Cutting unit

×JUMBO 7000 with a chopped length of 34 mm

With the proven POWERCUT short-chop chopping system, a JUMBO 7000 series is the ideal solution for highest throughputs with low power requirements and the best chopping quality.

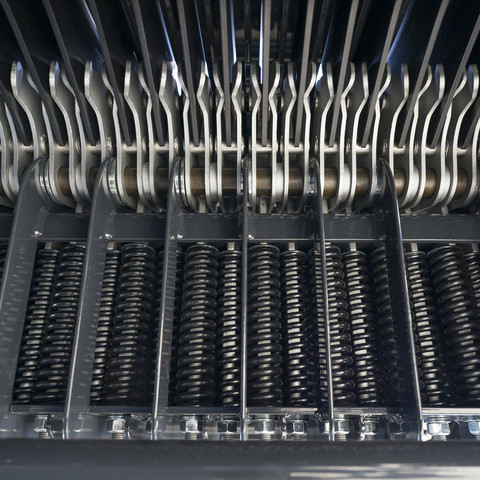

The 48 knives are arranged asymmetrically to the rotor tines for clean and tidy chopping action and are individually protected against foreign objects. These enable a chopped length of 34 mm.

The knife bank that swings out to the side and the hydraulic, central knife release at the touch of a button, are standard equipment on the JUMBO and ensure quick handling without the need for tools.

In addition, the fully automatic AUTOCUT knife sharpening system can be added to ensure that the knives remain sharp for a precise cut at all times.

On the JUMBO 7000, TWIN BLADE knives are available as an option instead of single blade knives.

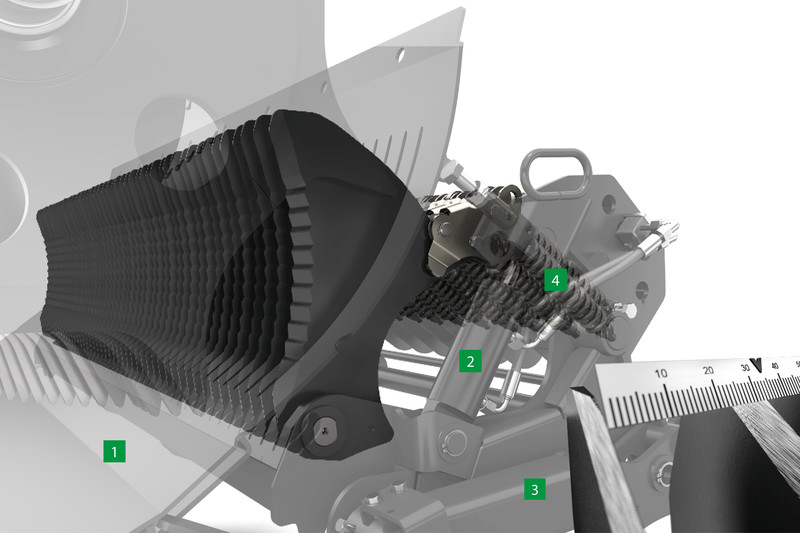

1 EASY MOVE swing-out knife bank

2 Central knife release system

3 Floating rotor support arm, knife bank with position detection

4 Individual knife protection system

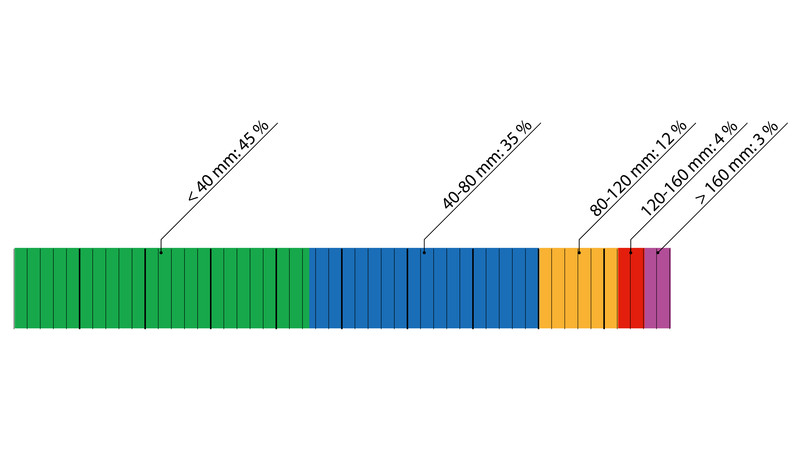

Chopped length distribution*) of the 34 mm short chop knife bank

Stalk length frequency distribution as a percentage of each chopped length range:

*)Source: Study by Josephinum Research 2017

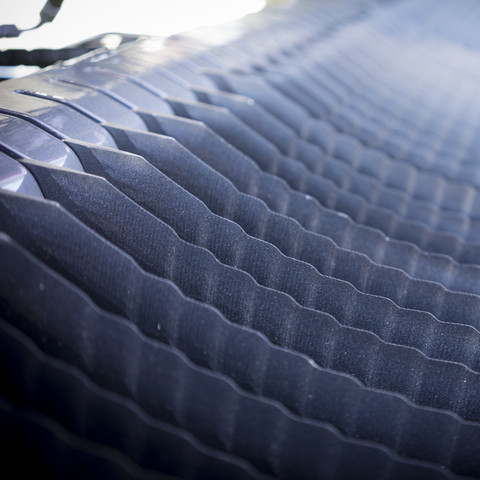

EASY MOVE swing-out knife bank

This unique swing-out knife bank makes light work of changing and turning the knives. Press the button on the side of the wagon to swing the knife bank out. The knives simply swivel out after the mechanical safety interlock is released. Servicing is then safe and easy to perform from the side.

A central hydraulic knife release system is standard. Simply press the release button to disengage the knives so they can easily be removed without the need for tools.

Simply convenient

EASY MOVE lets you change or turn the knives simply and safely outside the loader wagon. It allows you to carry out servicing and inspection ergonomically.

Thanks to this comfortable way of working, knives are checked more often and the loader wagon is always in peak operating condition.

Knife quality

The knives are designed for optimum throughput and made of hardened DURASTAR tool steel. The serrated edge ensures a consistent and precise chop. The extra thick rear edge of the knife guarantees maximum reliability.

Individual knife protection

PÖTTINGER protects your loader wagon with our patented individual knife protection system. Foreign objects are a danger to your livestock and the loader wagon. Moreover, downtime is costly andreduce the quality of the forage.

The triggering force of the knife protection system is adapted to the high throughput capacity. The knives are held in the correct position to make sure that they chop consistently. The knife retention springs and rollers on the individual knife protection system are swung safely out of the way. This greatly reduces the contamination of the knife holders.

1 Foreign objects trigger the protection system. The knife moves in the direction of crop flow.

2 The trigger roller is lifted out of its holder behind the knife.

3 The resistance of the knife is suddenly reduced so that the knife can allow the foreign object to pass through.

4 The knife is then automatically returned to its original position.

Any stones in the forage are not pulverised. The livestock leave the foreign objects untouched at the feed barrier, thus preventing injuries to the digestive tract.

TWIN BLADE

Turnover instead of replace with the optional TWIN BLADE reversible knives on the JUMBO 7000. Its new and patented shape gives you double the service life.

With TWIN BLADE you have a fresh blade to hand without needing to sharpen the knives or to have a second set with you.