Wide range of applications

×

Metering with the highest precision

The TERRASEM metering system is designed for the highest possible precision and ensures that exactly the right amount of any given seed type is used, even in the most difficult operating conditions.

The TERRASEM R3 to C6 have one metering system, while the C8 and C9 have two.

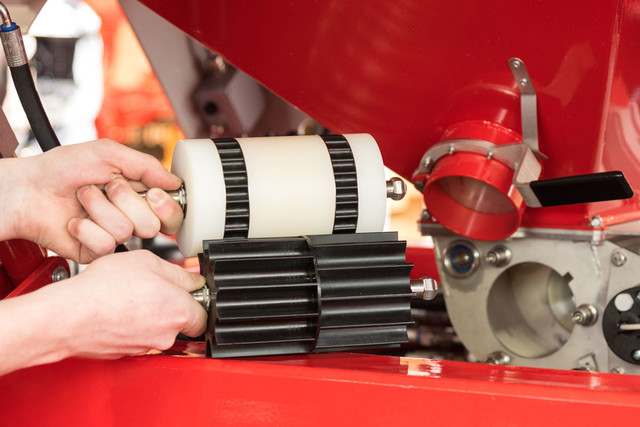

Metering wheels can be changed quickly and easily, dependent upon seed rate and type.

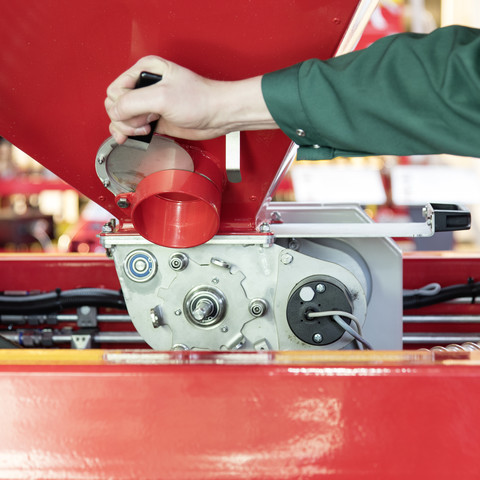

The metering unit is electrically driven, controlled via a radar sensor or ISOBUS signal from the tractor.

Seed output can be set conveniently and easily directly from the cab between 0.6 kg and 350 kg/ha.

Automatic metering wheel control with pre-metering provided as standard ensures continuous drilling and avoids unsown areas.

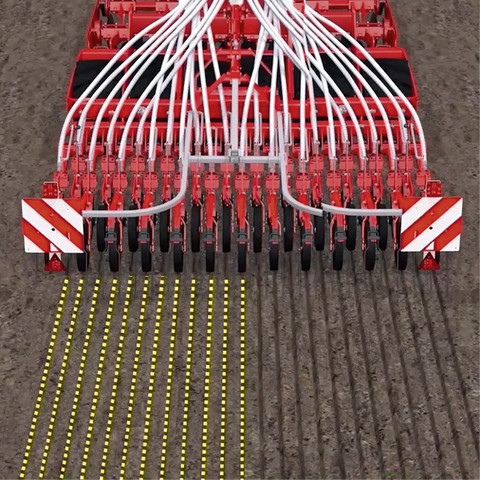

Smooth distribution

A high volume of air and low air velocity protect the seed and any dressing against damage. Together with the precision metering system and large distributor heads, this system delivers uniform seed grain placement.

Maximum effectiveness of seed and dressing is ensured

Special distributor inserts can be used to alter the row spacing.

On the TERRASEM C8 / C9 both distributors are automatically lowered hydraulically during the folding process.

It has never been so easy

PÖTTINGER attaches great importance to user-friendliness. As a result, calibration is easy.

Practical catchment bag

The calibration flap is monitored by a sensor.

Simple and fast emptying of any remaining seed in the hopper is facilitated through the hopper emptying shutter.

Automatic seed flow reduction when tramlines are enabled

Calibration at the press of a button

Infinitely adjustable seed flowrate adjustment

Changeable metering wheels with quick-release connector for all seed types

Hopper level measurement

Fan and metering shaft monitoring

Pre-metering for immediate start at headlands

Seed library

Seed flow sensors for convenience and reliability

The sensor sensitivity can be adjusted in three stages depending on the seed material.

Constant and reliable feedback on seed flow is provided at the terminal.

The status of each coulter pipe is indicated by an LED directly on the sensor:

GREEN: Sensor active and row OK.

RED flashing: Row blocked

The coulter pipe number is indicated on the control terminal

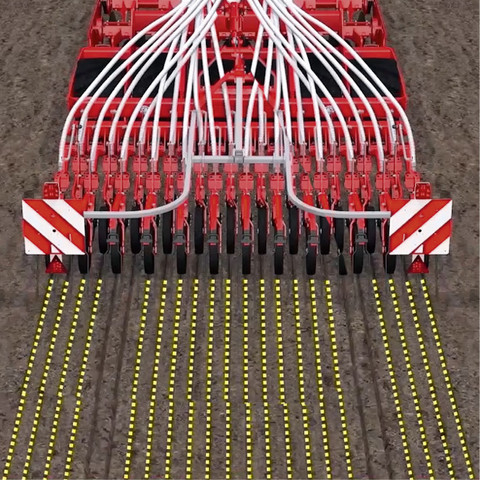

IDS - flexibility that pays dividends

The unique IDS system (Intelligent Distribution System) controls all outlets via the bus system. This opens up completely new capabilities in coulter pipe and tramline switching. Perfect for contract work and machinery rings.

