Chopping system

×

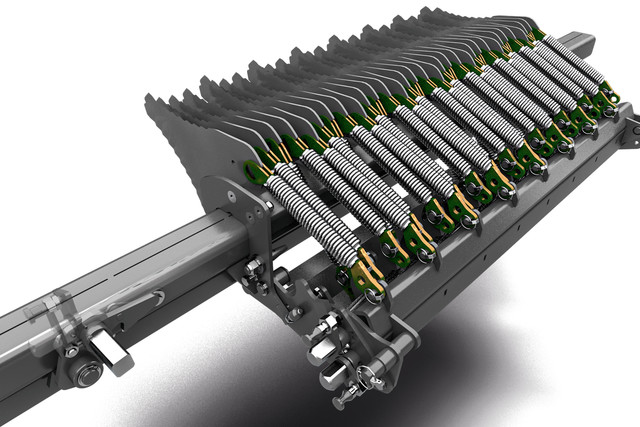

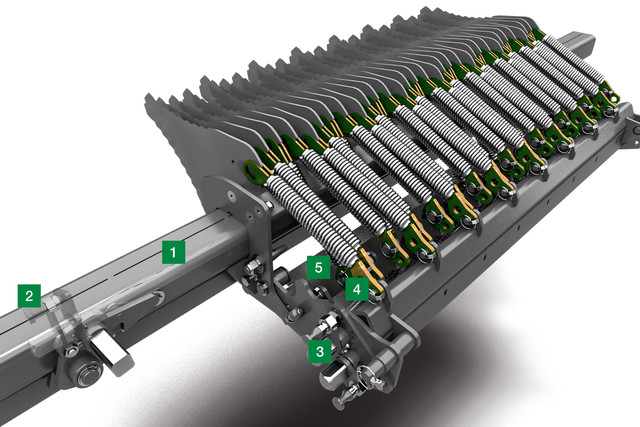

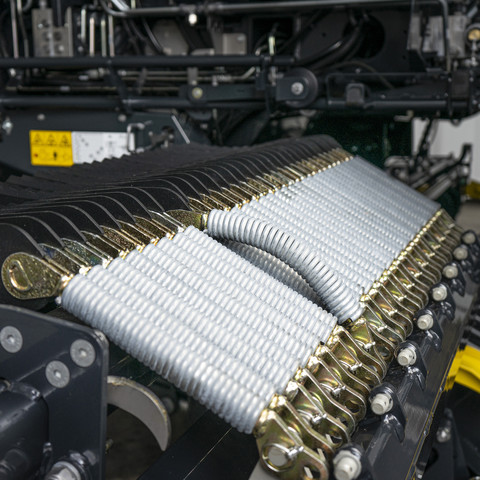

Another key feature of the PÖTTINGER IMPRESS is the design of the chopping system. LIFTUP technology places the chopping system above the rotor. The knives are therefore above the rotor. Two types of chopping systems are available (16 knives on MASTER models and 32 knives for PRO versions). Both are constructed in the same way:

1EASY MOVE - knife draw

More convenience

2Central interlock

More safety

3Knife pre-selection (group switching)

More flexibility

4Fixed knife position (knife always active)

0 to 8 knives

5Knife protection system

Highest chopping quality

EASY MOVE

Unique on round balers

Pull-out or swing-out knife banks are known mainly on loader wagons. The PÖTTINGER IMPRESS now brings the same level of convenience to round balers as well. The result is being able to work while standing in an upright position, out of the tailgate danger zone. Ergonomic and safe.

The knife group selection system can be operated without pulling out the knife bank. Dummy knives are not required thanks to the top-mounted knife bank on the IMPRESS. The knife slots always stay clean.

Knife changes

Changing the knives is quick and easy.

Lower the pick-up and swing out the knives

Remove the hydraulic cylinder, release the knife bank and pull out

Unlock knife.

Turnover, replace or reposition the knife

Secure the knife

Push in the knife bank, attach the hydraulic cylinder, swing knives back in

The key tool, the chopping system lever, is positioned within easy reach on the baler. It is required for mechanical functions such as releasing knives and preselection.

Operator errors are ruled out thanks to a clever mechanism that prevents the knife bank from being pushed back in if the knives are not locked.

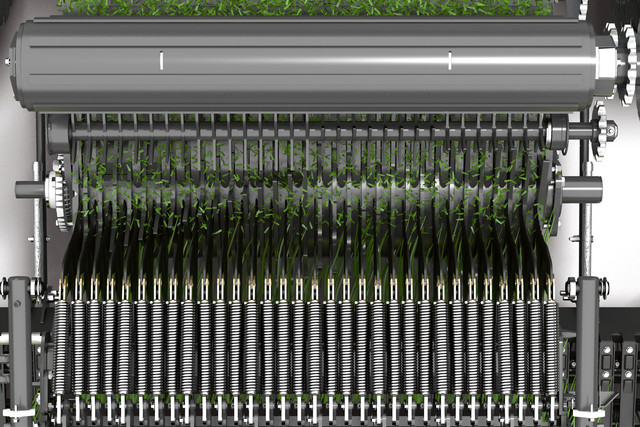

Same chopped length across full width

PÖTTINGER makes no compromises when it comes to the knives at the edge. The chopped length is kept constant over the entire bale width.

