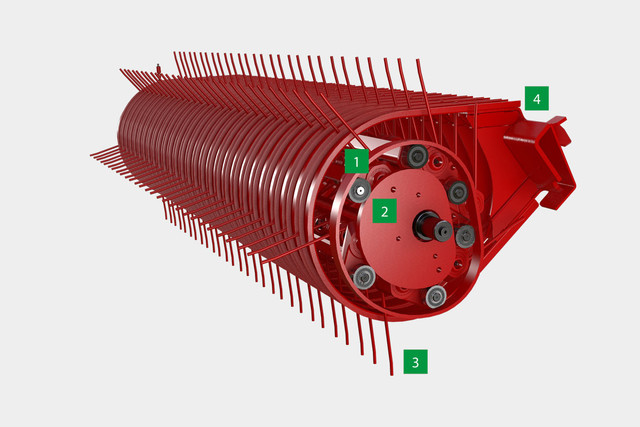

1 - Curved track

2 - Solid core

3 - Pick-up tines

4 - Scrapers

A controlled floating pick-up

Maximum intake thanks to the 6-row PÖTTINGER floating pick-up.

Cam track at both ends

The shape of the cam track ensures optimum movement of the tines. This ensures the trailing tines pick up the forage at the correct angle. They convey the crop gently upwards, actively transfer the crop to the rotor at an adjusted speed and at the defined transfer point. The tine dips down at a right angle to prevent the forage from being drawn in.

The cam tracks with solid cores at either end of the pick-up guarantee a long service life and maximum efficiency

Pick-up tines

The tines are slightly trailing to sweep in a controlled arc and adapt ideally to contours. Clean forage is guaranteed as a result. The fully active tine length up to the withdrawal point ensures the forage is transferred to the rotor perfectly. Thanks to the reduced speed of the rotor, the forage is not dragged but fed actively into the rotor. Maximum conveying performance at high driving speeds. Reliable high intake performance, even in difficult harvesting conditions.

Full freedom of movement

Two support arms and a special universal joint ensure the pick-up has complete freedom of movement.

The universal joint ensures smooth guidance of the pick-up so that it can collect crop cleanly even on bumpy terrain.

FARO 4010 L COMBILINE

Maximum intake

The PÖTTINGER pick-up guarantees maximum feed rate. The transfer zone from the pick-up tines to the rotor has been optimised and adapted for high throughput capacity. The PÖTTINGER floating pick-up with six rows of tines delivers impressive performance – even at high driving speeds and in difficult harvest conditions – for reliable, high intake performance.

Perfect ground tracking

Two support arms ensure the pick-up has complete freedom of movement. A spring alleviates the pick-up weight so less pressure is exerted on the ground.

Height adjustable jockey wheels contact the ground on precisely the same line as the tines to ensure perfect ground tracking and cornering.

Perfect ground tracking for a low crude ash content

Ground hugging

The two support arms on the pick-up as well as the height adjustable trailing jockey wheels ensure perfect ground tracking. In addition, weight alleviation springs are provided as standard to ensure a low ground pressure of around 100 kg.

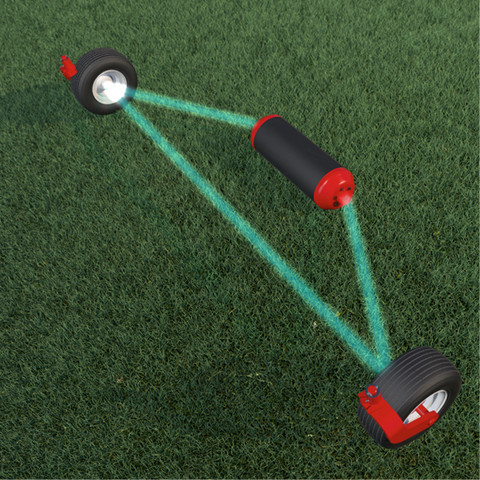

Additional tracking roller

Additional tracking roller for the highest forage quality

The optional additional tracking roller prevents the pick-up sinking into tractor wheel marks. It is located on the centreline behind the pick-up and covers a wide area of ground thanks to its generous dimensions. Together with the two jockey wheels, the additional tracking roller forms a support triangle for perfect ground tracking.

This considerably reduces the tines scraping the soil so contamination of the forage is avoided.

Parallel linkage

Unique parallelogram guidance

The parallelogram linkage on the pick-up leads to significantly better ground tracking.

You get clean forage even in difficult conditions. The freedom of movement of the pick-up is still 100%.

The working height is adjusted independently of the front jockey wheels.

Support triangle

Support triangle

The two jockey wheels and the optional additional tracking roller form a stable support triangle. This significantly increases the area of ground contact and ensures perfect crop collection even in bumpy terrain.