EVOMATIC - BOSS MASTER

×

The BOSS 3000 MASTER is the ideal choice for farms that need the highest performance in harvesting while spending as short a time as possible maintaining a machine. It can be operated up tractors up to 130 Hp.

With a load capacity up to 27 m³, it is ideal for harvesting hay. The DB version is ideal for high output silage harvesting.

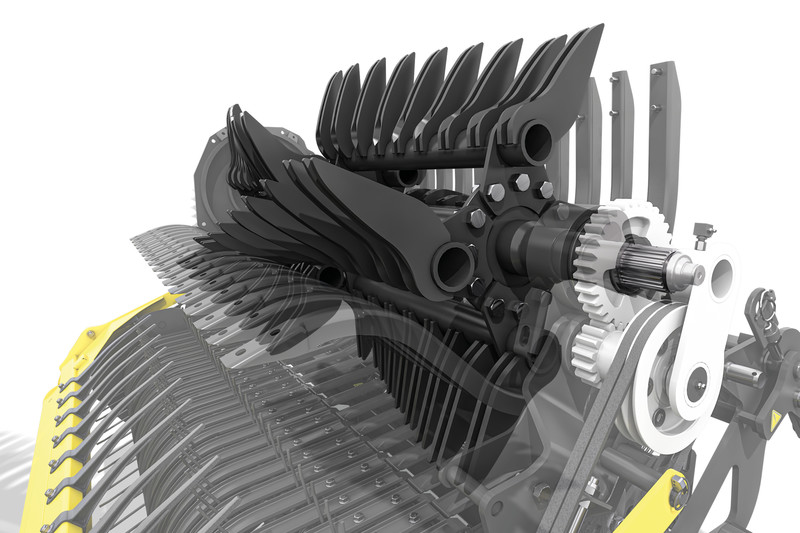

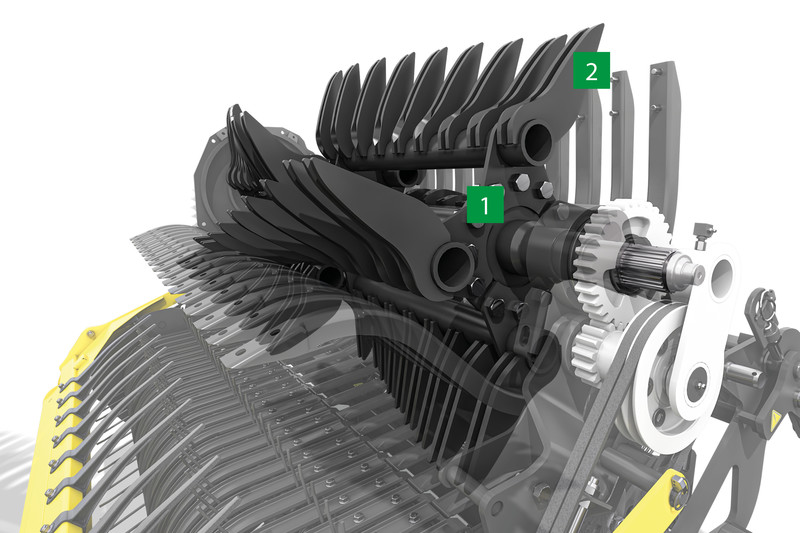

EVOMATIC loading unit

1 Centre-split tine conveyors

2 Double tines

The innovative EVOMATIC loading unit on the BOSS 3000 MASTER delivers approximately 25 % higher loading performance and is impressively smooth running while still ensuring maximum forage conservation.

The powerful innovation - the smooth phase

4 split conveying elements continuously convey the forage through the 2 rows of knives into the loading chamber. Each batch of forage is gathered uniformly and then chopped as it is conveyed jolt-free into the loading chamber. The 4 conveying elements are bolted to a shaft, split in the centre and offset. Wear and maintenance requirements are greatly reduced.

The BOSS MASTER can be equipped with 6, 16 or 31 knives. Because the forage is guided across each knife by a double tine, high chopping quality is ensured. The transfer throat, which opens up to the rear, and the sweeping tine geometry ensure a high level of forage conservation, as the forage easily passes through into the loading chamber.

