Rear rollers

×

Wide choice of rear rollers

In addition to precise depth control, the rear roller is also responsible for achieving the necessary consolidation. This is essential for optimising the germination conditions for volunteers and weeds, and also to prevent the soil from drying out, especially in the summer months. The soil is further crumbled and levelled by the roller. It also has a positive influence on the surface structure of the soil. Different soils and soil types have their own specific characteristics. That is why PÖTTINGER offers a wide range of rear rollers, depending on the soil, application and the objective of the tillage pass. It's your choice.

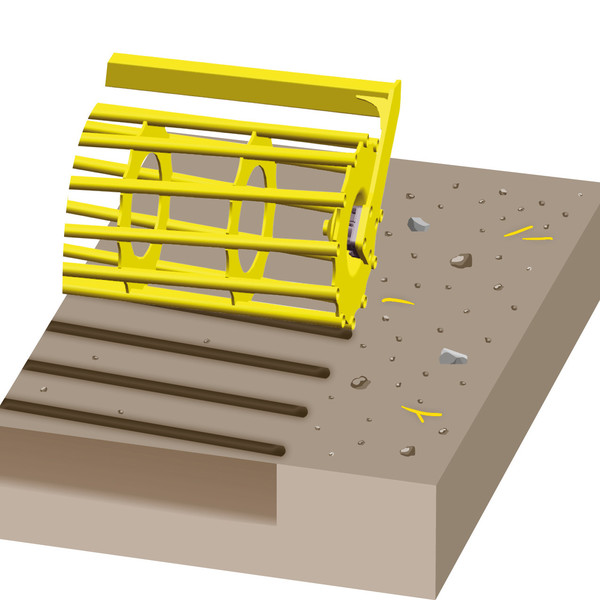

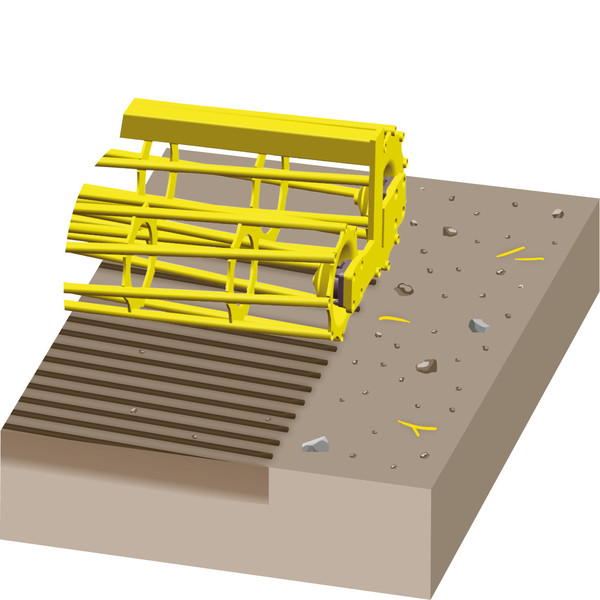

Cage roller

The cage roller is ideal for dealing with dry, non-sticky soils. The strong bars consolidate the soil across the direction of travel, making sure that the roller keeps rotating, while creating a high proportion of fine soil. With a diameter of 660 mm, the cage roller is equipped with twelve horizontal bars that provide the necessary self-propulsion.

