Beater rotors

×

BOSS DB

PÖTTINGER offers two models with discharge beaters (DB) for unloading in the clamp or depositing forage with the cross conveyor belt.

The smaller model with a load volume of 21.3 m³ can be equipped with a single axle, which makes it particularly light and agile. The larger model with a capacity of 23.9 m³ is equipped with the tandem chassis for heavy silage work.

Both models have two beater rotors as standard, with a third available as an option. A side access door with ladder is standard equipment.

Due to the wide range of applications covered by the DB models, they are equipped with the Comfort control terminal as standard.

Removing the beaters

The beater rotors can be easily removed. As a result the wagon can be quickly converted for harvesting unchopped crops such as hay or straw. So a DB model still gives you total flexibility.

Three beater rotors

An optional third beater rotor improves the unloading process even further. It ensures that the full height of the crop inside the loading chamber is loosened and discharged uniformly into the clamp. Redistribution of the forage is usually not required. That saves time.

When the dry forage extension is folded down, the third beater rotor also folds down.

An additional rear tarpaulin is supplied together with the third beater rotor. This ensures even more precise unloading and prevents forage residues from accumulating at the rear of the wagon.

It is recommended for use with the cross conveyor belt.

Cross conveyor belt

With a depth of 600 mm, the cross conveyor is designed for fast unloading of the loader wagon. While the cross conveyor belt is not in use, it can simply be pushed in under the scraper floor. The direction of the conveyor belt can be changed simply by repositioning the drive shaft.

The purely mechanical drive of the cross conveyor belt, makes no special demands the tractor's hydraulic system.

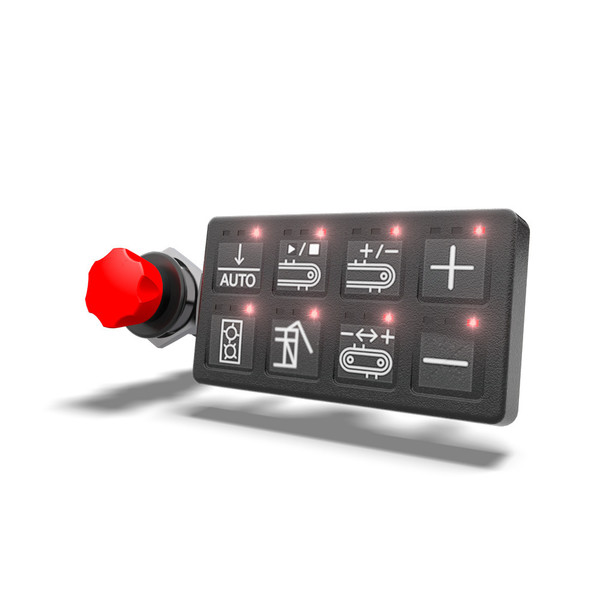

Rear-mounted controls

For working with a forage blower and unloading using the cross conveyor, the optional rear-mounted controls are recommended. A keypad mounted on the tailgate lets you conveniently control the unloading process. In addition to activating the scraper floor, you can also control the scraper floor speed or disengage the beater rotor drive system. With the controls mounted on the tailgate, you have a perfect view of the unloading progress regardless of to which side the wagon is being unloaded.