Multi-metering system

×

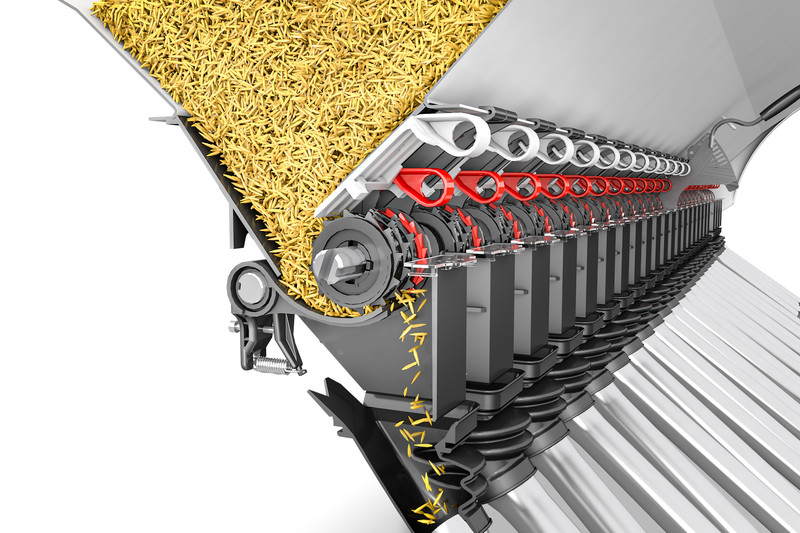

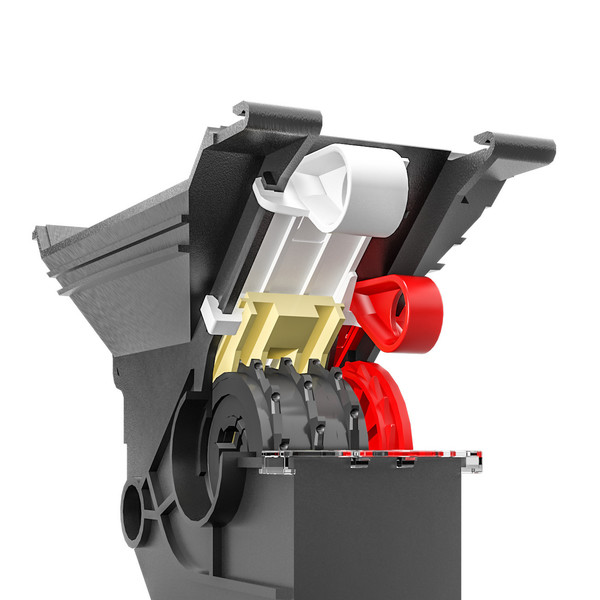

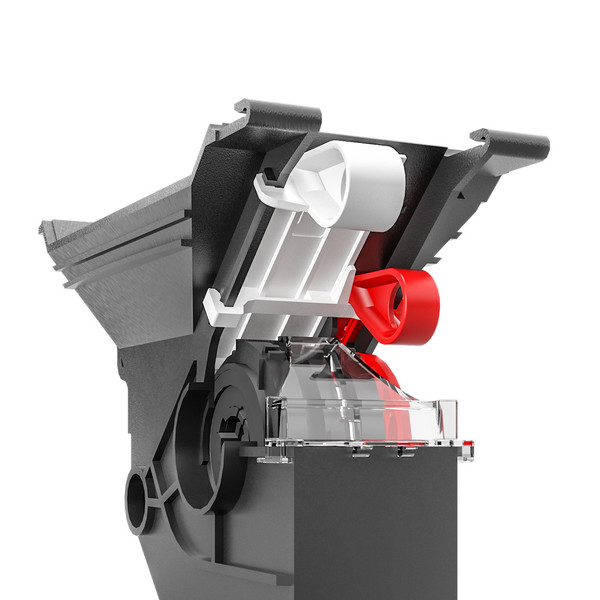

Seed grain size varies enormously. For this reason, a sophisticated metering system is necessary. The combination of the offset 3-row cam seed wheel and the 1-row fine seed wheel enables precise placement of grains of every size. The metering wheels are separated by a partition. A choice of reducer inserts are provided to increase seeding variability. This well-thought-out system makes it possible to reduce the amount of seed needed. At the same time, sowing accuracy is increased by precise distribution of the seed. All possible configurations can be changed in minutes without the need for tools.

