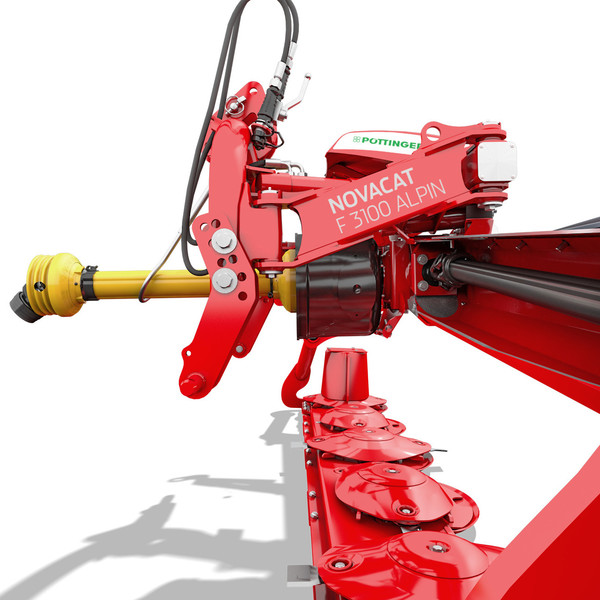

Driveline

×

Robust drive train

The friction-locked driveline is protected within the frame. It guarantees reliable power transmission and is able to handle ever-increasing tractor power. It can be easily greased through maintenance ports.

As you would expect from our NOVACAT disc mowers, the driveline passes down the axis of the first drum. A maintenance-free constant velocity joint ensures a stress-free connection.

The driveline for every application

The input gearbox is available as 540 and 1000 rpm versions. By turning the gearbox over, left or right rotation is possible.

Overload protection is integrated into the input PTO shaft. The freewheel is located in the side gearbox.

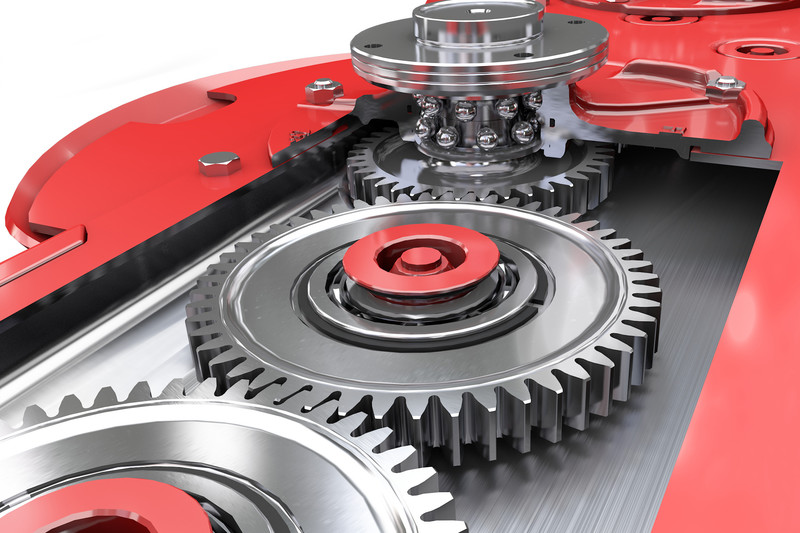

TRI DRIVE concept

The spur gear driveline runs in a straight path inside the cutter bar with virtually the same sized gears. On the gears there are always three teeth in contact with each other – this ensures optimum power transmission. Moreover, there is less stress on the individual gears in the event of stone impact.

The specially ground surface of the gears submerged in gear oil ensures smooth running. This reduces the noise level considerably.

The gears are arranged as standard so that the mower discs rotate towards the centre.

Heavy-duty bearings

The stub shafts of the individual mower drums have heavy-duty bearings. Durable, twin race taper bearings with a bearing spacing of 60 mm are extremely stress-resistant. Shock loads are absorbed effortlessly.

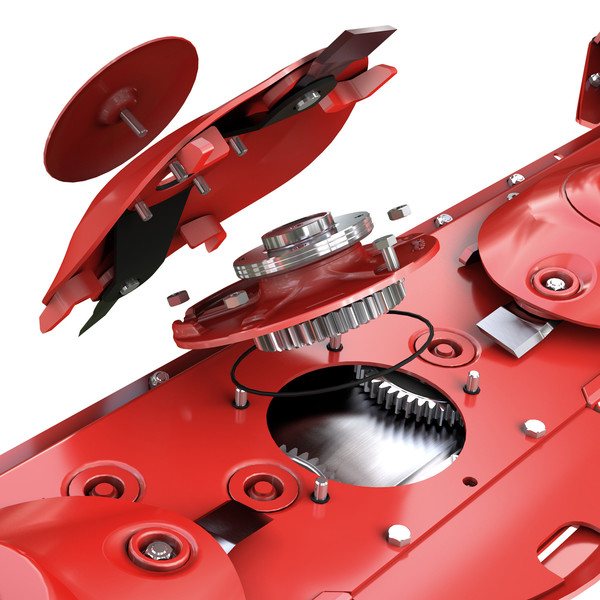

Bolted stub shafts

The high-strength stub shafts are bolted to the gears. Each of the parts can easily be replaced if required.

Shaft stub

Taper bearing

Bearing flange

Spur pinion

Practical modular design

Bevel gears and bearings can be removed as a single unit The idler gears are also easily removed through the openings - it couldn't be easier!

The bearing flange and fittings are reliably protected by rubber o-ring seals. This prevents dirt or dust from entering the gearbox. It also avoids oil leakage.