The best working results

×

Prerequisites for perfect working results

Perfect results can only be achieved with the right choice of hoe in relation to the sowing width, row spacing and tractor track width. The aim of the process is to work as close as possible to the crop without damaging the crop or its root system.

A decisive configuration

The tractor track width and the number of rows to be processed have a decisive influence on the configuration of the row crop cultivator. With a symmetrical set-up, the same number of rows are located to the left and right of the tractor centreline. With an asymmetrical set-up, the number of rows differs.

In order to utilise the full range of the shift frame even with an asymmetrical set-up, we recommend equipping the FLEXCARE with the optional frame extension.

Asymmetrical: there are more rows to be processed on the right of the tractor centreline than on the left

Symmetrical: there are the same number of rows to be processed to the left and right of the tractor centreline

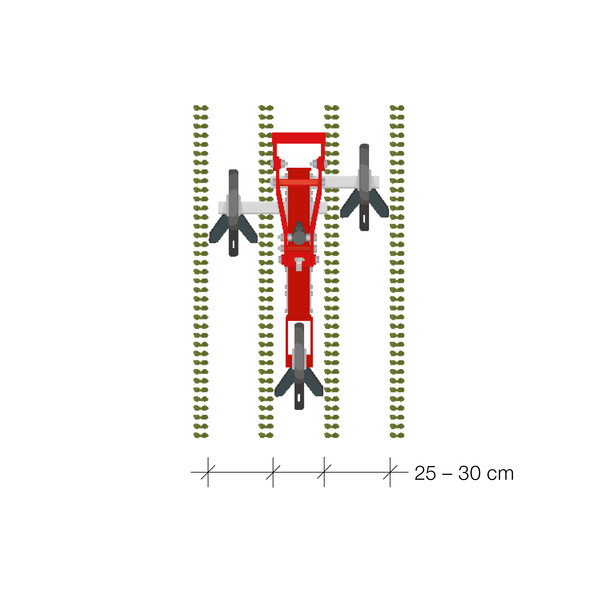

For crops with row spacings of 25 cm to 30 cm, such as cereals or special crops, one hoe tool is used per row. The distance to the row of plants is determined by choosing the width of the duck foot share. In order to minimise the overall weight of the FLEXCARE, each hoe element processes three rows.

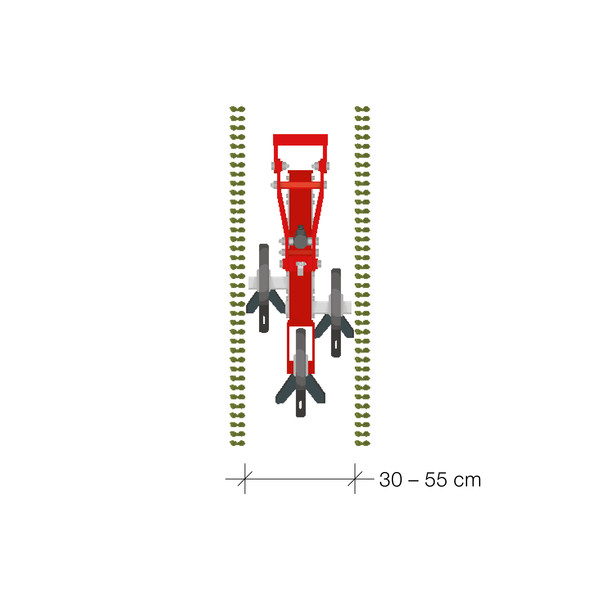

If a row spacing of 30 cm to 55 cm needs to be processed, one hoe element is used per row. For successful weed control between the rows, the hoe element is equipped with three inter-row hoe tools.

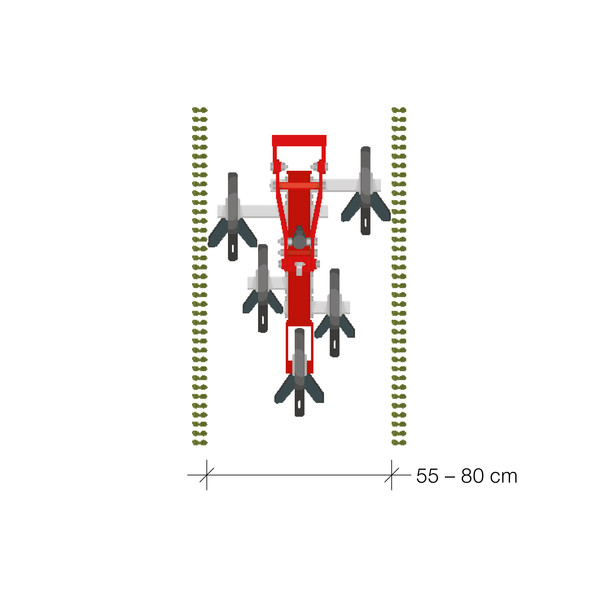

With five hoe tools, row spacings between 55 and 80 cm can be processed. This promotes the growth of maize and sunflower seeds, for example.

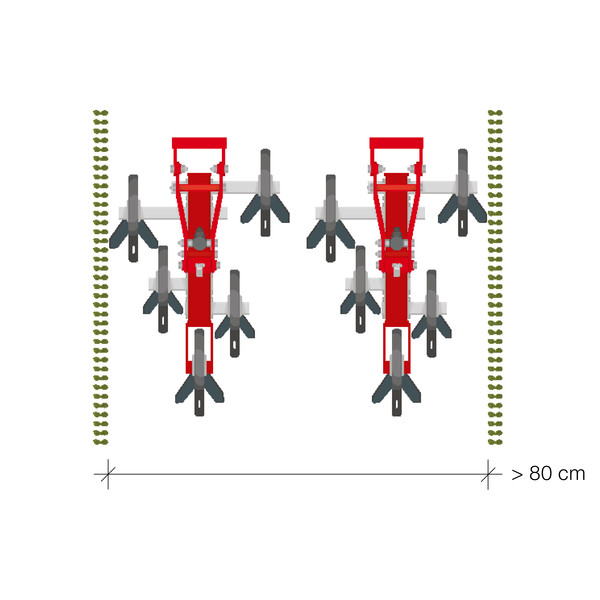

For row spacings wider than 80 cm, two hoe elements per row can be used.