Pick-up

×

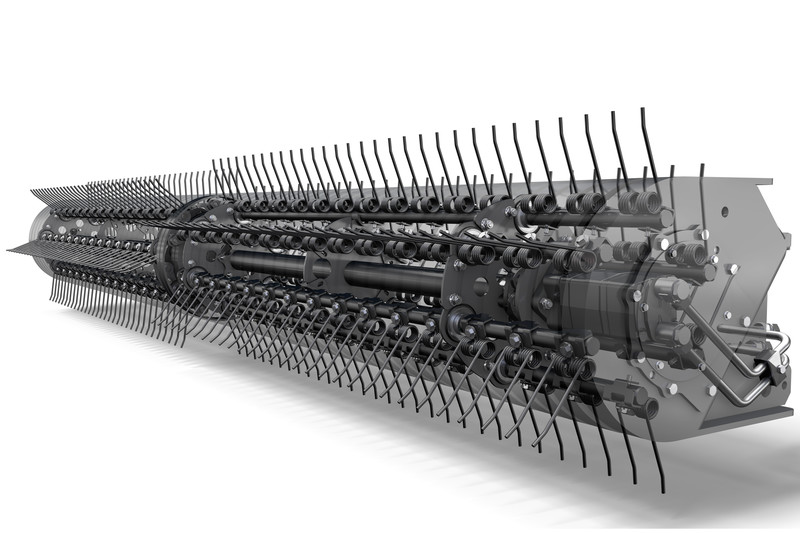

Controlled pick-up

The six-row controlled PÖTTINGER pick-up ensures maximum crop intake performance with minimum forage contamination.

The crop is gently collected from the ground by the controlled pick-up tines and accelerated towards the cross conveyor belt. Meanwhile, dirt and stones remain on the ground.

Reliable crop take-up in all operating conditions

The cam track control system guarantees maximum pick-up capacity at high driving speeds. Reliable crop take-up is also ensured when driving downhill.

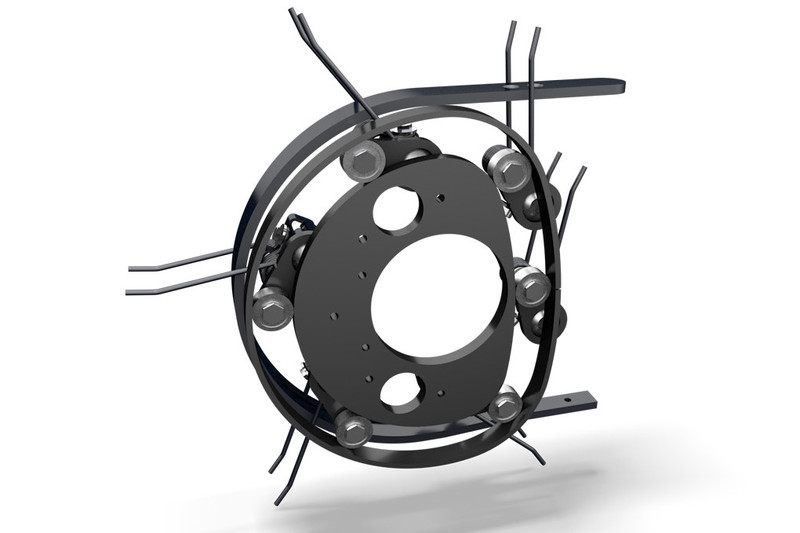

Two-section construction

The pick-up on each belt unit is divided into two parts. The tines of the two halves of the pick-up are each controlled by a cam track. The two cam tracks are at the centre of the pick-up. Towards the outside, the tine carriers are each guided by two support discs.

This innovative design means that the tines reach right up to the very edge of the pick-up. This ensures cleanly collected crop over the entire surface, especially when a side swath is deposited and both belt units are working directly next to each other.

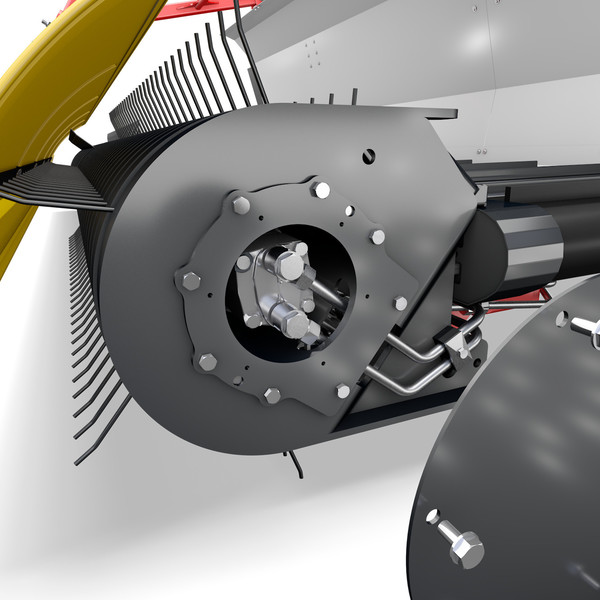

Hydraulic drive

The pick-up on each belt unit is driven by a hydraulic motor. This is easily accessible from the outer end of each pick-up. The speed can be easily adjusted to the travelling speed and operating conditions by adjusting the PTO speed.

Robust cam tracks

The shape of the cam track determines the exact movement of the tines. The control levers with rollers steer the tine carriers and tines along the path. This unit is robustly built and designed for maximum service life.

The entire pick-up was subjected to a life cycle test at our Technology and Innovation Centre (TIZ), which it passed with flying colours.

Gentle crop take-up

The trailing position of the tine near the ground ensures the best contour adaptation without scraping the sward.

In addition, a controlled pick-up is used with a much lower speed than a conventional pick-up. As a result, MERGENTO further minimises disintegration losses.

Angled tines

The tines on the pick-up are angled forward in a dynamic position.

Due to this design, they actively lift the forage away from the ground - like a pitchfork. This guarantees reliable and loss-free crop take-up, even with short forage.

The pick-up can be set with a slightly larger distance to the ground. This not only results in clean forage, but also protects the entire machine and the sward.

Excellent transition to belt

Thanks to the cam track control system, the full length of the tines conveys the crop right up to the cross conveyor belt. The tines dip down at right angles just in front of the belt.

In contrast to an uncontrolled pick-up, the acceleration force is directed towards the cross conveyor belt right until the end. There is no risk of the forage being dragged in past the scrapers at the end.

This guarantees the best under of forage all operating conditions.