Maximum flexibility

×

Modular configuration

All hoe elements have a standardised, modular configuration. To increase machine utilisation, three to five tools can be attached to each hoe element and set to a wide range of row spacings.

The hoe elements can be quickly and flexibly adjusted to the on-site conditions and type of crop. This means that the FLEXCARE row crop cultivator can be specifically adapted to each farm and their tractors.

Short changeover times

High outputs are achieved thanks to short changeover times because the machine is so easy to set up. Independently of varying row spacings, different soil conditions, and stages of crop development, the row crop cultivator can be adjusted to any site-specific conditions in a matter of minutes.

Set the flanged wheels to the track width of the tractor

Position the hoe elements

Align the weeding tools

Set the exact working depth

Adjust the following tools

The most important settings can all be carried out in the field without the need for tools.

The basic version

The FLEXCARE row crop cultivator can handle row widths between 25 cm and 160 cm. The number of hoe elements can be freely selected depending on the machine type.

Up to five tools can be mounted on each hoe element. All weeding tools are equipped with a spring hoe clamped to the adjustment rail.

The basic version of the FLEXCARE is already fully equipped for inter-row work.

Equipment options

PÖTTINGER offers various weeding tools and following tools to enhance the flexibility of the FLEXCARE.

The following tools are available:

Duck foot shares 140 mm, 160 mm or 180 mm

Edging plate 90 mm

Weeding blade 180 mm

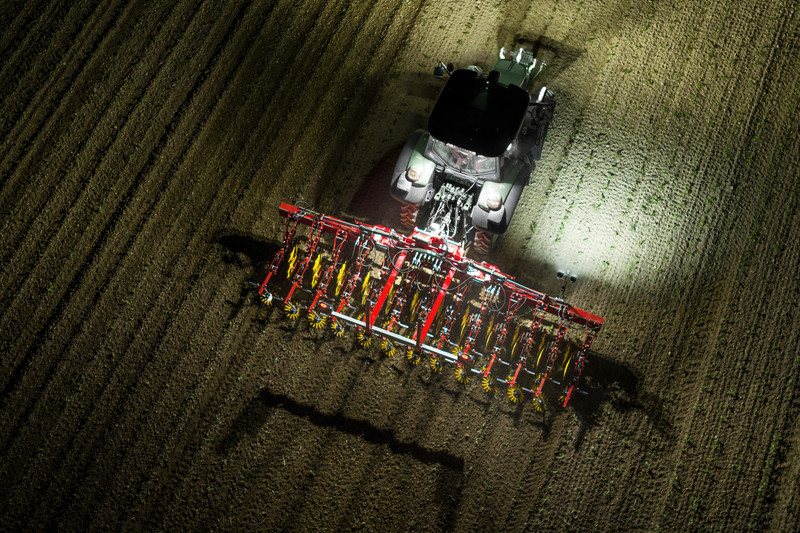

Fully equipped with plant protection discs, following tools and camera guidance, the FLEXCARE row crop cultivator delivers impressive precision and intra-row weeding ability.