SUPERMATIC

×SUPERMATIC

Crop-friendly loading

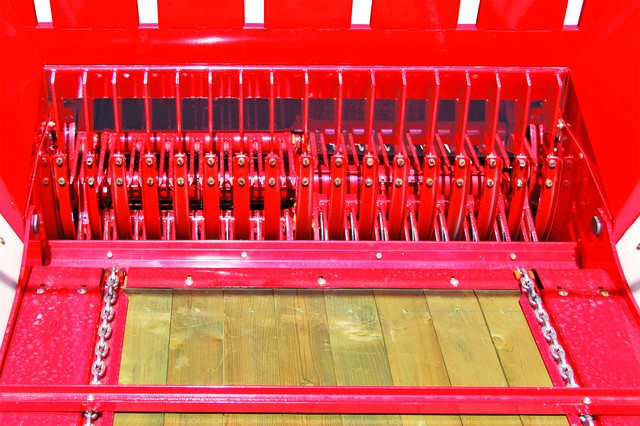

Conveyor system

The large cross-section of the transfer area and the rapid succession of conveyor tines guarantee more than just the highest loading performance. This system is also handles green forage and hay with a great deal of care.

Loading system

Conveyor tines

Cam track

Farmers demand smooth and blockage free loading. Forage is fed smoothly and continuously to the knife bank by split, offset conveyor tines. Centrally split conveyor tines result in a measurable reduction in drag: Separate gathering, offset chopping and staggered feed into the loading chamber mean there are no load peaks even when all the knives are in operation.

The loading system is fitted with three banks of hinged, off-set conveyor tines. As a result, consistent manageable quantities of forage are fed into the knife bank for a twelve-phase chopping sequence.

Summary: smooth loading for high quality forage.

The conveyor tines with hardened bearing journals are mounted on wear-resistant bushes. The cam track is also hardened for an extended service life.

As an option, four phases of conveyor tines can also be supplied on the EUROBOSS for even higher productivity (recommended when using 31 knives). With 4 conveyor tines the tines can be lubricated from a central greasing point.

Thanks to the central splitting and off-set mounting of the conveyor tines, the load is distributed to the cam rollers and cam tracks on both sides. That protects the drive system and is the guarantee for durability.

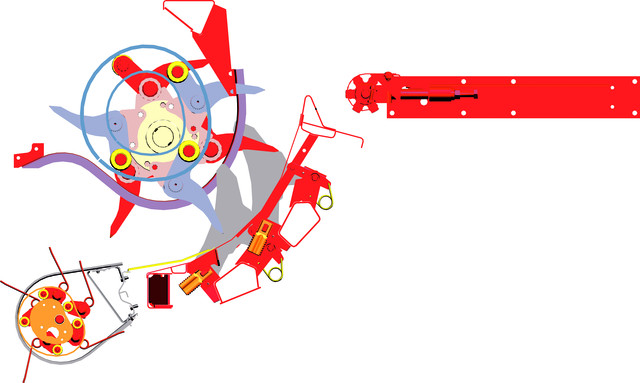

Individual knife protection

How it works

Knife protection

Between the pick-up and the conveyor unit, small foreign objects can fall through the transfer plates.

Larger foreign objects are pressed against the knives for a short time before the trip roller is released out of its detent.

The resistance of the knife is suddenly reduced, which in turn protects the cutting edge.

After the object has passed through the chopping system, a spring pivots the knife back into its original position.

The trigger pressure does not depend on the size and point of contact of the foreign body.

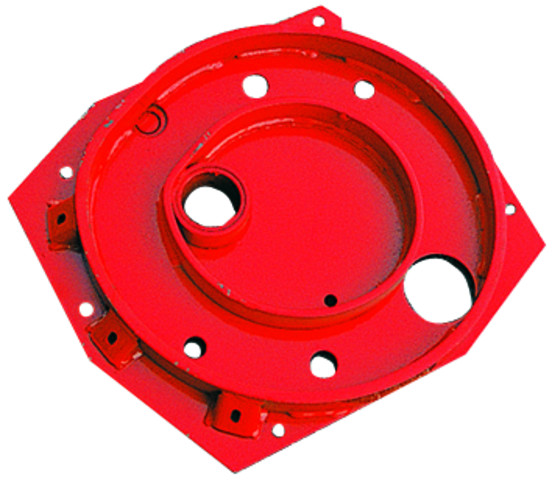

Short chop for high yield forage

The twin-row knife bank is fitted with 16 knives in the top row and 15 knives in the lower row. Thanks to the double row configuration the power requirement is distributed for a smooth chopping action.

A precise and consistent chop is the basis for the best silage quality. The unique solution from PÖTTINGER: the knife bank swings out to enable rapid knife changes. Foreign bodies are a danger to the most important element of the machine – the chopping system. PÖTTINGER protects the heart of the silage wagon with an innovative device – the patented foreign object protection system. Each knife is individually protected.

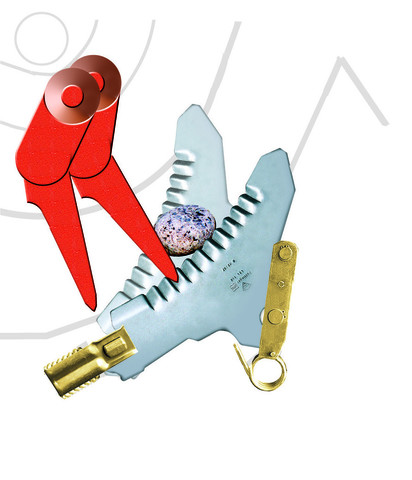

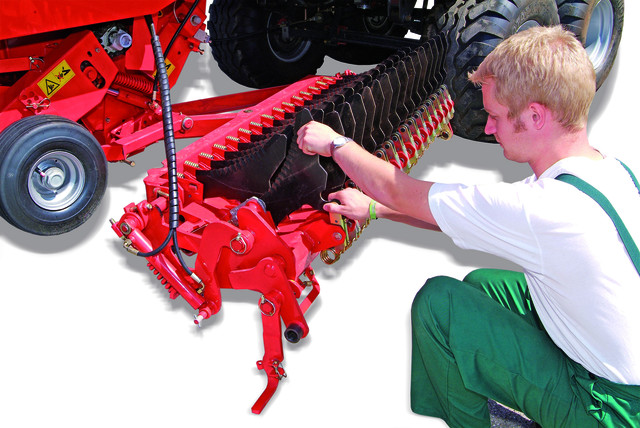

Knife maintenance made easy

EASY MOVE

A hydraulic knife bank pivot system and the unique EASY MOVE system for swinging-out the knife bank is available as an option. There isn't a more convenient way to change knives.

EASY MOVE – it's just so simple

Undo the interlock pins and swing-out the bank to the side.

Disengage the spring-loaded lever to remove and replace the knife.