Wear parts

×

Durability

When cultivating the soil, the tillage tools are subject to unavoidable wear. This depends on various factors. Factors that cannot be influenced are the soil type and the different grain size distributions of the mineral fraction in the soil, and the mineral composition of the soil. In addition, soil density and soil moisture play an important role. In terms of the ploughing process, the driving speed and the ploughing depth also affect the rate of wear of the wear parts.

Tillage tools change their shape and geometry as they become more affected by wear, which can also influence the soil penetration angle, the ploughing effect and pulling power requirements. Special alloys, coatings and armour plating guarantee additional wear protection for more consistent work quality and long tool life.

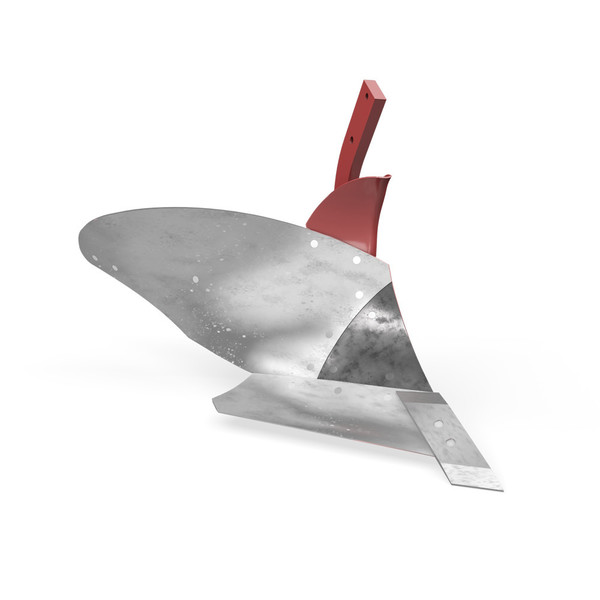

Shins

On full metal plate mouldboards, i.e. without slats, the shins are mounted at the point of highest stress. That is why they are made of 8 mm thick fine-grained steel. Components are through-hardened for additional wear resistance. To ensure the best working results over the long term, the shins can be replaced quickly and cost-effectively.

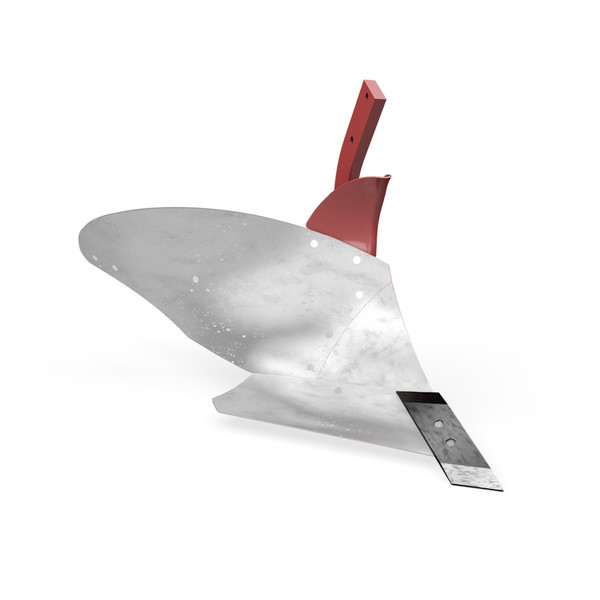

Shares

Hardened boron steel is also used for the share blades with a material thickness of 11 mm. For good soil penetration performance, even in hard soil conditions, the share blades are angled forwards along the shin. Depending on the shape of the mouldboard, they are offered with a length of 16 or 18 inches.

DURASTAR reversible points

The share blades are used in combination with DURASTAR reversible points. These are thermally coated with armoured layers using deposition welding. During this process, tungsten carbide particles are embedded on the surface to form an extremely effective wear protection layer. Because the points can be reversed it is possible to use both sides, which ensures optimum utilization of the material and leads to a longer service life. Reliable soil penetration is ensured because the point retains its shape for a long time.

DURASTAR combined share and point and split share

For extremely hard and stony soils, DURASTAR combined shares and points are recommended, or split shares. The full length share of the combined share and point with its powerful wear tip guarantees penetration into the soil. Combined shares and points are particularly suitable for shallow ploughing. The split shares are similar in geometry and function to the combined share and points. Their advantage is that the point and share can be replaced separately. This means that worn points can be replaced independently of the share blade.