The highest forage quality

×

Collect everything, as long as it's clean

Intake losses should be kept as low as possible, while at the same time avoiding ingress of dirt that forms clostridia and coliform bacteria in the forage. These cause butyric acid and acetic acid to form, which would considerably reduce the quality of the silage.

That is why harvesting machines need to work as close to the ground as possible without scraping. Maintaining the correct stubble height of 5-7 cm further reduces the risk of dirt ingress, because the implement does not have to work so close to the ground to collect the forage cleanly and tidily. At the same time, sufficient residual assimilation area remains for the grass to sprout again more quickly. If the field is not level, special attention must be paid to ground tracking of the machinery.

Leave nothing behind

The job is done, but the money is still in the field. Disintegration losses are often difficult to recoup. This means plant material that is unintentionally shredded during the mowing, conditioning, tedding, raking and baling processes sinks to the ground between the stubble and can no longer be handled by the following implement. Reducing the machinery speed reduces the risk of breaking up the forage. The drier the forage, the higher the risk. In addition, longer stubble helps to prevent plant parts from falling through to the ground. Alfalfa is particularly sensitive to harvesting. Here, the valuable leaves quickly fall off the stem, which represents an enormous loss of nutrients. However, disintegration losses can never be completely prevented.

A sure thing

Achieving the highest energy content through optimal fermentation is the ultimate goal. Once the energy-rich forage has been collected cleanly, it must be compacted into the bale to avoid air pockets. The chopping quality not only creates a good forage structure, but also helps to compact the bale even more firmly. The shorter the chopped length the better. Once the bale has been formed, it has to be baled. It is important to keep the bale shape and wrap it in film before air pockets can form. If air enters the bale, yeasts form and the forage quality decreases. With round bales, it is like baling a small silo in each bale. These are perfect for mixing different grades and are aerobically stable because they are consumed quickly.

Short chopped length and binding film for the best forage quality

"Our aim is to produce the best quality forage possible - this is very important to us and the IMPRESS is the best choice for achieving this. The 32 knives and top-mounted knife bank (you can change knives while standing) offer us a great advantage over other manufacturers' machines. With the film & film binding, the bale is held together more securely, which also prevents air entering and ensures the best forage quality. In addition, the compact, stable bales are easier to handle during transport and storage and provide better protection against damage. We mainly use the IMPRESS in silage and straw. We have also used it to chop barley straw with 32 knives and got some very positive feedback from our customers."

Thomas & Josef Lustenberger, farmer and contractor Seetal in Ct. Lucerne | Switzerland

With the IMPRESS you can achieve the best possible forage quality. The result is healthy, high-yield animals and clean, invigorated sward. This maximizes your long-term cost effectiveness.

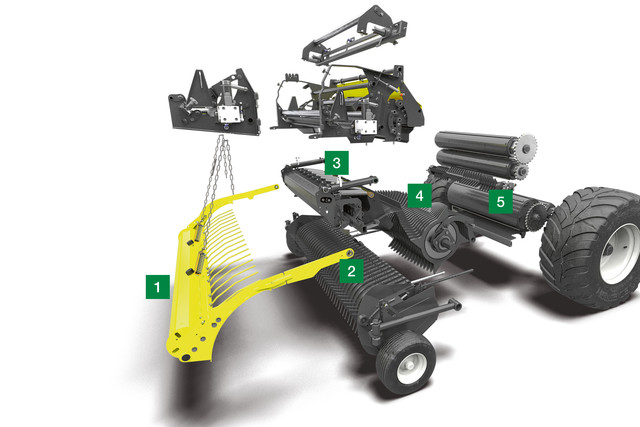

1Swath roller

Ensures a uniform flow of forage

2Pick-up

Collects the food cleanly and gently

3Chopping system

Chops the crop evenly to up to 36 mm across the entire bale width

4Rotor

Draws the forage through the knives and feeds it tangentially into the baling chamber

5Guide rotor

Returns valuable leaf fractions to the flow of forage

Film & film binding

Prevents the bale from expanding after wrapping

soft core control

Enables optimum baling pressure for all applications