Operation

×

The right control terminal for your work

To meet your specific requirements, we offer three different control systems for your BOSS 3000.

SELECT: Preselect control system

SELECT expansion: Preselect control system with additional control and automatic functions

Comfort control terminal: Power beyond or load sensing operation

With each version, you have the option of operating your BOSS either using a control terminal which is supplied as an option, or using your ISOBUS tractor terminal.

SELECT

The simple SELECT preselect control system enables various hydraulic functions to be carried out using the tractor spool valve after it has been preselected using the machine control system.

The basic system includes the following selectable functions: Raise pick-up, Fold dry forage extension, and activate tailgate.

In addition, there is the option of operating the parallel lift drawbar and the knife bank pivoting system. The scraper floor is controlled using a separate spool valve.

SELECT expansion

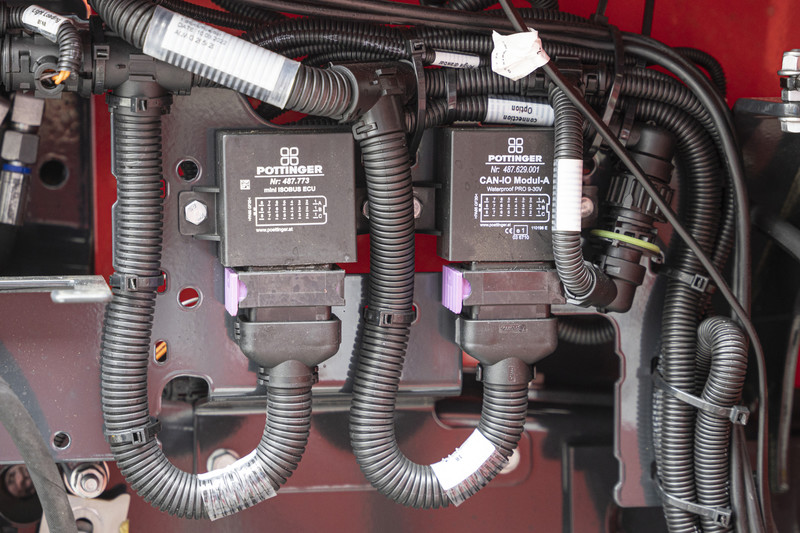

The expansion for the SELECT preselect control system includes controlling the speed and automatic functions of the scraper floor.

The spool valve is then operated in power beyond mode. This then allows the scraper floor to be controlled by the terminal or by the optional automatic loading system. If the wagon is full, then the scraper floor switches off automatically.

This expansion kit also allows a lighting package to be installed. 35 l/min oil flow rate required.

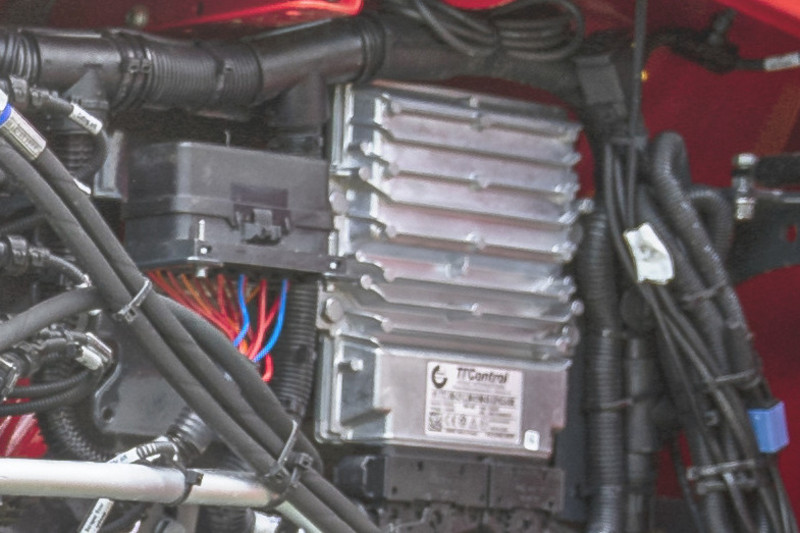

Convenient operation

The top level system controls the entire hydraulic system using power beyond or load sensing. This means that all functions can be performed directly from the terminal. In addition to the optional automatic loading system, an automatic unloading system is also included. The comfort control system is also needed for the AUTOTAST parallel lift drawbar. Machines with hydraulic knife bank pivoting also have a switch on the loader wagon.