Fine seed flow control

Adjusting the speed of the sowing shaft is easy and fast with the step-less gearbox that runs in high viscosity oil. Sowing shaft speed is reduced by half by adjusting the countershaft. With this combination, the metering shaft always runs at a speed suitable for every seed type. This provides optimum seed flow rate control.

Switching an agitator shaft or pendulum shaft on or off guarantees steady material flow and also improves sowing accuracy of seed with sluggish flow rates.

2 Normal seed

The open white slider supplies seed to the black 3-row cam seed wheel. 36 cams ensure perfect seed metering. The partition on the seed flap prevents overflow to the fine seed wheel.

The countershaft enables application rates of 10 to 400 kg/ha with the normal seed wheels.

Suitable seed types:

All cereals (incl. spelt)

Legumes (beans, peas)

Catch crops

Grasses

3 Fine seed

Adjusting the sliders allows switching from normal seed to the standard fine seed in next to no time. The red fine seed wheel has 24 cams with a toothed profile and is ideal for precise metering of the smallest grain sizes.

The lowest seed flow rates of 1.5 to 12 kg/ha are achieved with the fine-gain wheel.

Suitable seed types:

Raps

Mustard

Phacelia

4 Sowing with reducers for mixed seed

Reducers for the normal sowing wheel are available as an option for even lower seed rates. If used, they cover two-thirds of the surface of the normal sowing wheel.

This makes seed flow rates from 3 to 40 kg/ha possible with no trouble at all.

Suitable seed types:

Catch crop blends with coarse-grain seed, for example mixtures with fine-grain legumes

5 Hybrid sowing applications

The reverse metering reducers can also be used for special use cases, such as sowing hybrids. Fully inserted, they cover a third of the surface of the normal sowing wheel.

This makes it possible to achieve seed flow rates from 4 to 90 kg/ha.

Suitable seed types:

Hybrid cereals

6 Reverse metering

Unique amongst mechanical seed drills is the possibility of switching from drill sowing to single seed metering thanks to the option of reverse metering. This entails the use of a reducer and reversing the rotation direction of the sowing shaft by switching the gears in the side drive unit. No tools are needed to do this. Small hollows on the rear of the sowing wheel pegs take only one grain and drop it overhead into the seed funnel.

Seed can be placed individually at ultra-low flow rates of 0.7 to 3.6 kg/ha or 25 to 90 grains/m².

Suitable seed types:

Oil seed rape

Poppy seed

Perfectly adjusted

The flaps are calibrated centrally using seven setting-locks for different seed types. The spring-loaded flaps can easily ride over foreign objects.

A raised partition prevents overflow between the fine and normal sowing wheels, thus guaranteeing maximum sowing precision.

Mechanical metering drive

On the linkage-mounted machines, mechanical metering is driven by the large wheels. On the one hand, this ensures safe operation because the high wheels minimise rolling resistance. On the other, the pressure the machine exerts on the soil is reduced. On the implement-mounted machines, the drive is provided by a spur wheel running within the working width.

Alternatively, the seed rate can be altered electrically on both machine types.

Electric metering

With the optional electric metering drive for implement-mounted machines, seed rates can easily and conveniently be reset from the tractor seat in combination with a POWER CONTROL or a CCI 1200 ISOBUS terminal. The speed signal here comes from a radar sensor on the machine or via the tractor.

The electric metering is activated via ISOBUS. By using application maps the seed rate is variably regulated by automatic adjustment of the sowing shaft speed. This also enables section control and engages the machine’s complete width at the headland to prevent any overlapping.

Calibrating is performed at the touch of a button.

Improve seed flow

The optional rotating agitator shafts are particularly well suited for spelt-like seed types such as hulled wheat. The pendulum agitator is designed for special applications such as grass seed with sluggish flow characteristics.

For rapeseed, legumes and seed types with fluid flow properties there is no need to use the pendulum agitator, especially since its use could damage the delicate grains.