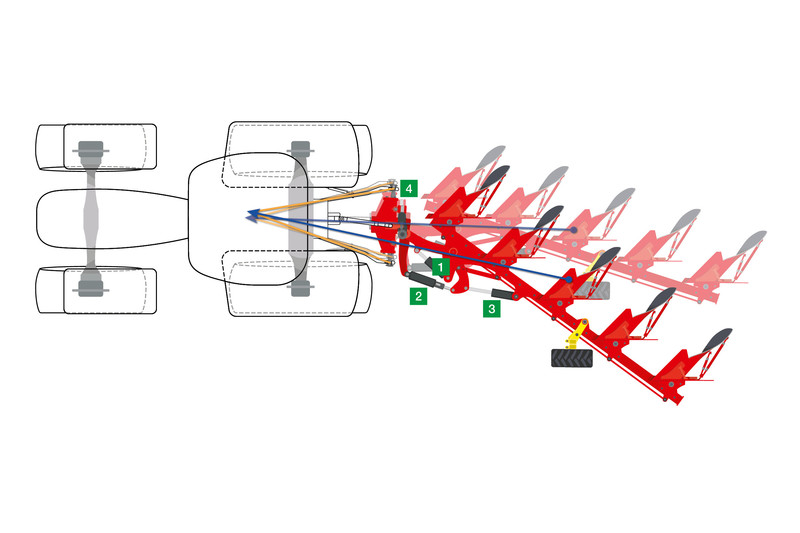

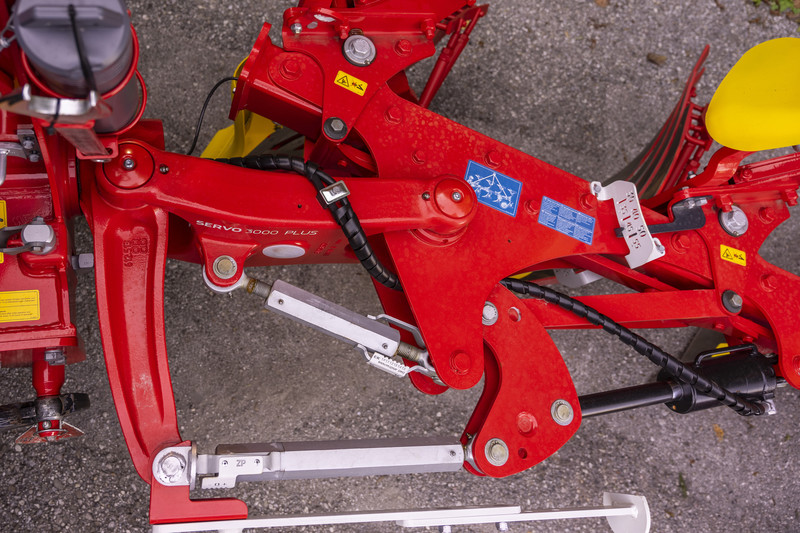

SERVOMATIC control centre

×

1 Front furrow width

2 Pulling point correction

3 Hydraulic furrow width adjustment

4 Beam angle

Front furrow width

While designing the SERVOMATIC control centre, great importance was placed on a large adjustment range of the front furrow width. The swept shape of the cast yoke covers a wide adjustment range for different tractor inside track widths between 1,000 and 1.500 mm.

The main setting of the updated SERVOMATIC control centre is based on the inside track width of the tractor and is set mechanically using the inside turnbuckle. A clearly visible scale helps to quickly find the correct position based on the inner track width of the tractor. As an option, this can be done conveniently with a hydraulic cylinder.

On SERVO P and N ploughs with hydraulic furrow width adjustment, the four-joint linkage automatically adjusts the front furrow when the furrow width is adjusted.

Pulling point correction

To achieve optimum power transmission and to reduce wear and fuel consumption, it is essential that the pulling point of the plough is set up perfectly. A pull line running through the middle of the tractor's rear axle results in a centred power transfer without the plough crabbing to one side or the other.

The pulling point on SERVO ploughs is factory preset for normal working conditions. The tractor's lower linkage arms sway so that the plough is automatically aligned along the optimal pull line, which intersects the middle of the tractor's rear axle.

For special requirements, such as ploughing on steep ground, or to change the landside pressure, the pulling point can be adjusted using a turnbuckle. If a plough beam pivot cylinder is fitted, the pulling point correction is integrated into this by a stop that limits cylinder travel when pivoting in.

Hydraulic furrow width adjustment

As an option, the furrow width of the individual bodies can be adjusted hydraulically. Depending on the point-to-point spacing, different furrow widths are possible. The front furrow is adjusted by the four-joint linkage of the SERVOMATIC control centre so that it is synchronous with the rest of the bodies, and the pulling point is optimised accordingly.

Beam angle

The plough beam angle is set using the beam angle lift, and needs to be adjusted if the furrow depth is changed. The beam angle lift spindle is protected inside a closed guide and can be set without the need for tools.