Rotor

×

It simply moves more

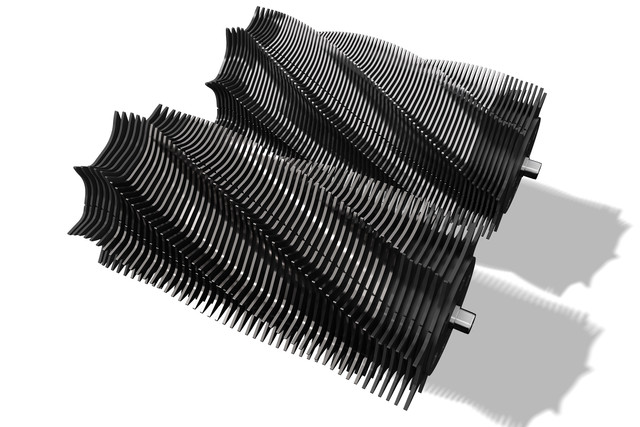

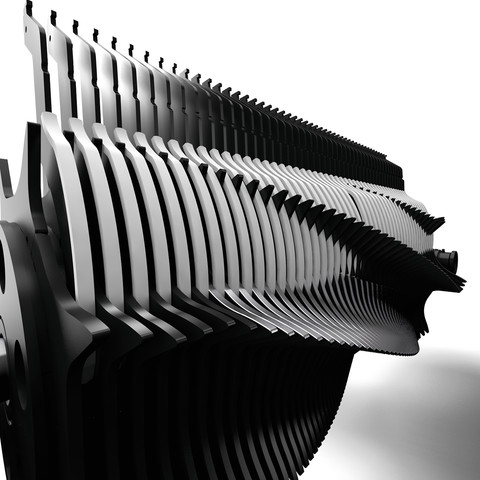

The heart of the JUMBO series is robust, powerful and designed for almost unlimited tractor power. The rotor and its innovative driveline provide high throughput, perfect chopping quality and, if required, the highest possible compaction.

Thanks to the wide, edged areas at the 12 or 10 mm tine tips on the 8-row rotor, it takes over the crop actively and reliably from the pick-up, even if the crop is wet and short. The rotor tines are arranged in a helix formation, with a diameter of 850 mm to guide the forage smoothly through the 34 or 25 mm short-chop knife bank. The rotor is mounted directly on the chopping system frame in order to protect the rotor drive as much as possible even under heavy load.

A tine form that has been optimised still further, combined with the largest possible scraper surface in the loading chamber, makes compaction of over 400 kg/m³ possible if required.

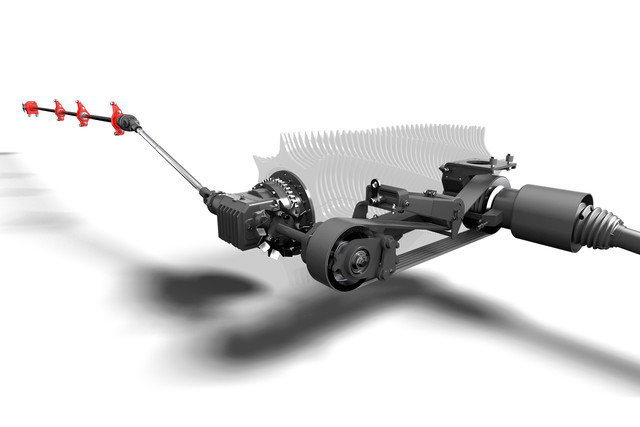

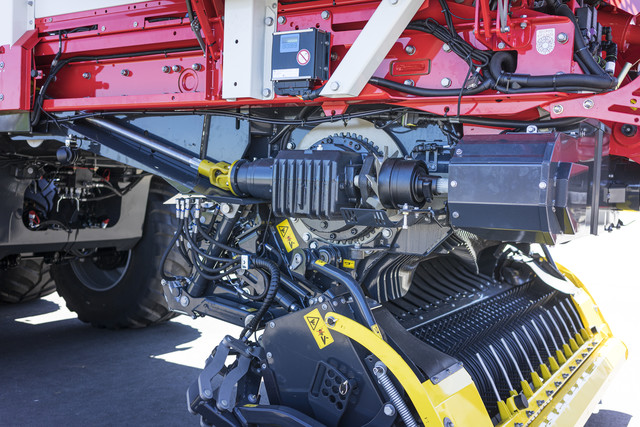

Driveline

The rotor is powered by angular/planetary gears which lower the high PTO speed to the ideal rotor speed. On the JUMBO range with beater driveline, the forward-mounted angular gearbox also features a through shaft and an integrated switch.