Supplied as standard on the BOSS 3000 DB MASTER.

35 l/min oil flow rate required.

SELECT |  SELECT expansion |  Convenient operation | |

Hydraulics requirements | 1 DA 1 SA + 1 FRL | 1 DA 1 SA + FRL power beyond | 1 SA + FRL power beyond |

Load sensing | – | – | ■ |

Hydraulic power required | – | > 35 l/min; 180 bar | > 35 l/min; 180 bar |

ISOBUS without terminal | ■ | ■ | ■ |

Terminal optional | SELECT CONTROL | SELECT CONTROL | POWER CONTROL, EXPERT 75, CCI 1200 |

Load counter | ■ | ■ | ■ |

Service counter | ■ | ■ | ■ |

Full-notification | ■ | ■ | ■ |

Scraper floor speed control | – | ■ | ■ |

Scraper floor switches off on wagon full signal | – | ■ | ■ |

Rear switch scraper floor | Mechanical | Electronic | Electronic |

Pick-up activation | Spool valve pre-selected | Spool valve pre-selected | Terminal direct |

Parallel lift drawbar activation optional | Spool valve pre-selected | Spool valve pre-selected | Terminal direct |

Knife bank pivoting activation optional | Spool valve pre-selected | Spool valve pre-selected | Terminal direct / Switch on machine |

Scraper floor activation | Spool valve direct | Spool valve direct / terminal direct | Terminal direct |

Tailgate activation | Spool valve pre-selected | Spool valve pre-selected | Terminal direct |

Lighting package | – | □ | □ |

Automatic loading | – | □ | □ |

Automatic unloading system | – | – | ■ |

AUTOTAST / setting loading mode and transport position | – | – | □ |

■ = Standard

□ =optional

DA = double-acting spool valve, SA = single-acting spool valve, FRL = free return line

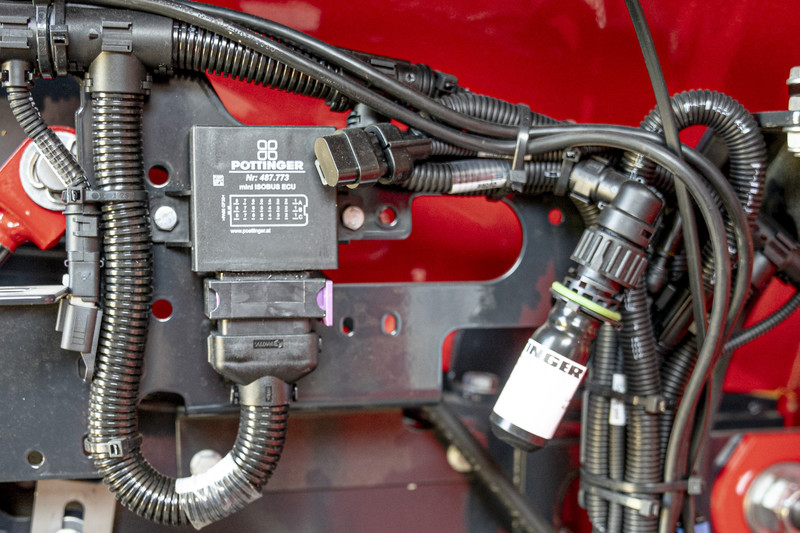

ISOBUS

Every BOSS 3000 is equipped with an ISOBUS connection cable as standard. As a result, even the entry-level version can be controlled using the ISOBUS terminal in your tractor cab. If the tractor does not have a terminal, various control terminals are available as an option.

Simple operation

The AUX CCI A3 joystick makes it easy to control any of your ISOBUS machines. This is done using function keys that can be allocated freely and are separated by ridges. This avoids operator errors. Haptic feedback and all the icons displayed on the keys makes it even easier to work with the joystick.

ServiceCounter

Who last greased the machine, and when?

