Superstructures

×Loading rotor wagon

FARO 5010

You get the smoothest operation, high output, strength and reliability with the FARO loader wagon with loading rotor. The entry-level loader wagon with loading rotor is the most cost-effective choice for harvesting quality silage thanks to its smooth running and excellent chopping quality.

Each type of farm operation expects flexible transport volumes and variable wagon heights.

You can configure the perfect wagon for your business starting from two platform heights with 17" tyres (1,070 mm) and 22.5" tyres (1,190 mm).

Power requirement: 90 to 150 PS

Volume: 24 or 52 m³3

Pick-up width: 1.85 m

Full flexibility with dry forage extension panels

The FARO range offers a wide variety of loading chamber configurations.

To increase versatility, a version with a folded height of 2,960 mm is available in addition to the standard all-steel structure.

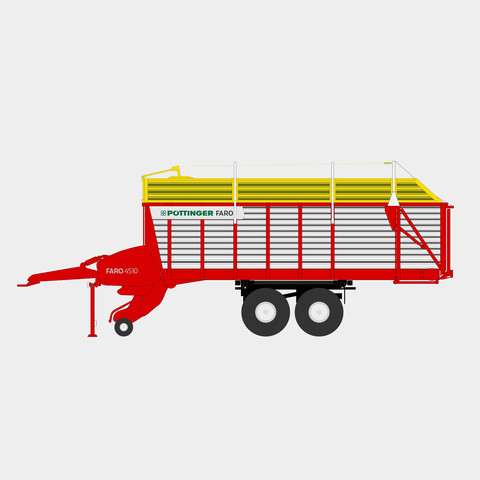

FARO 3510, 4010, 4510

Dry crop extension 870 mm

Basic structure 1,620 mm

Variable height all-steel structure

Three enclosed chamber versions are available.

The advantage of an all-steel structure is that the forage can be loaded and transported reliably and easily in all areas of application without any losses. Low clearance entrances and livestock units sometimes require reduced vehicle heights.

The roof extension bars can be adjusted to lower the overall height.

The profiled plates have a special coating to guarantee a long service life.

The large surface area of the forage compression flap in connection with the optional automatic loading system ensures the best compression of the crop and maximum use of the loading chamber.

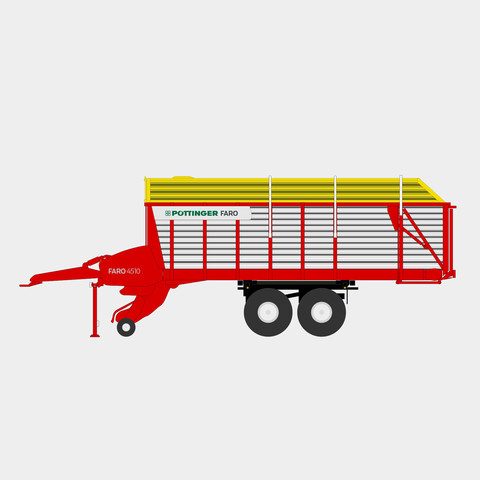

FARO 3510, 4010, 4510

Roof bar 60 mm

All-steel extension 500 mm

Basic structure 1,620 mm

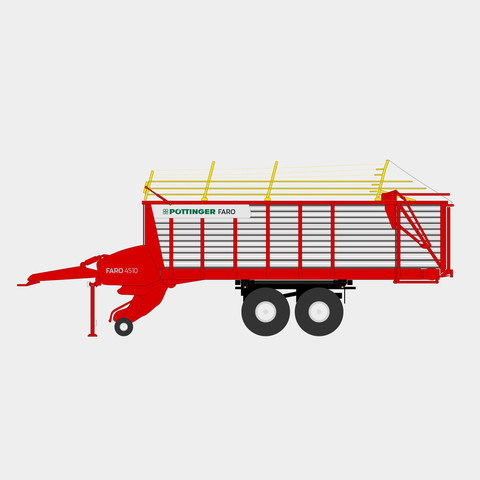

FARO 3510,4010, 4510

Slot-in roof bars (370, 250, 160 mm)

