Loading chamber

×Loading chamber

Lowered scraper floor

Lowered scraper floor

The scraper floor has been lowered at the front by 150 mm; this reduces the power required during loading.

When loading begins, a compact, dimensionally stable pack of forage forms at the front end of the loading chamber, and is then drawn continuously backwards by the scraper floor. Thanks to the lowered scraper floor, the pack of forage is also lifted upwards as it is drawn backwards so that the crop fills up the loading chamber perfectly.

The combination of sheet steel and pressure-impregnated wooden elements forms a strong loading area.

In order to simplify maintenance work, the greasing points of the scraper floor shafts are mounted on the side of the wagon where they are easily accessible.

Scraper floor drive system

Scraper floor drive system

The scraper floor gearboxes are centrally located. Hydraulic motors with single or two-speed ratios deliver a maximum unloading speed of up to 24 metres per minute. The scraper floor is equipped with four or six chains, depending on the model.

4 scraper floor chains and 1 scraper floor gearbox:

JUMBO 6620 / 8020

JUMBO 6020 / 6620 COMBILINE

6 scraper floor chains and 2 scraper floor gearbox:

JUMBO 7220 / 10020 COMBILINE

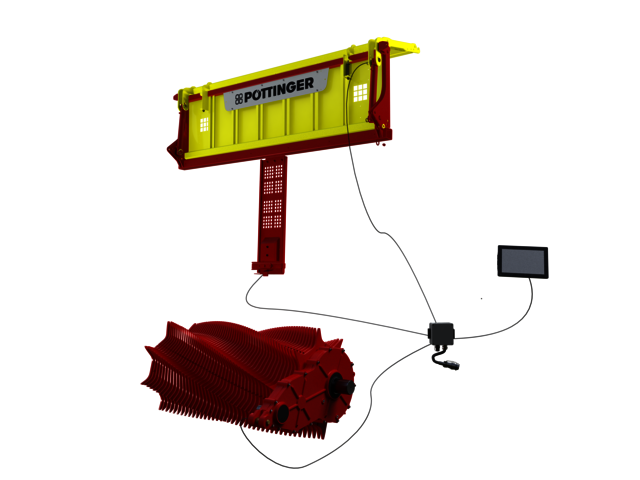

Unload at the press of a button

Unload at the press of a button

The automatic unloading system makes life easier for the driver and protects the machine. A press of a button on the control terminal is all that is needed for the loader wagon to unload automatically. The cross-section of the wide opening enables unloading in less than a minute. On all models, the tailgate opening angle can be adjusted as required from the tractor seat. This minimises the effects of crosswinds and creates a perfect blanket when unloading.

Automatic loading

JUMBO in harvest transport mode

The automatic loading system guarantees that the wagon is filled to achieve maximum transport capacity. The forage is already carefully compressed in the transfer throat to make full use of the loading chamber. You have three convenient loading strategies to choose from.

Advantages of the automatic loader

Two sensors mounted in the front and upper panel sections monitor the loading status. Sensor 1 is installed in the front panel and is set once with the required crop mass pressure. Sensor 2 is installed on the wide forage compression flap and can be set with a time delay if necessary to enable convenient control of the loading performance.

Loading torque sensor

In order to achieve particularly high loading rates, the optional loading rotor torque sensor is very often implemented in addition to the automatic charging system. This is installed in the drive train and enables you to adapt the loading strategy to the dry matter content and forage structure. If required, you can achieve unique loading rates of up to 350 kg / m³.3 reach. This allows you to manage greater field to farm distances cost effectively.

Three convenient loading strategies

Depending on the application, you can conveniently select the appropriate loading strategy from the driver's cab to achieve maximum cost effectiveness. The wagon's comprehensive sensor technology supports you by adjusting automatically to changing conditions.

Loader wagon mode

Loader wagon mode

The wide forage compression flap controls the automatic loading system. sensor measures the pressure on the flap and switches the scraper floor on and off automatically. This protects the forage and ensures the loading chamber is filled right up.

Harvest transport mode

Harvest transport mode

The front flap is folded forwards and provides a good view into the loading chamber from the tractor. This is also ideal for following a harvester into maize. Due to the extremely low pivot point of the flap, you have the best view of the chopped material.

Harvest transport mode

Harvest transport mode

To be able to use the maximum load volume of the JUMBO, the front panel is folded up and the In addition, an optional load containment system is recommended for transport on the road.

Unload with beater rotors

Unload with beater rotors

A uniformly distributed blanket of forage is essential for perfect, trouble-free compaction. That is why JUMBO D models are equipped with a high performance beater driveline capable of handling 160 kW / 220 hp.

The aggressive tines are extremely effective even with highly compacted forage and generate unloading times in the range of 40 - 60 seconds depending on the model and crop.

Unload with beater rotors

Bars integrated in the rollers unload corn chippings quickly and safely. A sensor in the beater roller bearings controls the scraper floor automatically in order to achieve optimum unloading performance while the driver concentrates on other things.

Automatic chain tensioner

Easily accessible, central greasing point

Third beater rotor optional.

Level sensor on JUMBO COMBILINE

JUMBO COMBILINE

This optional sensor on the tailgate measures the filling of the wagon. The filling level is indicated to the driver as a percent value on the control terminal.