Because there is always loads to do on a farm, it's all too easy to lose track of machinery maintenance. As a result, there is too much or too little greasing. This can affect the service life of many components.

With the service counter fitted as standard, the machine keeps track of the intervals itself and informs the driver about the need for maintenance.

SELECT CONTROL electronic preselect functions

Optional with Selectline preselect control system

The SELECT CONTROL terminal features a user-friendly design. With illuminated function keys and a 4.3" colour touch screen, many machine functions can be preselected and operated using the tractor's hydraulic remote valves or controlled directly.

POWER CONTROL electronic control system

Optional with Profiline comfort control system

With the new entry-level POWER CONTROL terminal, many machines can be operated using PÖTTINGER's convenient electronic control system. The most important feature is the keys that are printed with the relevant machine functions to ensure intuitive operation for both experienced and newbie drivers.

More functions can be controlled and user inputs made using the 5" colour touch display. Optimised for day and night operation, the display also provides clear information on the operating status of the machine.

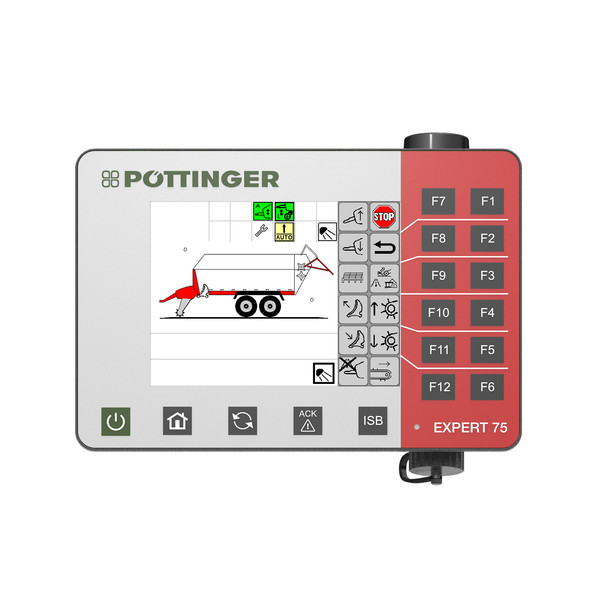

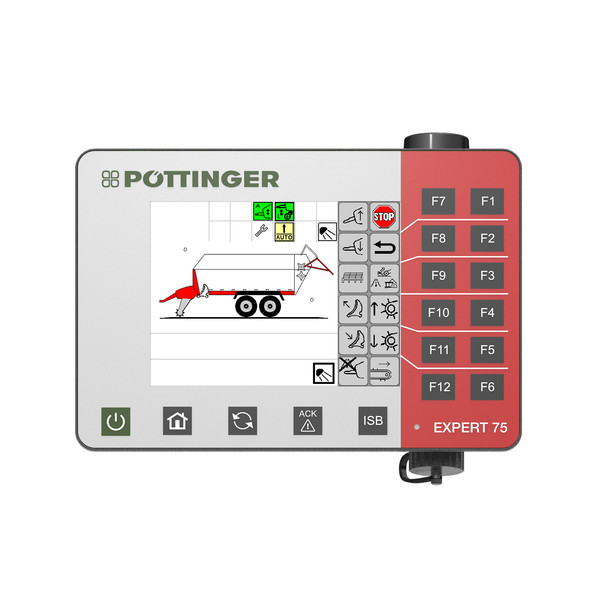

EXPERT 75 ISOBUS terminal

Optional with Profiline comfort control system

The compact 5.6" EXPERT 75 ISOBUS terminal can be operated both directly via the touchscreen and using keys or a scroll wheel. Safe one-hand operation is supported by the grip bar. The ambient light sensor and the illumination of the function keys ensure convenient handling even at night.

CCI 1200 ISOBUS terminal

Optional with Profiline comfort control system

The new 12" CCI 1200 ISOBUS terminal offers the professional farmer a comprehensive function package. The terminal is operated like a tablet using a touchscreen. Navigation is kept simple so you find what you need with just a few taps. The terminal has a camera port. The integrated ambient light sensor automatically adjusts the brightness of the display.