All-steel extension 500 mm

Basic structure 1,620 mm

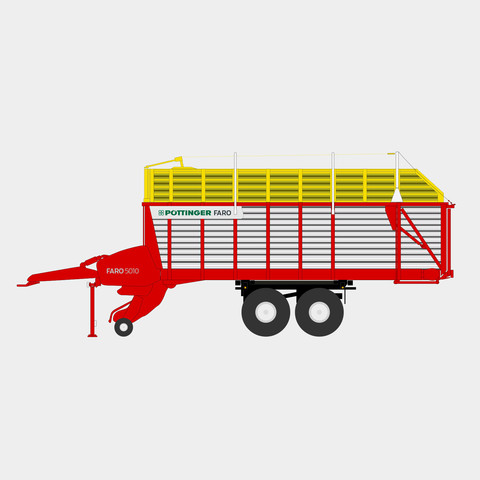

FARO 5010 standard

Slot-in roof bars (370, 250, 160 mm)

All-steel structure 700

Basic structure 1,620 mm

High capacity loader wagon

PÖTTINGER high capacity loader wagons are in a class of their own and have been especially developed for dry crop specialists. This kind of work generally involves large field-to-farm distances. In addition, you often need to clear fields rapidly as soon as the combine has finished its work. Both situations can be handled by the high capacity loader wagon. It is the only way to ensure efficiency and cost effectiveness.

The FARO 8010 L DRY FORAGE and 10010 L DRY FORAGE high capacity loader wagons offer the optimum solution.

FARO 10010 L DRY FORAGE

1 - High volume extension with an outside width of 2.55 m

2 - Large tailgate for an additional loading volume of 1.5 m³3 Load volume

3 - Roof profiles for max. load density with straw

4 - Special tandem chassis with an axle spacing of 1450 mm

Power requirement: 90 to 150 PS

Volume: 48 or 52 m³3

Pick-up width: 1.85 m

Automatic loading

FARO 8010 L DRY FORAGE

The automatic loading system guarantees that the wagon is filled to achieve maximum transport capacity. The forage is already carefully compressed in the transfer throat to make full use of the loading chamber.

Thanks to the consistent loading rate, the automatic loading system provides the basis for high quality ventilated hay.

Sensors mounted in the front panel and upper panel section

A sensor at the lower end of the front panel measures the loading pressure and switches the scraper floor on and off accordingly. This prevents disintegration of the forage as a result of too high pressure at the conveyor tines.

The second sensor in the forage compression flap measures the compression inside the loading chamber.

The forage is compressed uniformly and the loading chamber filled to the optimum capacity.

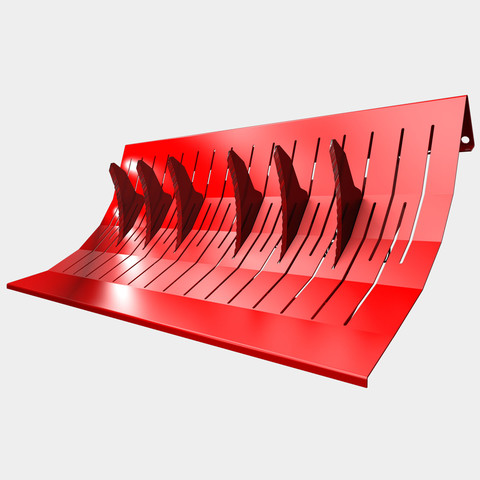

Hay chopping system

6-knife hay knife bank

The 6 knife chopping system creates the basis for the best quality basic ration with the right chopped length.

The trend in hay ventilation requires suitable forage structures. Using efficient technology for harvesting, ventilation and drying will conserve good quality hay and increases the utilisation of its protein value.

The chopping system is also available with 11 knives as an option.

Extension

Roof profiles

The optional roof profiles are fixed to the frame to ensure a high degree of compaction of the crop.

High compression with low density harvest material

Highest capacity load with straw and maize straw

Add-on panels

Add-on extension panels

For large field to farm distances and a high load density, fully enclosing the loading chamber has proven to be a good solution. This effectively prevents forage loss and increases load retention.

1 - Add-on panels

2 - Fit extensions