Superstructure

×

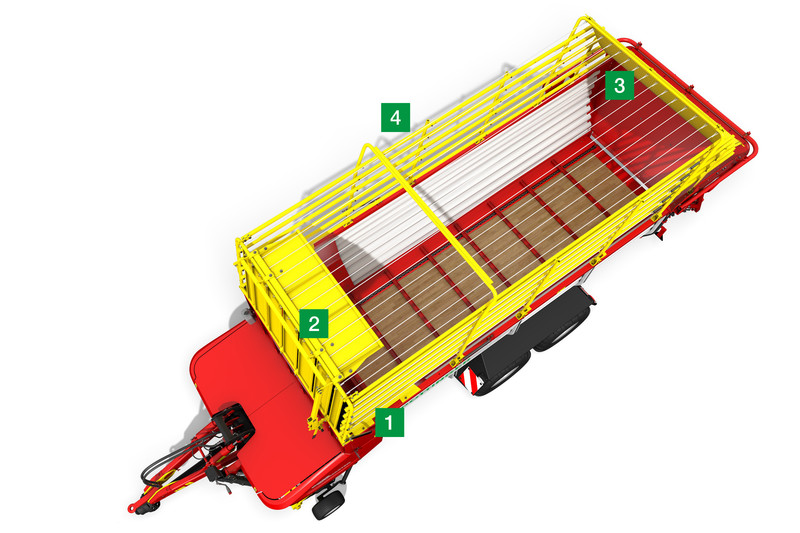

Superstructure - flexible and light

The structure of the BOSS 3000 can be matched exactly to your needs. The slim waistline makes it possible to lower the loading chamber between the wheels and therefore have a low centre of gravity, which is ideal on steep ground. The dry forage extension is also lightweight and keeps the centre of gravity down. With the optional crop retention nets, it works like an all-steel superstructure, but with less weight and can still be folded down.

1 Hydraulic folding

For low clearances

2 Automatic loading

Increases operator convenience

3 Roof ropes with rear tarpaulin

Stops the crop from spilling over the top or to the rear

4 Dry crop extension

Lightweight and durable

High and low profile loader wagons

The BOSS 3000 is available in two versions, as a high-profile or low-profile loader wagon. As a low-profile loader wagon (LP), it is 190 mm lower than the standard high-profile version with an overall height of 3.26 mm. This lowers the centre of gravity to such an extent that these loader wagons are also ideally suited for working on Alpine foothills.

The loading chambers are available in sizes of 18.7 / 21.3 / 23.9 and 26.5 m³.

Scraper floor

The scraper floor has two strong round link chains with bolted-on scraper floor slats. It is hydraulically driven which makes it easy to adjust the speed. Depending on the version, this can be done easily from the control terminal. As standard, the scraper floor can also be operated from the rear of the wagon.

The wooden floor is pressure impregnated to increase durability.

Dry crop extension

BOSS loader wagons have a dry forage extension as standard. This can be folded down hydraulically, reducing the overall height by 870 mm. The folding extension features bars that are arranged closely together. Ropes run between the bars to protect the forage from falling out. Roof ropes prevent the crop from spilling over the top.

Automatic loading

An automatic loading system is available as an option with the dry forage extension. The trigger angle can be set manually and the delay time can be set on the control terminal.

This system ensures optimum loading of the chamber with maximum operating convenience.

Side retention nets

The upper section of the wagon can be lined with nets on the sides to retain the crop and keep the dry forage extension completely clean. These prevent the forage from snagging or falling out. In addition, the smooth nets make it easier to fill and unload the wagon. To fold down the dry forage extension, simply unhook the nets. Because the nets are so lightweight, there are is no shift in the centre of gravity.

Tailgate locking system

To enable unloading even inside low buildings, the opening of the tailgate can be adjusted. Fitting optional struts makes the tailgate open to the rear, instead of upwards. This adjustment is made simply by repositioning one pin on each side.

This allows you to switch quickly and conveniently between the two unloading settings.

Parallel lift drawbar

The parallel lift drawbar on the BOSS 3000 transfers a drawbar load of up to 1.5 ton. As an option it can be adjusted hydraulically and is also available for hitching under the tractor axle. As standard, it can be adjusted to the mounting height of your tractor using adjustment spindles. The narrow design of the drawbar enables sharp turning angles and makes the loader wagon agile. The BOSS 3000 can be hitched to any tractor thanks to the choice of different towing attachments and a drawbar extension. It can also be drawn by tractors with wide tyres or dual wheels.

Drawbar shock absorber

For increased driving comfort, the hydraulic parallel lift drawbar can also be equipped with a shock absorber.

Intelligent parallel lift drawbar with AUTOTAST

If your BOSS is equipped with the Comfort control terminal, you can also benefit from the intelligent parallel lift drawbar with AUTOTAST. With this equipment option, the parallel lift drawbar is permanently controlled in the field depending on the size of the opening between the pick-up and the loading unit. This means it lowers when you drive into a dip, allowing the pick-up to have extra freedom of movement downwards.

When you drive over a bump, the drawbar lifts to maintain the gap between the pick-up and the loading unit. As a result, the pick-up is always in the best position for the maximum floating movement up to a driving speed of 8 km/h.

This is ideal for very demanding terrain.

In addition to the AUTOTAST function, this option also includes memorised settings such as the loading or transport position. It means that you can switch back and forth between field mode and road transport even faster.

Support leg

The support leg is located on the left side of the machine. It is positioned so that it cannot collide with the tractor tyres and the maximum turning angle is equally possible on both sides.

The integrated two-speed gearbox ensures rapid extension and retraction and power-saving lifting of the machine.

Hose holder

The BOSS also makes a neat impression after uncoupling. All hoses and cables can be hung up neatly, preventing them from falling to the ground and allowing them to stay clean. This ensures dirt does not enter the hydraulic system through the loader wagon connections. It makes for quicker coupling and uncoupling, and you stay clean as well.

Separate systems management

While the mechanical part of the driveline is located on the right side of the machine, the electronics and hydraulic systems are located on the left side. Separating the systems in this way simplifies maintenance and cleaning whilst increasing reliability, as there are no hoses or cables near rotating parts.

Functional design

The BOSS 3000 features an attractive, modern and functional design. The large plastic panels can be opened wide. This makes cleaning and maintenance work easy. During the design work, special attention was paid to the loader wagon becoming less dirty and being easy to clean.

Good illumination

Modern LED tail lights ensure optimal visibility of your loader wagon by day and night. Optional LED demarcation lights are available to make the overall size of the loader wagon more visible to other road users. We offer an additional lighting package for working in the dark.

Lighting package

Two floodlights are available as an option on each side to illuminate the area next to the wagon and in front of the wheels. A light inside the loading chamber makes it easier to monitor the loading process. And then there is a floodlight on the tailgate which is helpful when reversing. So you always have everything in view. That means enhanced safety for people and the machine.

Start

The BOSS 3000 DB with beater rotors has a large side access door with ladder as standard.

Access steps

To provide access to the loading chamber, retractable steps are mounted on the rear of loader wagons without beater rotors. In addition, the tailgate can be locked open for enhanced safety.

Ambassador

For decades, PÖTTINGER has been committed to giving farming and the people behind it the recognition they deserve. It is increasingly apparent that food supplies cannot be taken for granted.

The tagline "Everyone needs agriculture!" is intended to create awareness that it is farms that ensure the supply of high-quality food.

This will show the people around you the importance of your work.