Convenience and maintenance

×

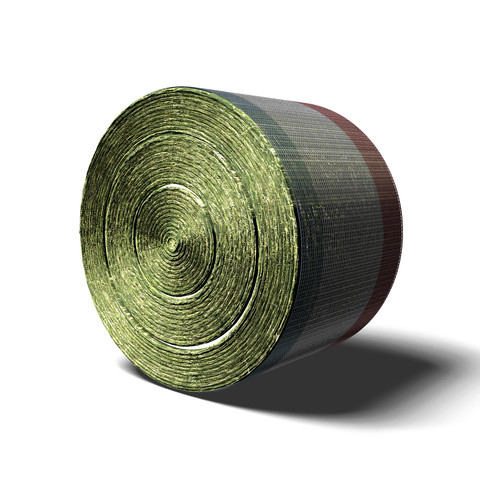

Reserve rolls

All IMPRESS models have two spare roll holders as standard. This means that together with the second roll holder on the binding unit, up to 4 rolls of binding material can be carried on-board.

Handling system

Loading the binding unit means lifting the heavy rolls. The optional handling system makes this process much easier. This turns the right spare roll holder into a loading aid. The roller only has to be pushed onto the chosen roll holder. Sliding rollers simplify the process and protect the binding material.

Lighting

In summer the working days are long while in autumn daylight is scarce. However it works out, with the optional lighting package you'll always have everything in view. The work lights are conveniently operated from the driver's seat using the control terminal. LED floodlights reliably light up the area behind the machine for depositing bales. An LED strip illuminates the intake area of the pick-up and rotor. There are also LED strips with switches under the side flaps and under the binding unit cover to make maintenance and changing the binding material easier.

Camera equipment

The optional camera equipment gives you a better view during bale discharge. Display the image on a compatible tractor terminal or an optional monitor. This can split the screen to display up to 4 camera images simultaneously. Cameras are particularly helpful on steep terrain, as you have a direct view of the bale leaving the baling chamber. This allows you to react more quickly if there is a problem.

Automatic binding

All IMPRESS models start the binding process automatically. The binding process starts with a time delay after the "full signal". The delay time is freely adjustable.

PRO models also have the option of starting the binding process after stopping the baler, so that the process starts automatically after the "full signal" and the tractor has stopped. This ensures that no more crop is fed in.

Automatic pick-up lift

Particularly on steep terrain and in small fields, it is often necessary to reverse the machine. That is when the IMPRESS PRO automatically lifts the pick-up. This makes life easier for the driver and protects the sward. Lifting the pick-up can be triggered either by the binding signal or, if available, by a reversing signal from the tractor.

Automatic tailgate

At the end of the bale binding process, you can have the tailgate on PRO models open automatically. If the machine has a bale kicker, this indicates when a bale is ejected. Once the bale has left the kicker, the tailgate closes again automatically. Shortest waiting times and maximum throughput are thus guaranteed throughout the day, independently of the driver.

Bale catch function

The IMPRESS V PRO can also be equipped with a bale catch function. This opens that tailgate far enough for the bale to be ejected from the chamber, but it is still held on-board the baler.

Automatic chopping system

Blockages cannot be avoided with irregular swaths or when driving at the throughput limit. It is then important they can be removed quickly. On the IMPRESS, simply push a button to relieve the pressure on the knives and release the blockage. When the rotor starts turning again, the knives engage again automatically.

Optional on PRO models

soft core control

The IMPRESS V variable chamber balers have 3-zone soft core control as standard. Different baling pressures can be set in different bale areas using the belt tensioner. This allows bales to be produced with a soft core, a firmer middle zone and a stabilising, higher density outer zone. All parameters such as zone ranges and baling pressures are infinitely variable and are adjusted using the control terminal.

Lighting

The IMPRESS FC and VC models have a floodlight on the wrapper as standard.

An optional LED lighting package makes working in the dark even more convenient. The LED lighting package adds another floodlight to the wrapper. An additional LED strip illuminates the pick-up and rotor area. Additional lights under the covers of the binding unit as well as the film magazines help when changing the binding material and wrapping film.

LED strips are mounted under the baler panels for maintenance and cleaning.

