Front panel

×

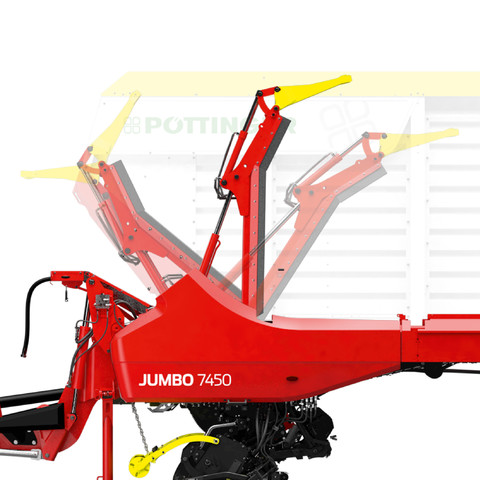

Intelligent front panel

The intelligent and automatically controlled front panel enables a unique loading and unloading strategy. Available as standard, its length of 830 mm means it has a particularly generously dimensioned upper forage compression flap. It provides a significant increase in volume of 4.3 m³ for the same length of wagon.

At the design stage, particular attention was paid to ensuring that the operator has a good view inside the loading chamber.

The front panel makes the loader wagon significantly more compact so that manoeuvrability is improved even in small spaces and on narrow tracks.

An additional dynamometer bolt measures the force acting on the front panel during loading. With the combination of all measuring points (loading torque sensor, dynamometer bolt, compression flap sensor), the degree of compaction and the desired filling level can be directly regulated. As a result, the parameters can be perfectly adjusted to your forage collection requirements.

Intelligent loading system

Three predefined modes can be selected for loading. They enable optimum adaptation to different types of crop, the dry matter content and the degree of filling.

Mode 1: Light load

Mode 2: Medium compaction

Mode 3: High compaction

These three modes can also be individually adjusted to suit your requirements.

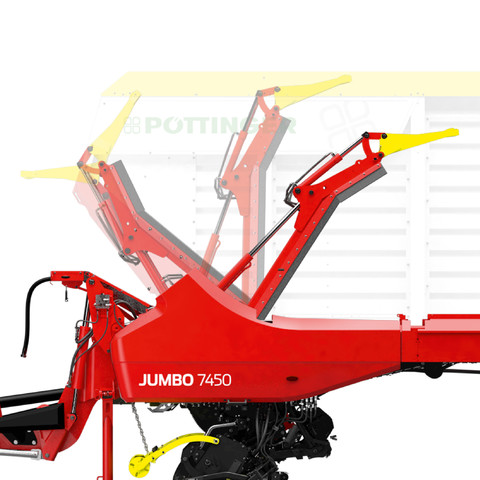

Active forage compression flap

The active upper forage compression flap is another highlight. It regulates the loading pressure and the filling rate and guarantees the highest quality forage.

The control system offers fast and direct adaptation to changing operating conditions.

Filling strategies

Depending on the job in hand and the requirements, the three modes can be selected for the most suitable filling strategy. He can programme his setup with predefined parameters and so vastly improve the overall cost effectiveness of the tractor and wagon combination.

1 Loading torque sensor (JUMBO 7000, 8000)

2 Sensor on forage compression flap (JUMBO 7000, 8000)

3 Dynamometer bolt (JUMBO 7000, 8000)

4 Sensor on the scraper beam (JUMBO 8000)

Loader wagon mode

If the scraper floor is actuated by the automatic loading system, the front panel helps push the forage along and then automatically moves back into the loading position. This patented control system ensures that the forage stays extremely compact.

After reaching the full signal, the front panel pivots forward in three steps. In the process, residual filling is activated and controlled under pressure.

In addition, the intelligent front panel ensures perfect and maximum filling.

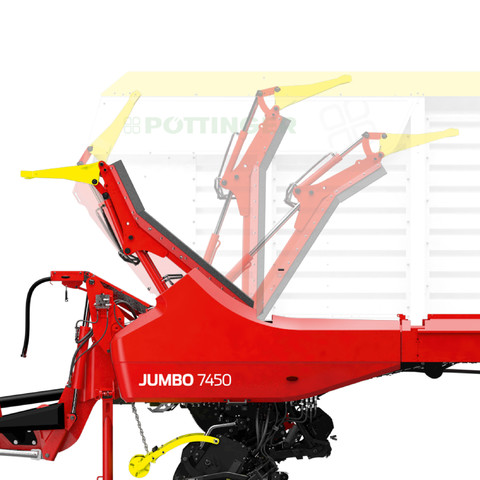

Unload in record time

During loading, the front panel also pivots. It transfers the entire crop to the scraper floor and actively pushes it towards the rear.

The combination of the scraper floor’s hydraulic boost function and the pushing action of the front panel unload even the biggest JUMBO in less than a minute.

Harvest transport mode

In transport mode, only all transport-relevant functions are displayed in the Work menu. In this mode, the JUMBO is driven just like a transport wagon.

To give the driver a clear view from the tractor into the loading chamber or for driving in under the harvester auger in harvest transport mode, the compression flap can be hydraulically folded forwards. Due to the extremely low pivot point of the flap, you have the best view of the chopped material.

An optional load containment system is recommended for transport on the road.