ED tine conditioner / RC roller conditioner

×

The EXTRA DRY conditioner is a joint development with the Institute of Agricultural Engineering (IMAG-DLO) in Wageningen (Holland) that started in 1997 to prove there is better way.

Fast, uniform drying

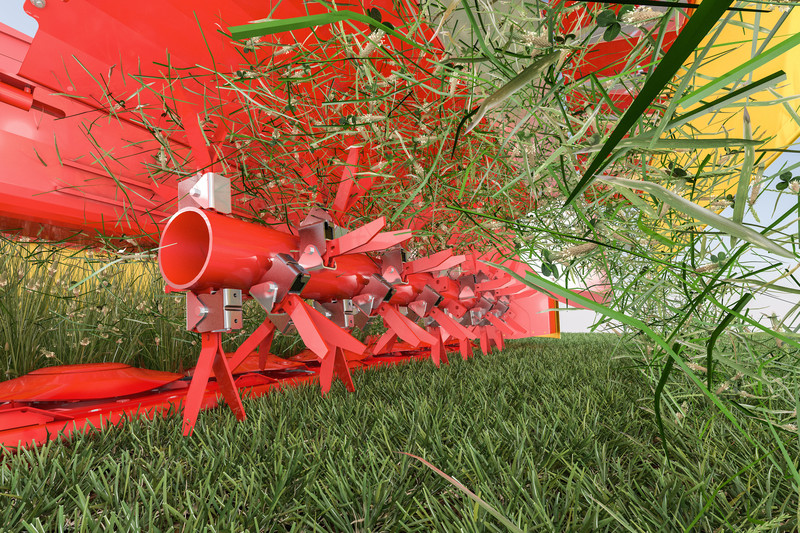

V-shaped tines made of hardened steel hit the stalks in the crop and guarantee a continuous flow of forage.

You can flexibly adjust the conditioning intensity by changing the gap between the tines and the counter flap.

The round, high volume conditioner hood and the adjustable guide vanes enable a loose and airy blanket to be placed.

Adjustable swath doors can be used either for a wide spread blanket or to form a swath, depending on individual requirements.

Long service life

The tines are mounted on rubber blocks that are designed to flex, enabling them to fold back if they collide with obstacles.

Power is transmitted from the cutter bar gearbox to the rotor by V-belts with a spring-loaded belt tensioner. The robust V-belt drive guarantees low weight and a smooth-running drive system

The greasing point is located on the outside for easy access.

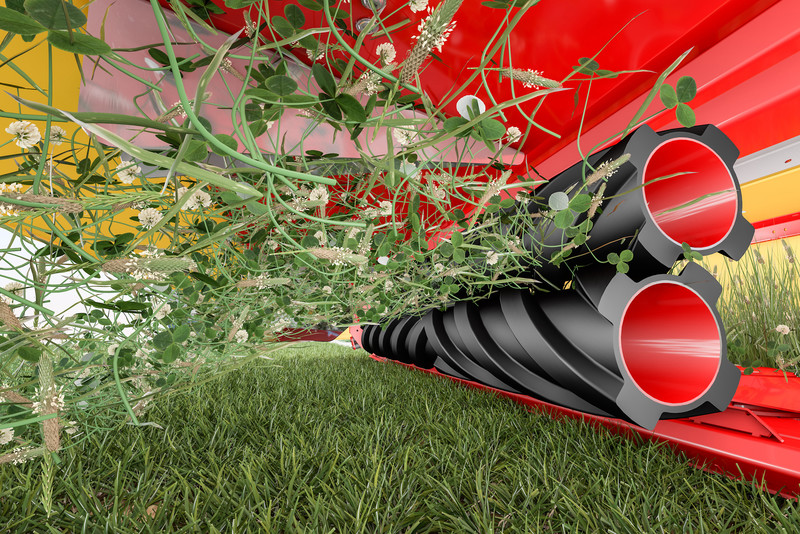

The roller conditioner is especially suitable for alfalfa and clovers due to its precision conditioning capabilities. The helix shape angular groove profile has a high bending and squeezing effect and guarantees perfect forage transfer from the cutter bar.

Careful and effective

The rollers inter-mesh to uniformly crimp the stalks and produce a uniform blanket of forage. Roller spacing is variable thanks to the height-adjustable upper roller. The conditioner pressure can be adjusted on both sides using a hand crank. If foreign objects enter between the rollers, the gap can open by up to 120 mm.

Adjustable swath doors ensure airy and uniform swath formation.

Adjustable swath doors can be used either for a wide spread blanket or to form a swath, depending on individual requirements.

Reliable and durable

The Polyurethane profile is vulcanised onto the robust central tube of the roller The outer diameter is 200 mm. The conditioner profile is tougher than rubber and therefore particularly resistant to wear.

Power is transmitted from the cutter bar gearbox to the rotor by V-belts with a spring-loaded belt tensioner. Both rollers are driven synchronously by a swivel gearbox for maximum throughput. This has a robust construction and is designed for the toughest conditions.

A central greasing point makes servicing easier.

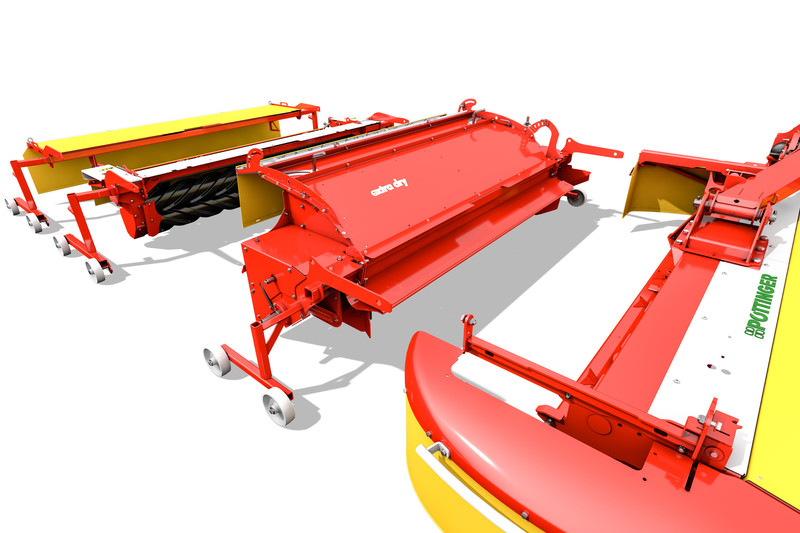

1 mower – 3 possibilities

Thanks to the optional quick-change kit, the tine conditioner or roller conditioner can be removed in a short time on many mowers.

You can switch between the tine and roller conditioner in just a few steps, or install a guard curtain.

How to quickly transform your mower

Take off the V-belt

Fit the conditioner trolley

Undo the conditioner fastenings

Remove the conditioner

Fit guard curtain / alternative conditioner