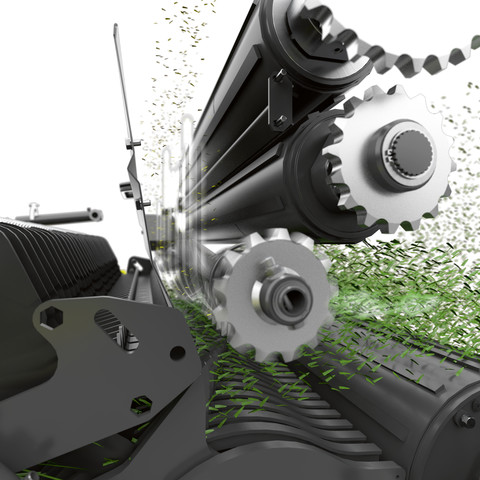

Thanks to the tangential crop flow, the short-chopped material is fed directly into the bale and compacted at high pressure. In this way the bale is built up layer by layer. This gives the bale a very high stability.

Full flexibility - any time

You always have a full set of knives on board and can react quickly to changing operating conditions by simply pre-selecting a knife group to choose from a wide range of chopped lengths. Because the knife slots are always clean (and do not have to be cleaned), changing knife groups is smooth and convenient. This is a major advantage of the top-mounted chopping system.

Always sharp

The TWIN BLADE reversible knife has two blades. By simply turning the knives, a sharp set is again in use. Chopping quality goes up, while the power requirement goes down.

You can relax, because one set of knives will see you through the day.

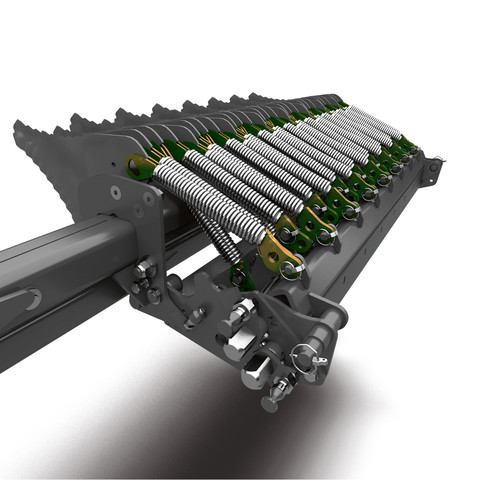

Individual knife protection

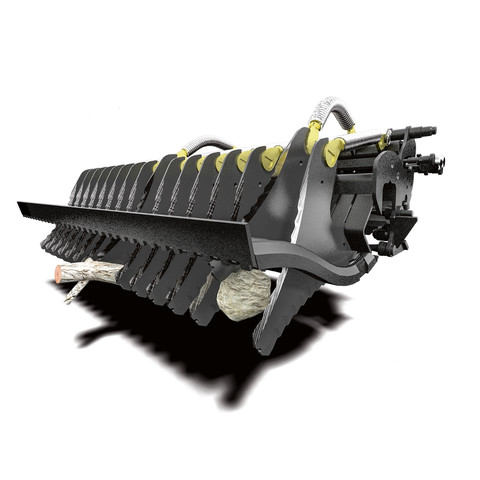

Each knife is individually secured by its own spring. If a foreign object gets into the rotor, it pushes the knife back. Once the foreign object has passed, the knife pivots back automatically. The knife is protected and downtime is avoided.

Knife group selection

With the standard knife group selection system, it is possible to react quickly to changing requirements. You can use the group selection system to either change the chopped length, or keep a fresh set of sharpened knives available.

Group selection options:

MASTER 0 – 16 / 8 / 8 knives

PRO 0 – 32 / 16 / 16 knives

Guide rotor

Short chopped lengths can lead to increased disintegration losses. A chute and a separate rotor actively return the losses into the flow of crop just before it enters the baling chamber.

This is a decisive advantage, especially when used in alfalfa, as the valuable leaf components are particularly rich in nutrients.

Short chopped length right up to the edge

The theoretical chopped length of 36 mm is maintained over the entire width of the baling chamber right up to the edge. The bale can therefore be compacted more evenly. The chopped length of 36 mm is unique and delivers a quality of material previously only available on loader wagons. IMPRESS short-chop bales remain stable even with straw. The binding beyond the edge further stabilises the edges.