Frame and driveline

×

The MULTITAST effect – for trailed large working width tedders

On our high-output trailed tedders, the large wheels on the chassis are on the same axis as the tines' arc of forage contact. They support the machine in the working position and have the same function as the rotor jockey wheels during tedding work. At PÖTTINGER, we refer to this as the MULTITAST effect.

Thanks to the interaction of the chassis wheels and the rotors, you are guaranteed smooth running of the rotors and perfect tedding quality even at higher driving speeds.

Optimum weight distribution

Another advantage of this design is the optimal weight distribution. The frame and chassis do not put any load on the rotors As a result the weight is evenly distributed to all rotor wheels.

Convenient rotor height adjustment

The correct rotor height conserves your soil and keeps the forage clean.

An easily accessible hand crank provides quick, central height adjustment.

For maximum operating convenience, this can also be done hydraulically from the tractor seat as an option. An clearly visible scale shows the set working height.

Straightforward operation

On models with hydraulic rotor height adjustment, the BASIC CONTROL electric pre-select system is standard. With this you can pre-select folding into the transport position, height adjustment and fenceline tedding. Only one double-acting spool valve is needed to operate machine.

Robust frame construction

The robust frame construction of thick-walled, bolted tube profiles makes HIT tedders extremely resilient and durable.

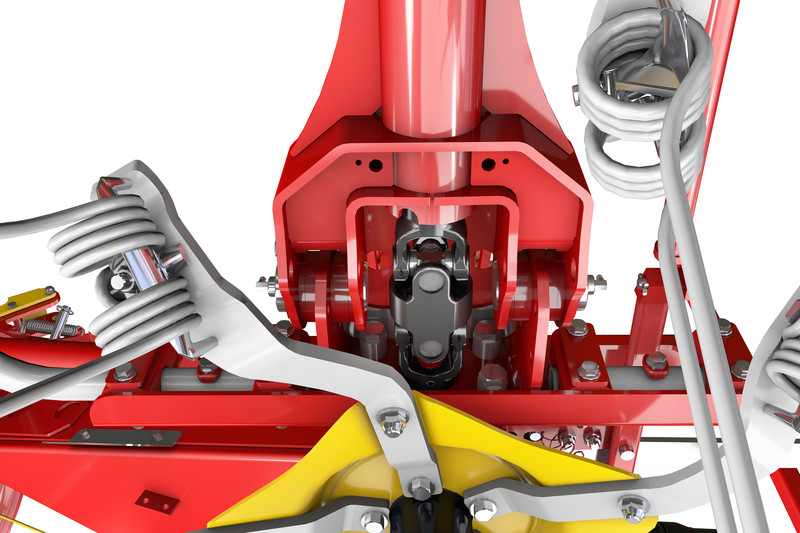

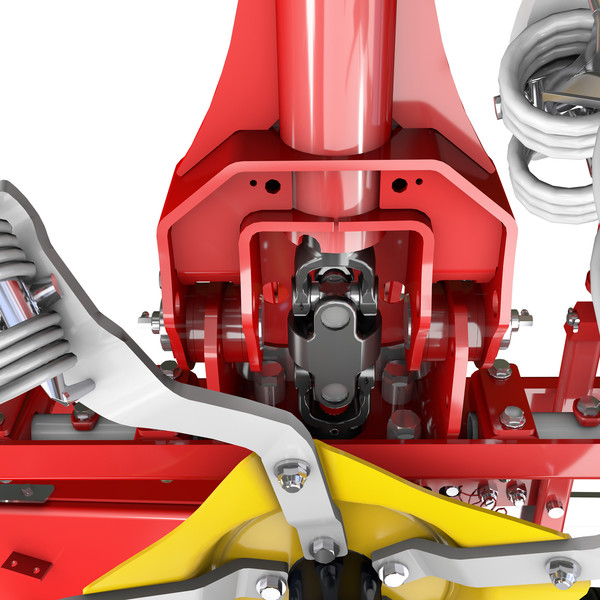

Double sided frame hinges

260 mm wide double-sided frame hinges with 50 mm thick pins provide maximum freedom of movement combined with the highest strength. They are equipped with bushings and are easy to grease - for a long service life.

Rugged construction for long service life

As a structural element, the front guard rail also increases the strength of the tedder. The lattice design stiffens the bolted tube profiles on the main frame, increasing the load capacity and service life of the entire machine.

Backlash free drive joints

The drive train of our HIT tedders is equipped with sealed single and double constant velocity joints. These ensure consistent, smooth, backlash free drive to the rotors. Even with large working widths, there is no backlash from the innermost to the outermost rotor. This ensures that the tines pick up the crop precisely and produce an even spread.

On our tedders with eight or more rotors, positive-locking finger couplings are only installed for the 180 ° folding sections.

All joints can be rotated in any position. This eliminates the risk of operator errors.

Rugged rotor gearbox units

The bevel gearboxes feature large gears and bearings. The closed angular gearboxes are equipped with a greasing system. Oil loss is therefore not possible.