Belt drive

×

Power transfer reinvented

The innovative, unique drive concept has been designed for tractors rated from 200 to 500 Hp. This means that the JUMBO can be operated with a wide range of tractors.

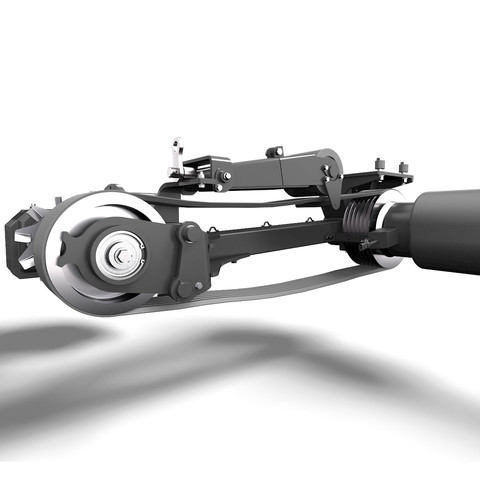

The driveline has a double wide-angle PTO shaft without a clutch and is powered by a Powerband. Optimum power transmission to the rotor is ensured by angular/planetary gears in the rotor drive.

The Powerband delivers maximum power transfer in all operating conditions. It ensures smooth running and a damping effect in changing operating conditions. This protects the mechanics and reduces maintenance and wear costs to a minimum.

Special overload protection system

A PTO shaft with an overload protection system is subjected to extreme wear-intensive stress when used in high-performance harvesting equipment. The angle of the PTO shaft during operation produces torsional vibrations which prematurely trigger the overload protection system and negatively impact throughput.

PÖTTINGER therefore decided to remove the overload protection from the PTO shaft and integrate it directly in a fixed position in front of the angular/planetary gearbox.

Thanks to the newly developed drive concept the JUMBO can be continually operated at up to 3000 Nm. The result is optimum protection of all drive components against unnecessary stress and wear-intensive blockages.

Irregular swaths can be picked up with no reduction in speed and no losses, even when cornering. This increases loading efficiency enormously.

Perfectly matched

In order to be able to optimise the JUMBO to the forage and the tractor power, a dynamometer bolt constantly monitors the torque applied to the drive train.

When this reaches the set maximum value, the scraper floor is activated. That is how the compaction of the forage by the rotor can be optimally adapted to the incoming forage volume and the power of the tractor.

Powerband

The 6-groove high-performance belt has been designed for extra long life and guarantees reliable power transmission. It can cope with the toughest demands and also ensures smooth running in all operating conditions. Operating noise is reduced to a minimum.

The belt’s damping effect in changing swath conditions benefits loading performance.

The Powerband is maintenance-free.

Soft start

Thanks to its soft start, the drive belt enables operation of the rotor and rear beaters even under full load. There is consequently no need to advance the scraper floor when unloading with beater rotors. The scraper floor chains and drivelines are protected, which significantly increases both reliability and the service life of all components.

The drive belt on the JUMBO makes a conventional clutch system unnecessary.

PTO shaft without overload clutch

The innovative design of the drive belt means that no overload clutch is needed on the PTO shaft.

Conventional systems lose as much as 20 % of torque owing to angling and the resultant vibrations, especially when cornering.

The JUMBO is therefore able to draw on the full torque of 3000 Nm pm the 7000 series and 3500 Nm on the 8000 series, whatever the operating conditions.