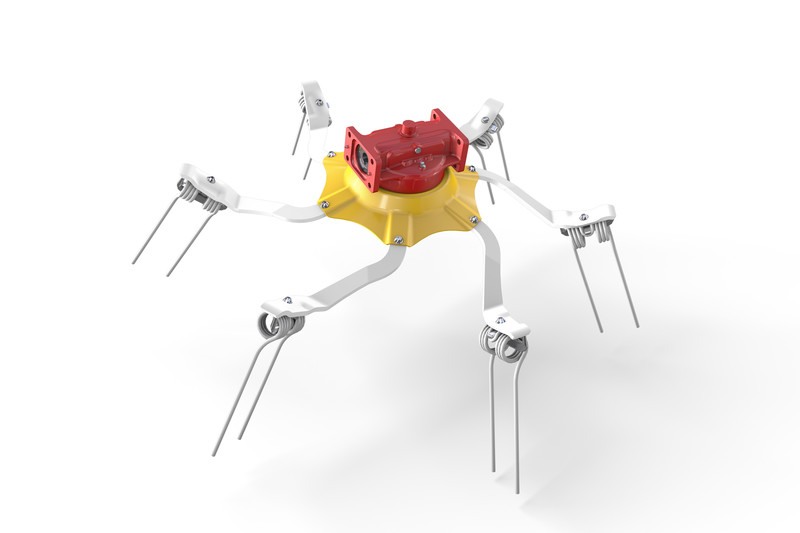

DYNATECH rotor unit

×

Four times cleaner with DYNATECH

The DYNATECH rotor unit is the heart of every PÖTTINGER HIT tedder. The engineered geometry of the tine carriers, a small rotor diameter and the offset length of the tine legs make DYNATECH unbeatable in delivering tedding work that is four times cleaner:

Cleanly collected crop – nothing is left untouched

Clean forage – minimum crude ash ingress

Neat spread pattern – uniform distribution of the forage

Clean machine – rotors remain free of forage

Swept shape tine arms – smooth running, gentle, conserves the forage

The trademark of the DYNATECH rotor unit is the dynamic, sweeping shape of the tine arms. Thanks to this geometry, the tines are guided dynamically through the crop. The result: As a result forage is collected easily and more gently with straight tines and disintegration losses are minimised.

In addition, the sweeping effect protects the sward. If the tines do contact the ground, they are guided in such a way that they have a much gentler effect on the sward and the machine.

The swept shape of the tine arms also prevents forage from building up and wrapping around the rotors. The big advantage being the machine stays clean.

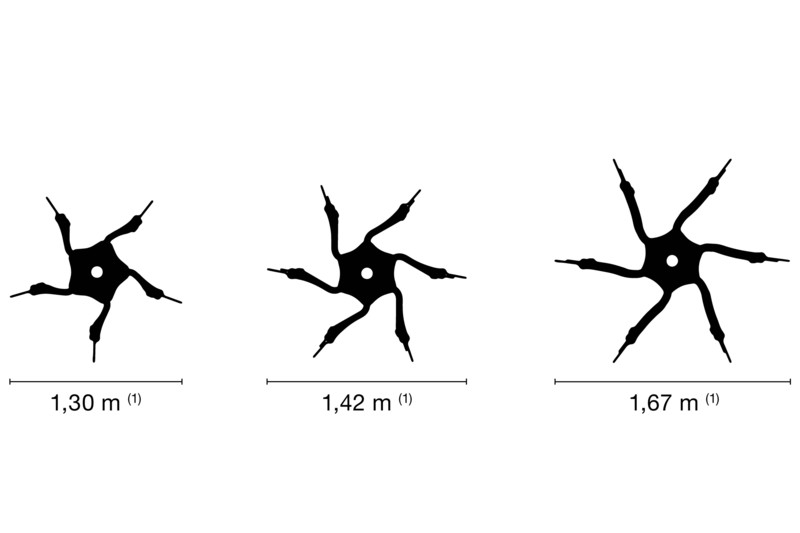

Optimum rotor diameter

The DYNATECH rotor unit not only has impressive tine arm geometry, it also has small diameter rotors. Our most frequently used rotors with a diameter of 1.42 m and six tine arms deliver unbeatable working results, because:

Small rotors adapt ideally to bumpy ground and reduce the amount of crude ash entering the forage.

They pick up smaller portions of crop, resulting in neater forage handling.

You do not have to spread the forage so widely, which results in an exact spread pattern with homogeneous lateral distribution.

They can be operated at lower speeds because they do not have to spread the forage as far. That is how disintegration losses can be avoided.

It's your choice ...

To meet your specific needs, we offer two more rotor diameters in addition to 1.42 m:

1.3 m diameter rotors with five tine arms for our six- and eight-rotor mounted tedders

1.67 m diameter rotors with six tine arms for our four- and six-rotor tedders

(1) Rotor diameter

.jpg)

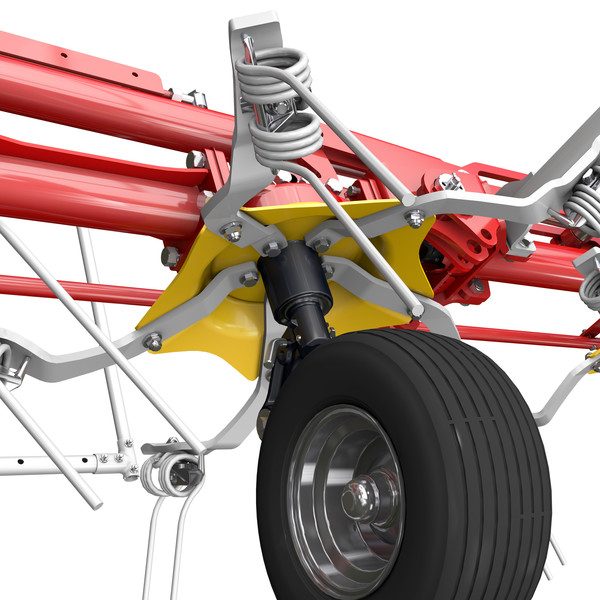

Easy spreading angle adjustment

The inclination of the rotor can be adjusted without the need for tools by adjusting the wheel arms under the rotors in five positions (three positions on the HIT HT 17160). This allows you to quickly and easily adjust the spreading angle to match the forage volume and rate of drying.

For a uniform, clean spread pattern with minimal disintegration losses, a steep spreading angle of approx. 20 ° is ideal for wet, freshly mown forage. A dry crop requires a flatter spreading angle of approx. 12 °.

Strong rotor unit

The rotor dishes are made of heavy-duty, thick-walled pressed components with precise placement for the tine arms. In addition, the tine arms are also bolted to the rotor hubs to ensure an extremely secure mounting.

Huge tine arms

The solid tine arms are made of flat bar with press-fitted holes. These ensure that the tines are held in place securely.

1 Sealed double constant velocity joints

2 Sealed single constant velocity joints

3 Finger coupling only for 180 ° folding

4 Sturdy bevel gearboxes