PROFIMATIC PLUS

×PROFIMATIC PLUS

PROFIMATIC PLUS means longer service life.

Conveyor tines

Six or eight offset conveyor tines ensure a rapid loading sequence on PRIMO models.

These loader wagons operate smoothly and offer an above-average loading volume.

The crop is conveyed gently and is chopped precisely without jolting.

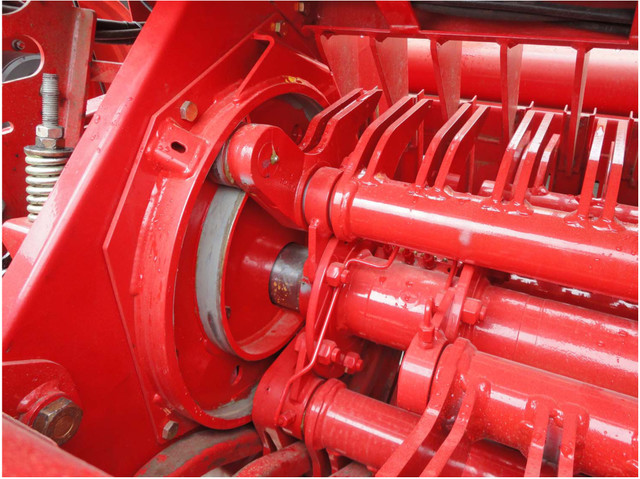

Machined cam track

The conveyor tines are controlled by a cam track at either end of the drive shaft. The inner and outer races of the machined cam track are hardened inductively. Reinforced cam rollers and conveyor tine bearings with over-sized wear bushes offer reliability and an extended service life. Self-aligning bearings are utilised for central shaft.

Loading system

Remote greasing points make for convenient servicing.

Central greasing point for conveyor tines

With eight conveyor tines, an automatic chain lubrication system for the loading system and pick-up is standard.

Short chop for high yield forage

Chopping system

The chopping system is optional, the upper knife bank is equipped with 16 knives, the lower knife bank is equipped with 15 knives. The double-row configuration reduces the power requirement.

A bolt-on frame with 6 knives is also available as an option. Standard at PRIMO 701 / 801.

A maximum of 6 knives are available on the PRIMO 701 and PRIMO 801 models.

EASY MOVE

EASY MOVE

Knife replacement made easy

A hydraulic knife pivot system and the unique EASY MOVE swing-out knife bank are available as an option. There is no easier way to change the knives.

The knives are produced from hardened tool steel and their pressed serrated edge ensures a precise chop.

The extra thick rear edge of the knife guarantees an extended service life.

SUPERMATIC knife protection system

SUPERMATIC

High quality forage

PÖTTINGER protects the heart of the loader wagon with our patented individual knife protection system. The triggering force is adapted to the high throughput capacity. The knives are held securely in the correct position to make sure that a consistent chop length is produced.

Patented trigger mechanism

Foreign objects only move the knife briefly in the direction of crop flow.

The trigger roller is lifted out of its holder at the back of the knife.

The resistance of the knife is suddenly reduced so that the knife can allow the foreign object to pass through virtually unobstructed. The sharpness of the knife is retained.

The knife is automatically brought back into the starting position.

Any stones in the forage are not pulverised like they are in harvesters. The cattle leave them in the trough so that injuries to the digestive system are avoided.