Loading chamber

×

Unload according to demand on the EUROPROFI D COMBILINE

A uniformly distributed blanket of forage is essential for perfect compaction. Two beater rotors guarantee perfect distribution. The aggressive tines deliver an impressive performance, even with highly compressed forage. Bars on the rotors also ensure maize material can be unloaded effectively. A pressure sensor in the beater rotor bearings controls the scraper floor automatically.

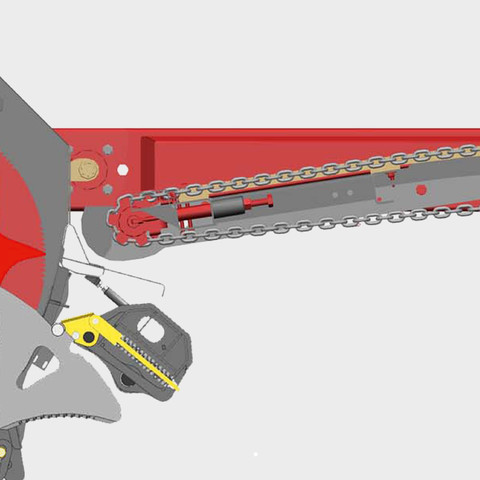

Beater rotor driveline

The driveline to the beater rotors is concealed within the frame. The strong drive shaft is protected by a cam-type clutch at 1,200 Nm.

Multifunction tailgate

The loader wagon is equipped with unloading beaters and a multifunction tailgate.

Tailgate

Normal discharge

Tailgate wide open. The adjustable flow control board swings upwards when the tailgate opens to prevent forage loss.

Fine distribution

Controlled unloading rate to minimise the affect of cross-winds.

Cross conveyor belt mode

Precision feed placement inside sheds without losses.

Cross conveyor belt

For depositing the daily forage ration inside the cattle shed there is a high output cross conveyor belt with a width of 890 mm. This is available as an option on all EUROPROFI D models.

The direction of the belt can be controlled from the terminal

Hydraulic powered

Tailgate locking system with tailgate open

Lowered scraper floor

The scraper floor has been lowered by 150 mm at the front end. As a result, the forage is pushed upwards as it moves to the rear. This ensures smooth, hassle-free unloading as well as a low power requirement.

four powerful drive chains ensure rapid unloading. The tempered slats are separated and offset.

The load chamber floor is constructed of pressure–impregnated, durable wood. This has excellent gliding properties for all types of crop.

Scraper floor drive system

The powerful hydraulic motor is located on the side of the wagon and delivers a reliable output. The speed of the motor is infinitely-variable controlled.

A two-speed motor is available as an option for driving the scraper floor.

An infinitely-variable motor for unloading speeds of up to 16 m/min. is standard

A two-speed motor is available as an option for unloading speeds of up to 20 m/min (standard on the EUROPROFI 5510)

Scraper floor

Scraper floor drive system

Automatic unloading

The automatic unloading system makes life a great deal easier for the driver and protects the machine.

It controls the tailgate, scraper floor and, on the D model, also the beaters. The unloading process can be stopped and started again whenever needed.