Tractor power: up to 130 Hp

PTO speed: 1 rpm

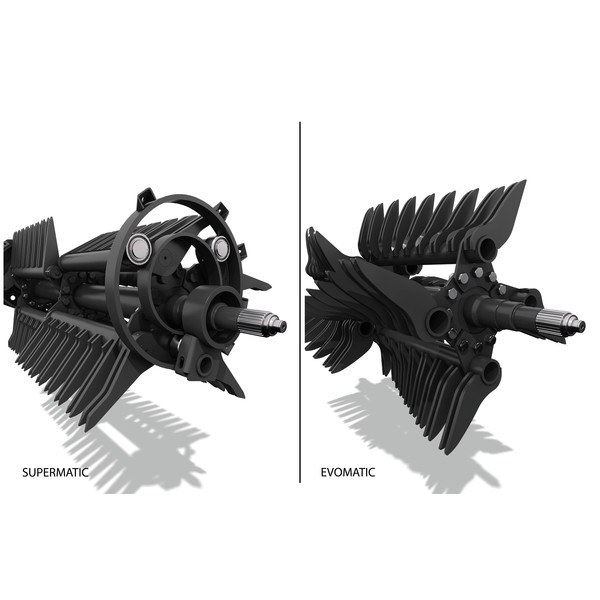

EVOMATIC - the next step in tine conveyor evolution

The EVOMATIC is a completely new loading system developed by PÖTTINGER based on classic tine conveyor technology. EVOMATIC now offers the advantages of the traditional tine conveyor unit engineered for the higher horsepower of modern tractors.

The best of both worlds

The forage conservation of a tine conveyor system combined with the simultaneous chopping and loading performance of a rotor - this is what EVOMATIC delivers. Confirmed by tests at the HBLFA Raumberg-Gumpenstein agricultural college: "The new EVOMATIC loading unit on PÖTTINGER's tine-conveyor loader wagons delivers efficient, high-performance harvesting while maintaining an excellent level of forage conservation." (Source: Pöllinger-Zierler, A. (2022): Comparative tests using a hay loader wagon newly developed by Pöttinger)

As gentle on the forage as a tine

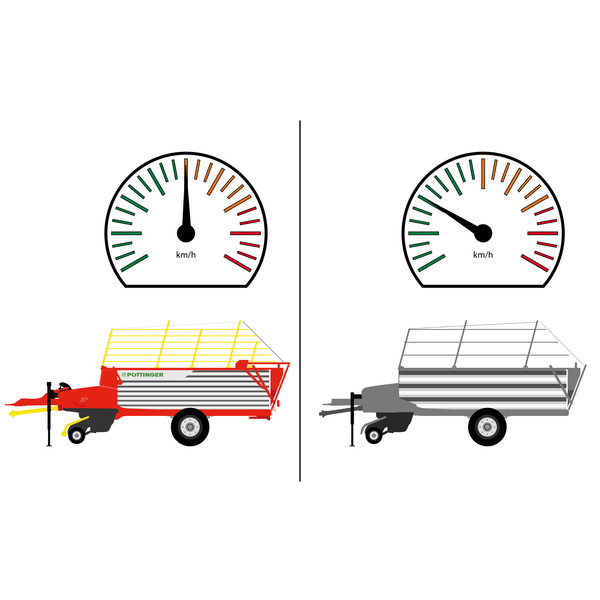

A comparison between a tine conveyor unit and the new EVOMATIC technology showed no discernible differences in terms of disintegration losses.

In addition, the new EVOMATIC loading unit has not been found to cause compaction that might prevent hay from drying properly during ventilation. A uniform drying process, like with material from a tine conveyor loader wagon, is demonstrably guaranteed.

A powerful as a rotor

In terms of loading performance, EVOMATIC together with the controlled pick-up from PÖTTINGER make a dream team.

During the tests, the BOSS 3240 MASTER was able to achieve almost double the throughput rates of comparable loader wagons.

The test procedure at HBLFA Raumberg-Gumpenstein agricultural college

The test results presented are based on comparative measurements in permanent grassland from 2021 and 2022. The crop consisted mainly of perennial ryegrass, cock's-foot, and meadow foxtail. The timing of the cut was at the end of ear and panicle formation. The forage was collected after field drying to approximately 80% DM. The crop was then placed in drying boxes.