IDS – Intelligent Distribution System

All settings relating to tramline selection can be made easily and conveniently from the control terminal in the cab - no repositioning of hoses is necessary.

Choose any of the following:

Tramline widths

Track widths

Special tramline switching

Dual tramline systems

Half width switching left and right

Tramline rhythm can be selected independently of the seed drill width

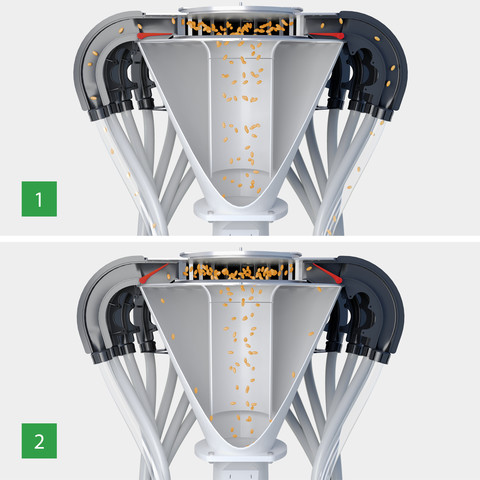

IDS distributor head

The intelligent heart of the system

The IDS distributor head ensures uniform crop growth by maintaining a completely consistent seed count in all coulter pipes.

1 Riser tube with funnel-shaped outside conveys the seed material through the distributor head to the outlets.

2 The patented funnel system with controlled flaps feeds the seed back into the air stream.

With active tramline switching the seed rate is automatically reduced - for a seed saving of up to 6 %

Exact and even distribution across the whole width, even when tramlining

Flexible row spacing

With a standardised row spacing of 12.5 cm, you can generate different row spacings using distributor head inserts.

Implemented for crops cultivated as root crops

Can be expanded to row spacings of 25 cm / 37.5 cm / 50 cm / 75 cm depending on machine type

Flexible use of the machine for a wide range of crops

Shorter dwell time assures less damage to the seed in the distributor head and aids germination when sowing legumes

More features: Tramline switching

Depending on the version of distributor head, symmetrical, asymmetrical or individual tramline switching is possible.

A fully equipped IDS distributor head is equipped with controlled outlets on all seed rows - any tramline rhythm can be set with 2 to 6 rows switched off per track

Half width switching

PÖTTINGER offers the following options for maximum flexibility even with symmetrical tramlines:

Half width switching to the left or right with full IDS equipment

Half width switching to the right only - the right half of the distributor head is equipped with controlled outlets.

Half width switching activated using the terminal

Seed rate is reduced automatically

Enhanced safety on the road

Not only do TERRASEM machines perform well in the field, they are also safe and easy to transport. With a transport width of 3 m, they are approved for the road at any time.

On the road the machine is transported on four wheels, the two centre wheels are raised automatically to improve stability, even on bumpy tracks. High driving speeds on the road are also no problem.

Due to the 15 cm offset of each of the packer wheels, the machines run particularly smoothly. Unevenness both on the road and in the field is compensated by the tandem effect so the machines do not tend to jolt.

Air brakes or hydraulic brakes are available as an option for the weight-bearing pairs of road wheels.

Manoeuvrability at the headland

The purpose-specific mounting enables a tight turning circle at the headland and during transport. The telescopic drawbar is also available with a ring hitch or hammerstrap coupling. These machines can therefore be fitted to any tractor.

Thanks to their telescopic travel of +500 mm, you can run the tractor with twin wheels or wide tyres.

A drawbar extension is recommended in combination with track eradicators.

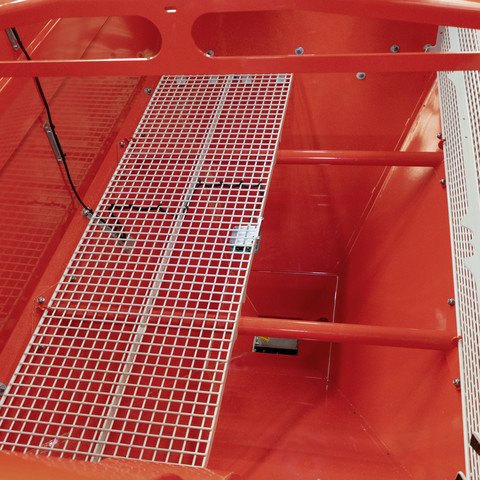

Generous seed hopper for high output

The hopper can easily be filled using a loader, big-bags or an optional hydraulic seed hopper auger. A roll over tarpaulin protects the hopper from dust and rain. This is rolled up out of harms way to save space.

The standard loading platform makes it easy to open the hopper cover to check filling progress.

The mesh inside the seed hopper protects the metering system from foreign objects.

Seed level monitoring of the hopper is standard.

When the roll over tarpaulin is open, it is rolled up small and does not interfere with the filling process.

A seed hopper extension is available as an option.

Seed hopper auger for easy filling

A hydraulically driven universal filling auger for seed and fertiliser is available as an option.

Convenient filling procedure with auger tube mounted in gimbals for easy handling

Seed hopper volume can be utilised completely because auger outlet pivots over whole seed hopper area

The auger is folded upwards and locked securely in place above the seed hopper during transport.

High throughput capacity of up to 470 litres per minute.

Made from cost effective, corrosion resistant stainless steel.