COLLECTOR

×

Swath merging with a conditioner

With the COLLECTOR you can mow, condition and swath in just one pass. You save time and money and reduce your weather risk.

Mowers equipped with the COLLECTOR offer flexible swath merging with the conditioner and cross conveyor belts. This proven system stands out especially for its loose and airy swath placement.

The COLLECTOR is available for the NOVACAT V 10000 ED / RC.

Perfect ground tracking despite higher weight

Thanks to the hydraulic weight alleviation of the mower units on the NOVACAT V 10000, the pressure the cutter bar exerts on the ground can be easily adjusted. This ensures excellent ground tracking despite the higher weight due to the belt unit.

Maximum output

Even with large volumes of forage, your mower works reliably thanks to the large conditioner hood and the 980 mm wide belt. You are guaranteed neat swath placement at maximum output.

Driveline

On the NOVACAT V 10000 the cross conveyor belts are driven by the tractor’s hydraulics.

With the standard SELECT unit, the operating speed can be set using the oil flowrate function on the tractor remote and adjusted using the control terminal.

On machines with the Profiline comfort control system, oil is supplied via the load sensing system. You can adjust the speed electronically using the control terminal. An automatic mode can also be activated to control this.

Optional accelerator rollers ensure particularly narrow swath placement.

Convenience

With the COLLECTOR system, the crop can be placed as a wide blanket, in a swath, or wide-spread to one side.

For maximum convenience, you can pivot the two cross conveyor belts up and down as standard from the tractor seat.

Easy to remove

It only takes a few minutes to remove the conveyor belts and park them on an optional chassis.

You have the choice when it comes to swath placement. Depending on your requirements, you can pivot the two cross conveyor belts up and down hydraulically conveniently from the tractor seat.

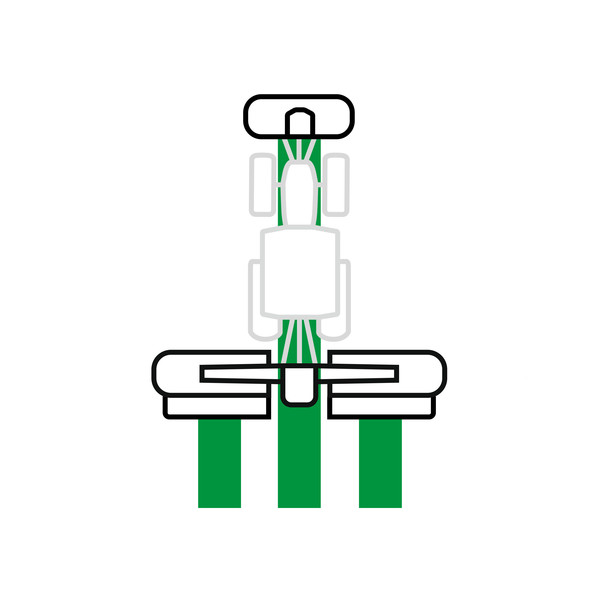

Individual swaths

Raising the cross conveyor belts and narrowing the swath doors places three compact individual swaths.

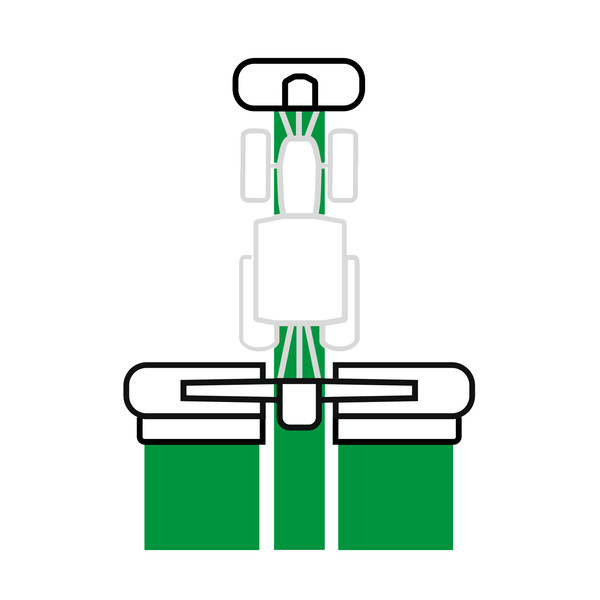

Wide spread placement

With the swath doors open, guide plates direct the flow of forage across the whole mown width. The forage is deposited in a uniform and airy blanket.

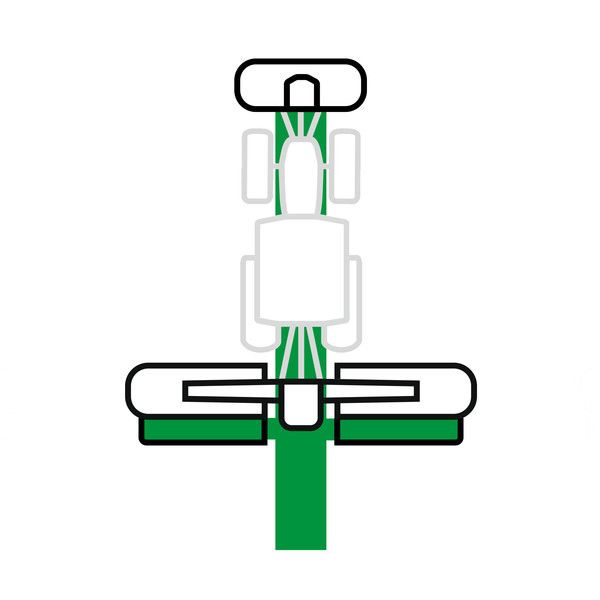

Three swaths in one

The conveyor belts place the three swaths into one large central swath.

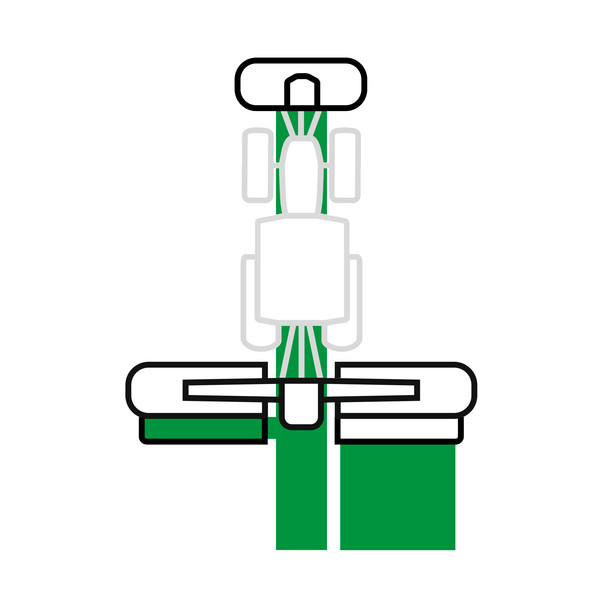

Intelligent swath placement

With the conveyor belts lifted individually, up to 40 % raking work can be saved with a large TOP rake. That is how you save time and money.

Optimum swath placement

A mechanically height-adjustable acceleration roller is available as an option for the NOVACAT V 10000 ED / RC. This lets you adjust the swath width. Compact swaths formed by running both COLLECTOR belts to one side are possible with the optional swath rake.