SUPERMATIC - BOSS

×

The BOSS 3000 is the perfect choice for farms focused on low tractor power requirements and maximum forage conservation. It can be operated with just 60 Hp of tractor power. The loading unit features proven engineering with 3 or 4 tine conveyor elements and is suitable for harvesting all crops.

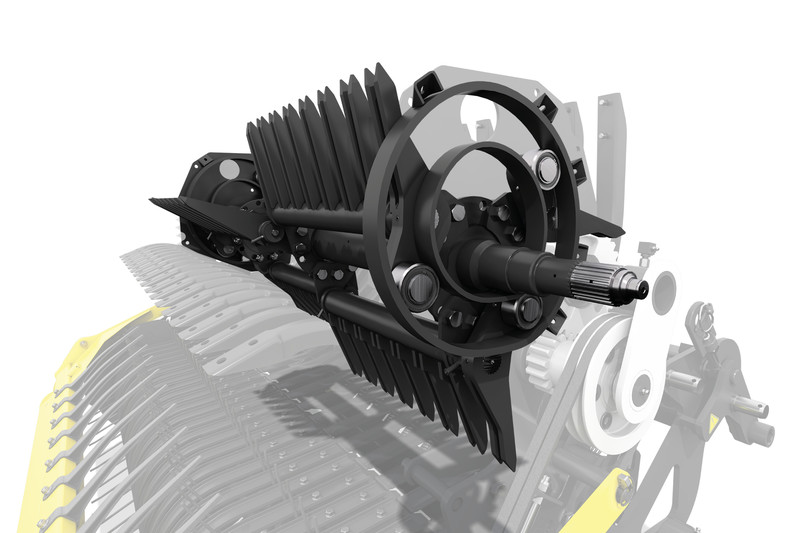

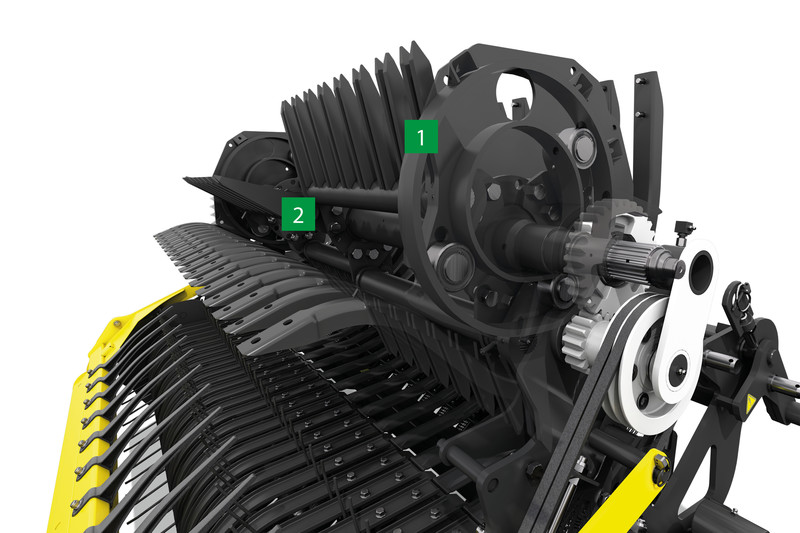

SUPERMATIC loading system

1 Cam track at both ends

2 Centre-split tine conveyors

The classic SUPERMATIC loading unit on the BOSS 3000 achieves a high level of forage conservation and has particularly low power requirements.

The BOSS can be equipped with 6, 16 or 31 knives. Because the forage is guided across each knife by a double tine, high chopping quality is ensured.

The smooth running original – 12 phase

3 split tine conveyor bars and 2 rows of knives result in a 6-phase loading sequence and 2-phase chopping sequence. Each batch of forage is gathered separately and then chopped in sequence as it is conveyed into the loading chamber.

The 3 centre-split tine conveyor bars are mounted on bearings and guided from the outside by heavy duty cam tracks. Optimised for smooth running and the highest level of forage conservation, loading peaks are minimised.

The upgrade - 16 phase

4 split tine conveyor bars and 2 rows of knives result in a 8-phase loading sequence and 2-phase chopping sequence. Each batch of forage is gathered separately and then chopped in sequence as it is conveyed into the loading chamber.

For heavy silage applications with 31 knives, we recommend the SUPERMATIC loading system with 4 tine conveyor bars. This ensures a higher throughput thanks to a faster loading sequence. To keep maintenance simple, the greasing points are grouped together on the system with 4 tine conveyor bars.

Tractor power: up to 110 Hp

PTO speed: 540 rpm; optional: 1 rpm