Convenience and maintenance

×

More convenience

Harvesting can mean a long day in the field, so it is all the more important to make your work with the loader wagon as smooth and enjoyable as possible. The practical automatic solutions on the JUMBO go a long way to helping you achieve this.

When the harvesting day begins with sharpened knives it may be advisable to sharpen the loader wagon’s knives after only 2–4 hours. With AUTOCUT you always have a fully automated knife sharpening system at your fingertips. This guarantees you perfect chopping quality for as long as the working day lasts. When evening comes there is no need to remove the knives to sharpen them. AUTOCUT saves you an enormous amount of time.

Numerous automated functions support you in every operating situation. Pick-up position along with speed control, automatic transport and loading position, loading torque measurement, the intelligent front panel with loading and unloading strategies or the automatic unloading system all make life more convenient for you the driver.

This ensures you are operating in a relaxed environment whilst getting the most out of your machine.

Less servicing

During development of the third JUMBO generation the topic of maintenance was very much in the spotlight.

Number of gearboxes on board has been halved

The front sprockets run on sealed bearings

Rear scraper floor shaft bearings with central greasing points at the side

Service life at specific wear points such as the pick-up tines, the loading rotor, the knife steel quality, the chopping unit rear wall and the scraper floor has been increased considerably.

Powerful sensor technology

The additional functions are made possible by the installation of sensors that measure position, speed and power.

An angle sensor for detecting the position of the pick-up and a speed sensor to control the hydraulic pick-up driveline help to harvest the forage conveniently and easily. A dynamometer bolt on the belt drive and the intelligent front panel support automated control of loading.

Service counter

The driver is informed of forthcoming service intervals by a display on the control terminal. If the service counter has expired, the Service data screen is displayed first next time you start the machine. This lets you easily keep track of upcoming service work.

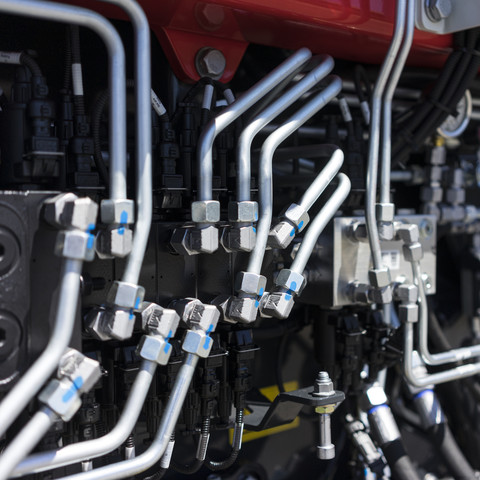

Hydraulics concept

Thanks to the separation of hydraulics and electrics the loader wagon can be cleaned more easily and effectively. The cables are arranged clearly, making it easier to detect faults and reduce downtimes.

Our farm works well when our drivers are happy

"The new JUMBO is operated predominantly by a driver who has years of experience, and he always says: "This machine is really phenomenal." So he is enormously enthusiastic about it.

Previously he drove a JUMBO 6610 and 6620 and says: "The new JUMBO takes another big step forward - both in performance as well as ease of operation. We used the movable front panel to shift more weight onto the tractor on steep terrain." The new front panel also makes the loader wagon quick and easy to unload, which impresses all our drivers and our customers.

The automatic loading function works brilliantly too!"

Roland Kobler, Contractor | Agrolohn GmbH, Passau , Germany