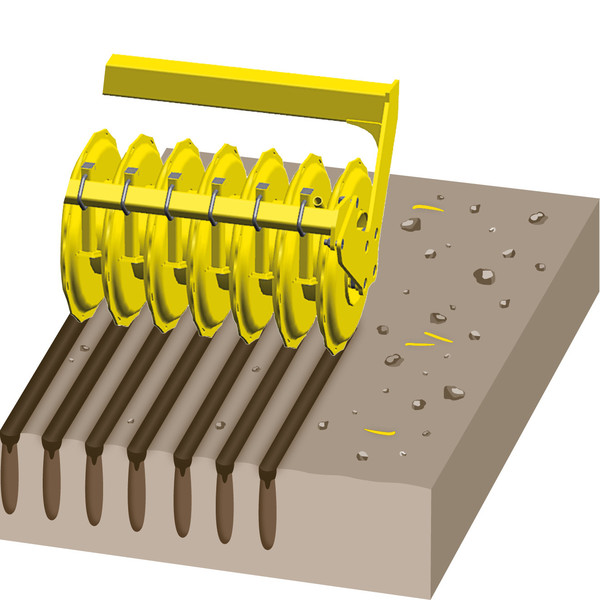

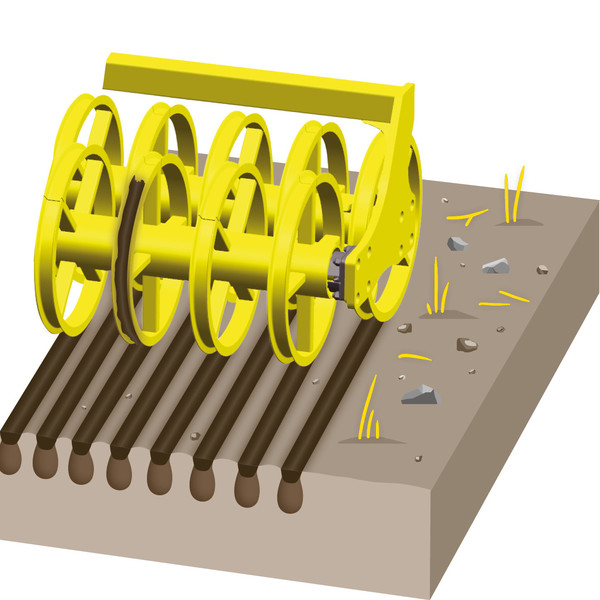

CONOROLL roller

Four individually bolted segments form a 540 mm diameter ring. The segments are conical and offset to the left and right. This produces consolidated ridges with alternating indentations to the left and right of each groove. Rainwater can seep into these indentations so that it is prevented from running off the surface. In addition, the loose soil between the rings can absorb water better. The optimised structure on the soil surface prevents erosion caused by rain. Spring-loaded scrapers are mounted between the rings, and these also produce a fine tilth thanks to their conical shape.

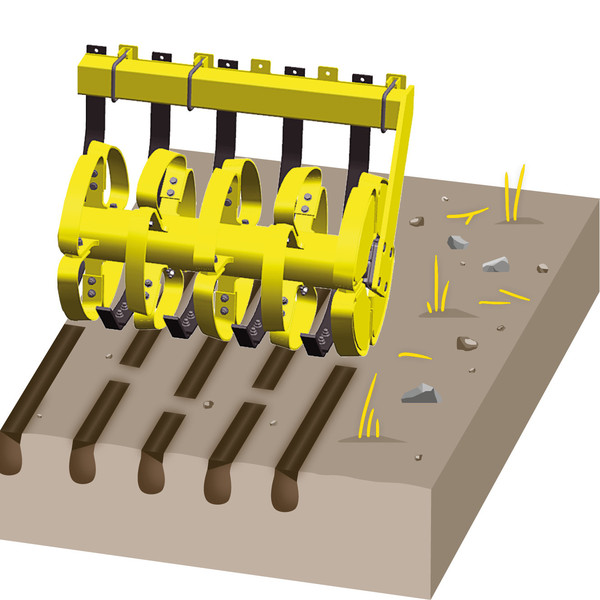

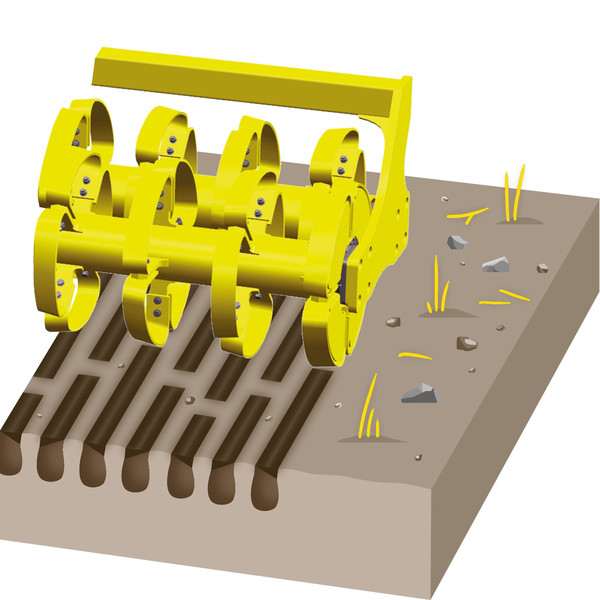

Pack ring roller

The pack ring roller consists of eight pack rings with solid rims per metre of working width. The roller produces consolidated ridges to promote drainage and let the soil breathe. The roller achieves solid working results even on stony or damp soil with high volumes of organic material. In dry conditions, the deep consolidation has a positive effect on seed germination conditions. The coated scrapers mounted between the rings ensure the roller keeps rotating even on sticky soil.

