Cross conveyor belt

×

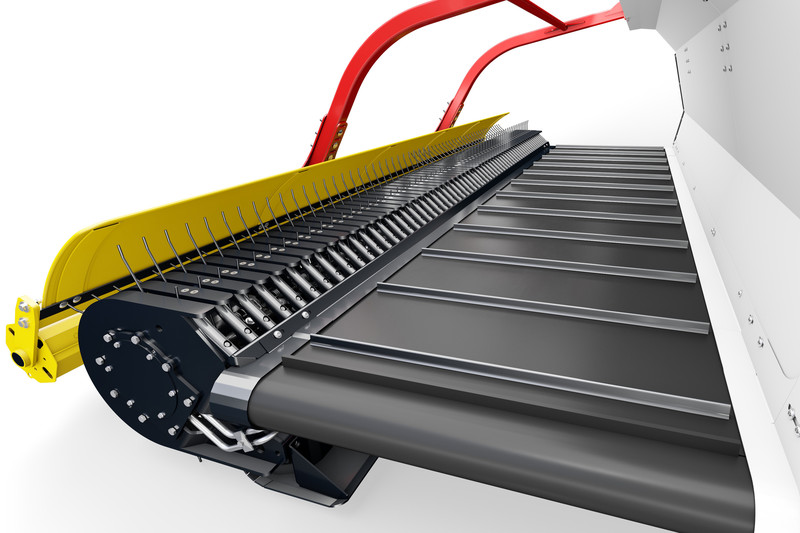

Cross conveyor belts

The two cross conveyor belts are designed for power and strength. The pick-up places crop over the full width of the belts so they can transport the forage sideways to be deposited in a loose swath.

Maximum output

Thanks to the 900 mm high rear wall and the 900 mm deep cross conveyor belts, the MERGENTO works reliably even with high volumes of forage. Crossbars ensure that even bulky crops such as hay or straw are transported reliably to the swath.

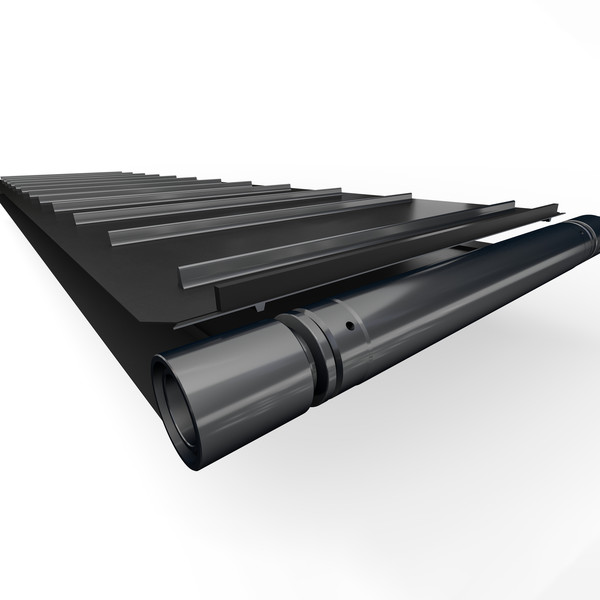

Durable

The cross conveyor belts are designed for maximum service life. The belts are made of a fabric reinforced rubber. The crossbars on the belt surface are vulcanised for a permanent bond. Two longitudinal webs are also vulcanised on the inside. These run in the guide grooves of the belt rollers and prevent the cross conveyor belt from off tracking.

Perfect forage flow

The cross conveyor is positioned 120 mm lower than the pick-up transfer point. The forage virtually falls freely onto the conveyor belt. The following forage pushes the material on the belt towards the rear. This guarantees perfectly shaped swaths and reliable operation both downhill and with short forage material.

Tensioned without the need for tools

The tension of the belts can be adjusted quickly and without tools by rotating the hole matrix disc at the back.

Maintenance-friendly

For easy maintenance and cleaning, the two cross conveyor belts can be unbolted.

A secure bolted connection over the entire belt width guarantees durability as well as making the belt easy to remove when required.

This makes it easy to clean the belt rollers if necessary.