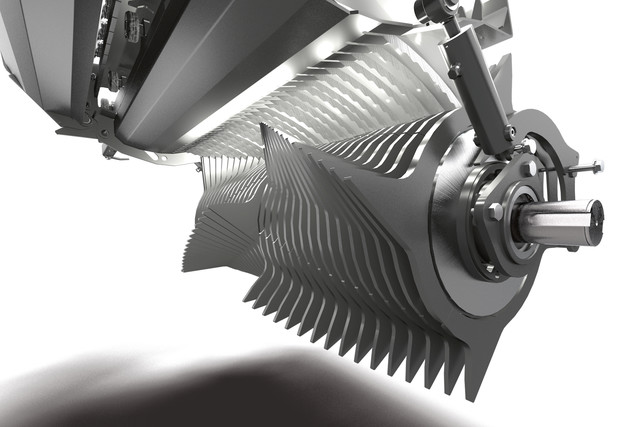

LIFTUP Rotor

×

The special feature of the rotors on PÖTTINGER IMPRESS balers is their direction of rotation. They convey the crop above the rotor. With a diameter of 650 mm, they deliver an enormous throughput capacity.

The design of the rotor is always optimised to the specifications of each model. This means that in addition to a straight forward feed rotor, there is also a choice of two chopping rotors for balers with 16 or 32 knives. The rotor tines are made of high-strength steel to ensure trouble-free and safe operation.

Reliable bale start

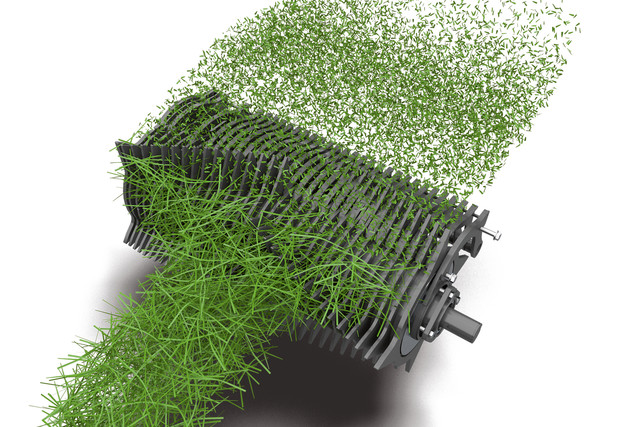

With LIFTUP technology, the rotor guides the forage tangentially into the chamber where it is set in rotation by 4 starter rollers. The rotor additionally supports the rotation of the bale because it constantly feeds new forage in the direction of rotation into the circumference of the bale without deflection.

Top-mounted chopping system

LIFTUP technology places the chopping system above the rotor. The knives are therefore above the rotor. Because gravity keeps the knives clean, contaminated knife slots are history from now on. The knives can pivot in and out reliably and the knife protection system works unhindered. If a blockage does occur in the rotor area, the chopping system floor can also be shifted hydraulically to create additional space.

Wide-spread effect for the perfect bale shape

Thanks to the patented, offset, V-shaped arrangement of the rotor tines, the baling chamber is automatically fed with a wide flow of crop. This reduces the amount of weaving needed to produce perfectly shaped bales. The result is stable, well-shaped bales that make things easier for the driver.

Chopping rotor

The chopping rotor for up to 16 knives has double tines. Each tine has a thickness of 6 mm.

Short chop rotor

An high-strength rotor with 10-mm-thick tines pulls the forage through up to 32 knives.