Tandem chassis

The design of baler & wrapper combinations gives them a higher operating weight. Depending on the situation in the field, this can increase significantly due to the weight of bales in the baling chamber and on the wrapper. Conserving the soil at the same time can only be guaranteed by a tandem chassis with large tyres.

520/55 R 22.5" tyres are fitted to the tandem chassis as standard. Depending on the regulations in each country, tyres up to 710/40 R 22.5" can be fitted. Tandem chassis also offer directional stability on steep terrain and a smooth ride during road transport.

Service counter

Who last greased the machine, and when?

Especially with large fleets of equipment and different drivers, these things are soon forgotten. As a result, there is too much or too little greasing. This can affect the service life of many components. With the service counter fitted as standard, the machine keeps track of the intervals itself and informs the driver about the need for maintenance.

Grease lubrication

MASTER models have greasing points for the bearings with short lubrication intervals. On PRO models, these greasing points are supplied by two progressive distributors. This eliminates the time-consuming search for grease nipples.

An automatic greasing system is also available as an option on PRO models. In this case, only the grease reservoir needs to be replenished.

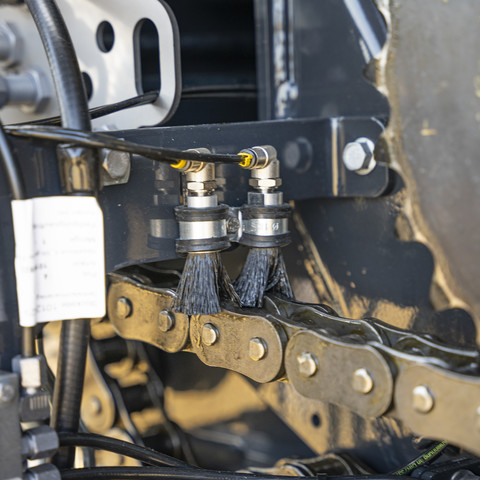

Chain lubrication

Chain lubrication is essential for a long chain life and is therefore fitted as standard on all IMPRESS models. This ensures continuous greasing of the chains and a long service life. The grease volume is preset and only regular filling of the reservoir is required.

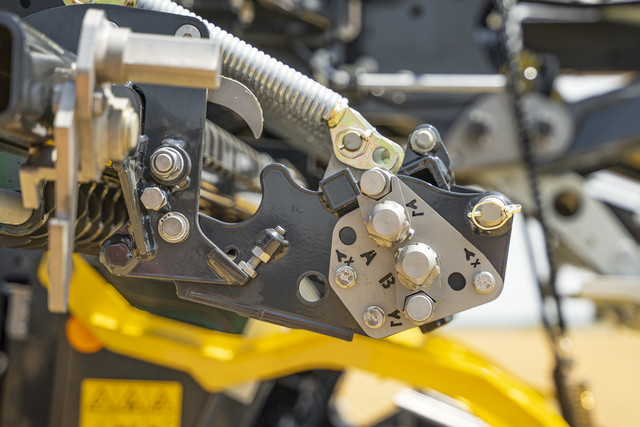

Group switching

The mechanical knife group switching system is standard on IMPRESS MASTER and PRO models. Pre-selection is done by rotating the control shafts with the chopping system lever. The knives are grouped by manually inserting the knives on one of the two control shafts. A fixed position allows the grouping of knives that are always engaged.

As an option, group switching can be done hydraulically on PRO models.

TWIN BLADE

Sharp knives as quick as a flash.

With the standard TWIN BLADE reversible knives, you get twice the service life in one set of knives. In combination with the EASY MOVE pull-out knife bank, changing knives is straightforward and simple, saving working time and motivating employees.

Compressed air cleaning

Leave the dirt where it comes from - in the field. Cleaning with compressed air straight away simplifies cleaning the machine enormously. The optional hose reel with cleaning lance is mounted above the drawbar and can be swivelled through 180°.

This option is available for machines with an air brakes system.

Moisture meter

Moisture determines the storage life of the dry crop. With the optional moisture meter, you can keep an eye on moisture levels at the control terminal over the entire course of the day. This makes it possible to keep baling until the last minute. There is no need to leave the cab and manually measure the bales or to carry a separate measuring device.

Available as an optional on PRO models.