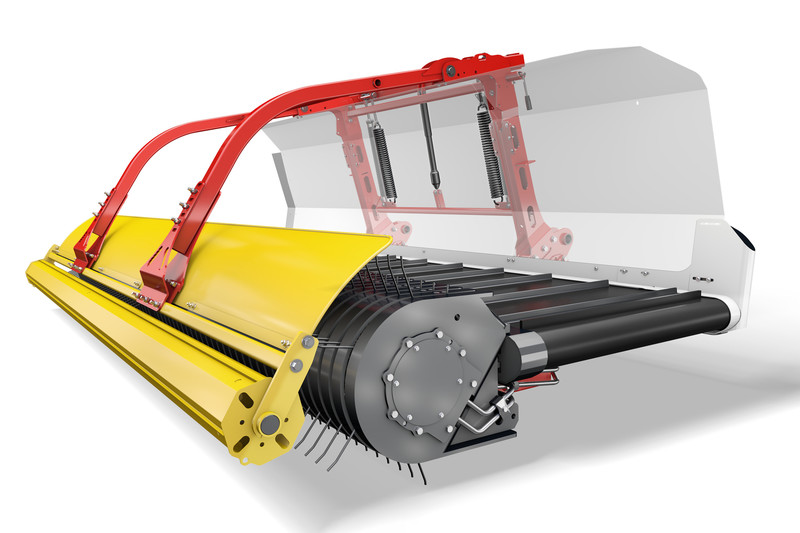

Crop press roller

×

Crop press roller

MERGENTO is a real team player in the harvest chain. It ensures that the follow-up machines also deliver top performance.

How does it do that? Quite simply, by leaving perfectly formed swaths - and in a wide variety of crops.

This requires a continuous flow of forage. Here, in addition to the controlled pick-up, the crop press roller plays a decisive role. It supports the pick-up both when collecting the material and when transporting it further towards the cross conveyor belt.

Reliable crop flow even with short forage

Especially in short forage and permanent grassland, the crop press roller guarantees the merger delivers uniform swath placement.

Adjustable, spring-damped mounting

The crop press roller is spring damped and can optimally adapt to the incoming volume of forage. In the case of large volumes, it simply rides upwards. A gas pressure damper is also installed to prevent abrupt upward movement. The minimum gap between the pick-up and crop press roller can be conveniently adjusted to the crop and your driving speed using a threaded spindle.

Reliable crop take-up

The roller supports the pick-up during crop take-up. It regulates the forage lying on the ground and compresses it slightly to promote a more consistent and higher intake performance of the pick-up. It rotates in the direction of travel and rolls smoothly over the forage.

In addition, possible forage ejection with short crop is prevented, as the rotation of the roller directs the forage in the right direction.

Reliable crop flow

The baffle curtain presses the forage into the pick-up. A channel is created that accelerates the forage towards the cross conveyor belt. The crop achieves sufficient momentum to be spread evenly over the entire depth of the belt, even when driving downhill.

Thanks to the spring-damped suspension, the baffle curtain together with the feed roller can deflect upwards to ride over larger volumes of forage.

Full flexibility

If necessary, the crop press roller can easily be raised, i.e. deactivated, in a few steps.

This can be particularly useful for bulky crops such as hay, straw or alfalfa.