FLOWTAST

×

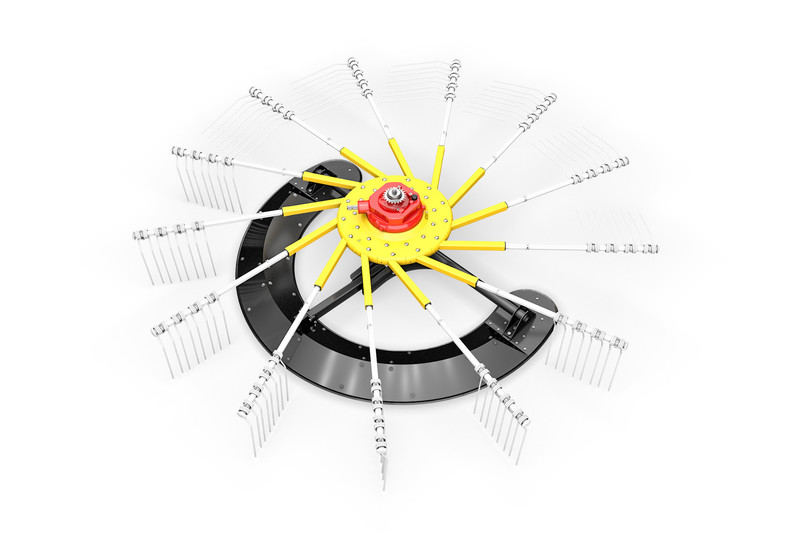

At PÖTTINGER we have developed FLOWTAST, a system that replaces the wheeled chassis with a glide bar for maximum reliability in challenging ground conditions.

Thanks to the large surface area of contact with the ground, deep wheel marks, holes or furrows no longer present a problem. In addition, this system has a larger load-bearing capacity compared to the chassis with wheels. This brings considerable advantages, especially on soft and damp ground.

FLOWTAST is available as an option for the TOP 882 C.

Large area of contact up to the point of tine engagement

Thanks to the large contact area of the glide bar, the rotor unit glides over small indentations in the ground. The distance between the glide bar and tines is minimal. The result: The best tine guidance in challenging terrain.

The rotor inclination is preset using spacer plates.

Hydraulic weight alleviation

A hydraulic cylinder provides powerful weight alleviation for the rotor units. This achieves a ground pressure of approx. 200 kg. This means:

Minimal wear to glide bar

Lower tension on the rake frame

Maximum soil conservation

Smooth running of the rotor unit

The hydraulic weight alleviation system is adjusted using the existing single-acting spool valve. A pressure gauge for reading the ground pressure is integrated into the mounting frame.

Long service life

An extended service life is ensured by the special wear-resistant plastic (PE 1000). Each glide bar consists of 5 individually exchangeable 15 mm thick plates.