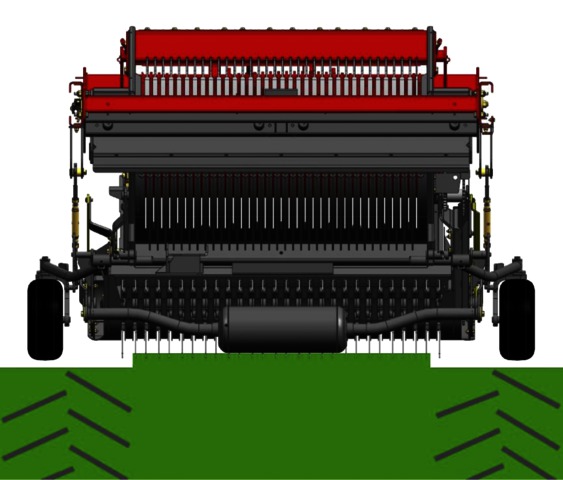

High performance pick-up with 6 rows of tines

×High performance pick-up with 6 rows of tines

Floating pick-up system

Pick-up

Maximum intake

The PÖTTINGER floating pick-up, with six rows of tines, delivers impressive performance. A reliable and high intake pick-up is still achieved at high forward speeds and in difficult harvest conditions.

Floating pick-up

Best ground tracking

Two jointed support arms ensure the pick-up has complete freedom of movement. A spring alleviates the pickup weight so less pressure is exerted on the ground. Height-adjustable 16 x 6.5-8 trailed jockey wheels contact the ground on precisely the same line as the tines to ensure perfect ground tracking and cornering.

Unique travel of 150 mm for perfect ground tracking and exact contouring.

Automatic pick-up reel switch off on TORRO D models with beaters.

Perfect forage flow

Perfect forage flow

The PÖTTINGER pick-up guarantees the maximum feed rate.

A large swath roller with crop transfer rods ensures perfect crop flow and a high loading speed.

The transfer zone from the pick-up tines to the rotor has been optimised and adapted to high throughput.

The rotor conveys the forage smoothly through the chopping system and into the load chamber.

Controlled pick-up for clean forage

Pick-up

Pick-up roller bearings

The pick-up is controlled from both ends by a steel cam track. The sealed twin-race roller bearings fitted to the cam rollers are designed to withstand high stresses.

Clean forage is the result thanks to reduced speed and controlled tine movement. The tines are slightly trailed to sweep in a controlled arc and adapt ideally to contours.

Perfect transfer to the rotor in all conditions with fully active tine length up to withdrawal point.

The forage is not dragged through, so there is less longitudinal alignment of stalks. The result is a much improved chopping quality.

The cam track only needs to be greased once per year. The main bearings have a lubrication interval of 80 loads and are easily lubricated without having to remove guards.

Additional tracking roller behind pick-up

This newly-developed additional tracking roller is located behind the middle of the pick-up on PÖTTINGER loader wagons. Being located in the centre prevents it from sinking into tractor wheel marks and as a result guarantees perfect ground tracking.

The parallel linkage makes all the difference

The parallel linkage ensures significantly improved contour tracking for clean forage, even in difficult conditions. 100% freedom of movement of the pick-up is ensured. The front jockey wheels are adjusted independently.

The additional tracking roller is raised with the pick-up.

Full ground clearance is still ensured.