Placement options AMICO F with TERRADISC T

×

Revitalising the soil TERRADISC T with AMICO F

Used in combination with trailed TERRADISC T disc harrows, the outlets feed the material directly into the flow of soil. Because it is then covered immediately, emissions during fertiliser application are prevented, while stimulating the germination of cover crops. Even at high driving speeds, precision distribution is achieved across the full width and seed and fertiliser are deposited reliably.

The angle of the distribution rail with all the outlets is adjustable, and two different placement options are described below. Depending on the application, the distribution rail can be set flatter or steeper towards the ground.

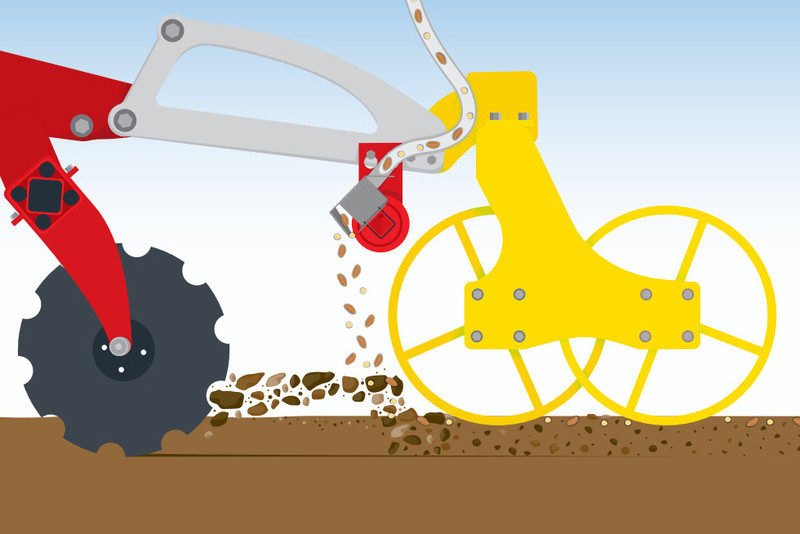

Top placement

Setting the distribution rail with the outlet diagonal to the ground feeds the material into the flow of soil. As a result, the material joins the flow of soil to be deposited on or near the surface.

This method is suitable for sowing greening or cover crop mixtures.

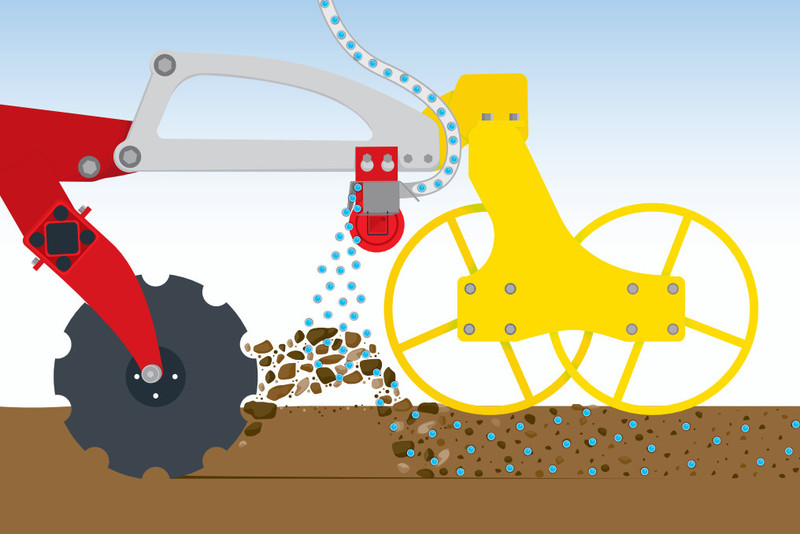

Mixed placement

By setting the distribution rail perpendicular to the ground, the material is immediately mixed into the soil below so that it is deposited across the full cultivation depth. The fertiliser and seed is therefore distributed throughout the entire cross section of soil movement.

During stubble cultivation, for example, compensatory fertilisation of potash or nitrogen can be used to accelerate the decomposition of straw.