Rotor-type loader wagon with big technology

FARO – smoothest-running rotor wagon in its class for tractors between 85 and 130 hp

Today we present the lighthouse of the loader wagons - "lighthouse" is how FARO is translated in Spanish and Italian. Pöttinger FARO - the landmark in grassland around the world for tractors with 85 hp and upwards. Back in 2005 Pöttinger was the first to recognise the demand for a mid-range rotor wagon and developed the FARO. Proven technology from larger loader wagons has been integrated into these mid-range wagons for alpine operations and smaller farms.

This smooth-running rotor wagon is perfect for bringing in silage as well as hay and straw. FARO 3500, 4000 and 4500 models are ideally suited to silage operations. The 6300 and 8000 models are designed for hay and straw. These wagons feature high output and rapid clearing of the field for larger farms .

Innovative details to meet high expectations

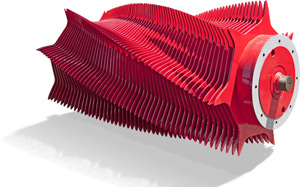

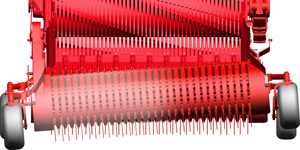

- The ROTOMATIC loading rotor with seven rows of tines arranged in a spiral has a diameter of 750 mm. The theoretical chopped length of the forage is 51 mm; an ideal structure for ruminants

Focus on smooth operation:- Perfect transfer of the crop by the pick-up, even in difficult harvesting conditions (e.g. wet and short forage)

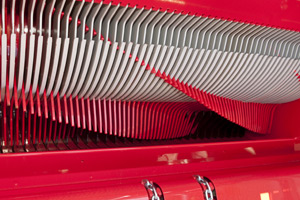

- The double tines penetrate the crop easier than other systems. The gap between the knives and tines is ideally designed to ensure smooth operation as well as protect the knives from foreign objects. (See how the Non-stop knife protection system works)

- Pöttinger also offers the best possible compression in the loading chamber thanks to the double scraper surface area and optimised tine shape. As a result the FARO achieves the highest effective loading performance per m3 in its class – even in damp harvesting conditions.

- Pöttinger takes the lead with the invention of the pivoting knife bank. The Grieskirchen ag-tech specialists were awarded the DLG Silver medal during Agritechnica back in 1999 for the "Easy Move" solution. The Easy Move pivoting knife bank is available on the FARO as an option. No need to even stoop when you change or clean the knives with the knife bank pivoted alongside the wagon. There is no easier or more convenient way.

- High loading speeds require a reliable and powerful pickup. The Pöttinger suspended pick-up with six rows of tines delivers impressive performance – even at high travelling speeds, in all harvest conditions. Farmers confirm that only Pöttinger's controlled pick-up system manages that.

Clean base forage has a higher value:

- Careful crop handling thanks to optimum pick-up speed

- No stones are propelled upwards

- No unnecessary wear to pick-up tines

- Plus: maximum conveyor effect to rotor -> even in difficult harvesting conditions such as in damp and short grass.

- Unloading on wagons with discharge beaters

FARO 3500 and 4000 are also available with discharge beaters. The new, high performance beaters ensure even higher unloading performance and a more even blanket of forage. On all models the scraper floor can operate at up to 18,1 m/min. (2-stage motor as option). Ideal for tight harvesting timeframes - this technology delivers highest performance and cuts down time spent in the clamp. The FARO is available with various configurations to meet different customer needs:- Standard beaters for rapid unloading

- Fine discharge setting (less sensitive to cross wind)

- Third beater for fine control with cross conveyor belts

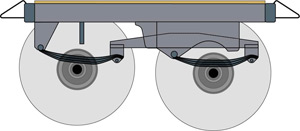

- The chassis – robust and protects the ground

Suspended tandem axles (permissible laden weight 12 t as standard) with the proven compensator linkage ensure stable driving in the field, on the road and in the clamp. The wide suspension spacing of 1100 mm provides safety on slopes and in extreme situations. The chassis is also available with parabolic springs for a laden weight of 13.5 t for even higher stability.

The chassis is also available with parabolic springs for a laden weight of 13.5 t for even higher stability:- Maximum stability on slopes

- At high travelling speeds

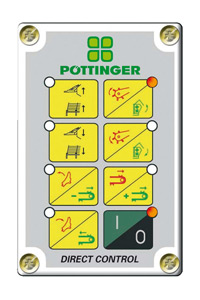

- Self-loading wagons from Pöttinger are well-known for their convenient operation. All the wagon's functions can be controlled electro-hydraulically using the Direct Control operator panel. The new Power Control Terminal also makes operation easier: Raised, illuminated keys make it easier to use in the dark, offering an additional comfort factor. Here you can control all automatic and supervisory functions directly from the terminal. Power Control is supplied as standard on wagons with beaters and available as an option on all other models.

Power Control terminal

Direct Control terminal

Impressive technical details

- The bolted frame construction of the FARO in high tensile fine-grained steel provides the necessary stability with heavy loads

- Wide range of equipment options (chassis, tyres, beaters, etc.)

- Bodywork options: all-steel construction with choice of slot-in extensions plus dry forage version for low entrances (as low as 2960 mm)

- Choice of control systems (with rear control panel for wagons with beaters)

- Automatic loading and unloading for convenient operation – takes the stress off the driver and protects the machinery

Professional users demand reliable quality for a long service life. Ingenious technology, high quality materials and an excellent finish is Pöttinger's answer. The industry leader has set new standards in silage wagon technology with quality workmanship and modern design.