Durable

×Our HIT V ALPIN tedders are real lightweights. But despite the low weight of these machines, PÖTTINGER places great emphasis on durability.

The pressed profile frame and spring steel tine carriers reduce weight while guaranteeing maximum strength. The rotor dishes are made of high strength components with precise placement for the tine arms. In addition, the tine arms are also bolted to the rotor hubs to ensure an extremely secure mounting.

The drive train on our HIT V ALPIN tedders is equipped with sealed constant velocity joints. These ensure consistent, smooth, backlash free drive to the rotors. There is zero backlash from the innermost to the outermost rotor.

All joints can be rotated in any position. This eliminates the risk of operator errors.

The bevel gearboxes feature large gears and bearings. The closed angular gearboxes are equipped with a greasing system. Oil loss is therefore not possible.

Machines that retain their value

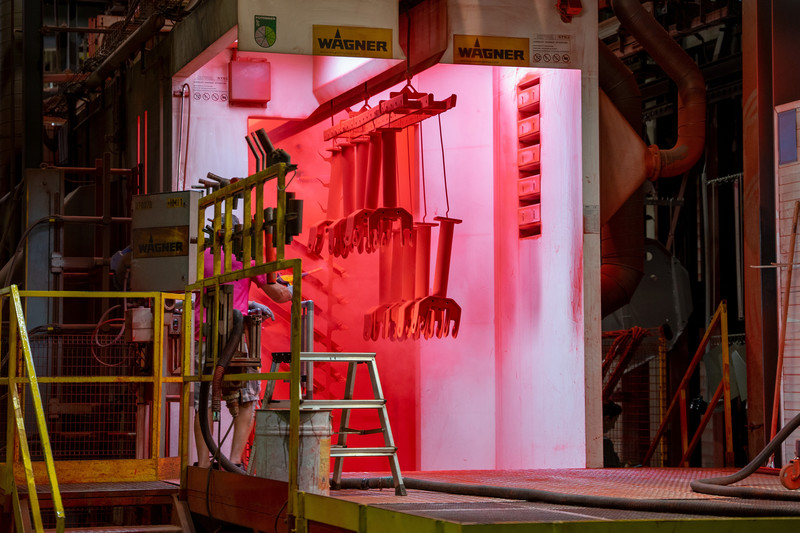

High quality cathodic dip priming and powder coating guarantee elasticity and durability. Featuring eye-catching colours and a modern design, you are sure to enjoy working with these machines that retain their value.

Put through its paces

In addition to field trials, the machines are tested in our Technology and Innovation Centre (TIZ) for quality and suitability in operating conditions that mimic those in the field. This is where research, development and application come face to face.