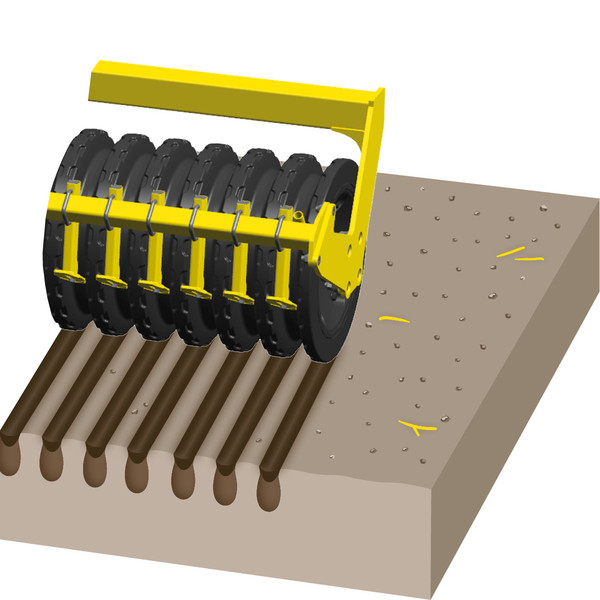

Rubber packer roller

The rubber packer roller is a versatile implement that is able to handle a wide assortment of highly variable soils. The profile of the roller produces consolidated ridges and has a large area of contact with the soil. The roller has a diameter of 590 mm and offers a high load-bearing capacity. The scrapers are coated and ensure neat and tidy operation.

Double cage roller

The double cage roller consists of two rollers with different diameters. The front cage roller has a diameter of 540 mm, while the rear roller is 420 mm. The two rollers are mounted on floating suspension for optimum ground tracking. The second roller increases the crumbling effect and the proportion of fine soil. It also increases the load-bearing capacity thanks to the larger ground contact area.

Tandem CONOROLL roller

Like the single CONOROLL roller, each ring on the tandem CONOROLL roller consists of four segments, two angled to the left and two angled to the right. Each segment creates an indentation in which rainwater can seep into the soil before it runs off the surface. Both rollers have a diameter of 560 mm. With a ring width of 70 mm, the tandem roller configuration offers an impressive load-bearing capacity, especially on lighter soils, and has good self-cleaning properties. The freedom of movement and the angle of the rear roller can be adjusted to match the operating conditions for optimum ground tracking.

Tandem U profile roller

The U-profiles on each ring with a diameter of 600 mm fill with soil during operation. This results in direct earth-to-earth contact, ensuring well-formed consolidated ridges, while conserving the soil structure. In addition, it achieves good self-propulsion and the adhering layer of soil reduces wear. The tandem rear roller configuration guarantees a high load capacity, making this tandem U-profile roller equally suitable for fields with light soil types. The angle of the rear roller can be adjusted to match different operating conditions.

Levelling board

When fitted with the tandem CONOROLL roller or the tandem U-profile roller, the PLANO can also be equipped with a levelling board between the last row of tines and the roller. The spring-mounted drag tines with replaceable wear plates level and crumble the soil. Depth control is always synchronised with the rear roller. The work intensity is adjusted mechanically.

Requirements | Cage roller | Double cage roller | Pack ring roller | Rubber packer roller | CONOROLL roller | Tandem CONOROLL roller | Tandem U profile roller |

Consolidation | o | o | + + | + + | + | + + | + + |

Damp conditions | o | o | + + | + | + + | + | + |

Dry conditions | ++ | + + | + + | + + | + + | + + | + + |

Crumbling effect | + | + + | + + | + + | + + | + + | + |

Load capacity | + | + + | + + | + + | + | + + | + + |

Self-propulsion | + + | + + | + + | + | + | + + | + |

Applicability for stones | + | o | ++ | o | + + | + + | + |

Scrapers | No | No | yes | yes | yes | no | no |

Tare weight for 6 m working width | 650 kg | 1.04 kg | 1.19 kg | 1.12 kg | 860 kg | 1.37 kg | 1.3 kg |

Diameter in mm | 660 mm | 540 / 420 mm | 550 mm | 590 mm | 540 mm | 560 mm | 600 mm |

++ highly suitable

+ very suitable

o suitable

- not suitable