Best seed germination

×IDS - flexibility that pays dividends

The unique IDS system (Intelligent Distribution System) controls all outlets via the bus system. This opens up completely new capabilities in coulter pipe and tramline switching. A must-have for contract work and machinery rings.

It is easy to set the tramlines at the terminal - no need to change the hoses.

The intelligent heart of the system

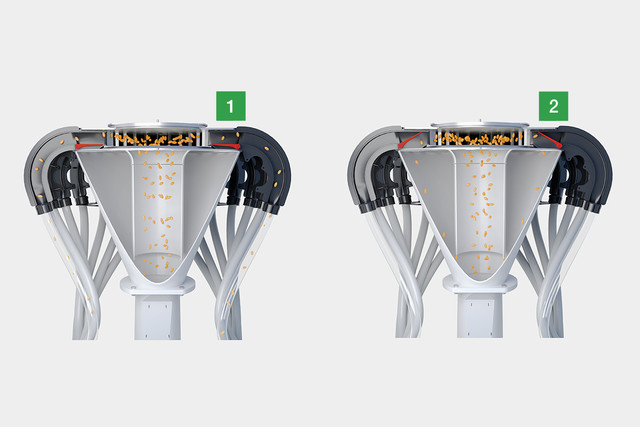

1 The riser tube with funnel-shaped outside conveys the seed material through the distributor head to the outlets.

2 The controlled flaps feed the seed through the patented funnel system into the air stream and back to the riser tube.

With active tramline switching the seed rate is automatically reduced for a seed saving of up to 6 %.

Settings

The IDS distributor head ensures uniform crop growth by maintaining a completely consistent seed count in all coulter pipes.

Tramline widths

Track widths

Special tramline switching

Dual tramline systems

Half width switching left and right

Tramline rhythm can be selected independently of the seed drill width

Reliable & convenient: Tramline switching

Tramline switching is performed electronically using actuator motors. Straighforward setting and monitoring functions using the terminal.

Tramline switching can be symmetrical, asymmetrical or custom.

Flaps on the distributor return the seed to the riser tube so that overall seed output by the metering system is reduced.

Thanks to the free choice of track widths, tramline widths and tramline rhythms, the AEROSEM is perfectly suited for contract work.

Patented distributor head mounting

The distributor head is mounted on three coupling points and is self-levelling thanks to its scissor system.

The distributor head is always aligned vertically both during the folding process and in the working position.

While the distributor head is connected directly to the coulter rail, it is easy to remove and attach the coulter rail.

Optimum seed distribution is ensured because all the hoses are the same length as a result of the distributor head being placed well forward.