When the beater driveline is activated, the maintenance-free clutch engages, the drive belt starts softy and unloading begins.

The components are protected and a long service life guaranteed.

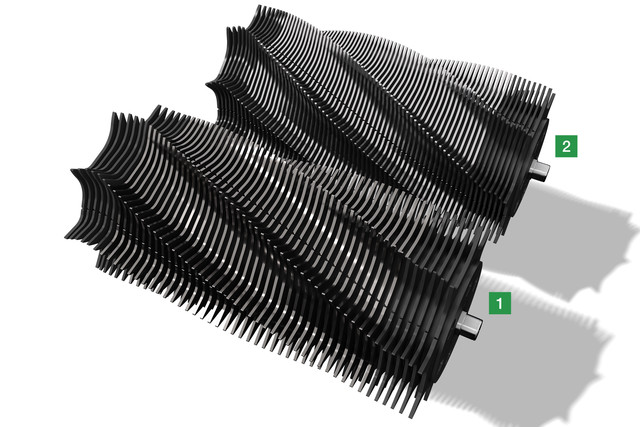

Loading rotor

75 % of the rotor’s width is fitted with a new high-strength case-hardened steel which ensures high wear resistance in areas subjected to a lot of wear. This increases service life by 25 %.

1 Rotor on the JUMBO 7000 series

2 Rotor on the JUMBO 8000 series

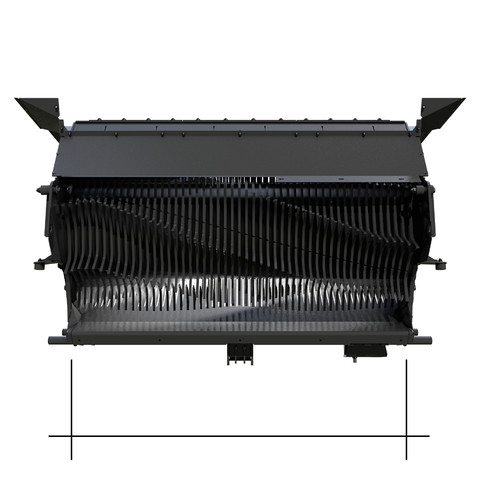

Scrapers

Each of the scrapers in the loading chamber has a wide backing. The large scraper surface ensures best possible crop retention in the loading chamber. The crop is cleanly scraped off the rotor and is not drawn in:

This allows a high degree of compaction in the loading chamber if need be, which increases the cost effectiveness even when field to farm distances are long.

The scrapers are made of wear-resistant Hardox which gives you the longest possible service life.

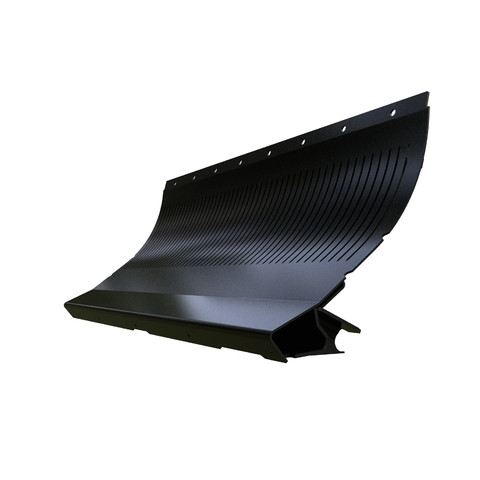

Transfer throat

The transfer throat has been widened by 100 mm, thereby allowing even greater throughput than its predecessor. It guarantees a high level of efficiency during chopping and allows shorter chopped length at edge than other, wider commercially available loading systems.

Chopping unit rear wall

The chopping unit rear wall on the JUMBO consists of wear-resistant fine-grained steel. This greatly increases the service life.