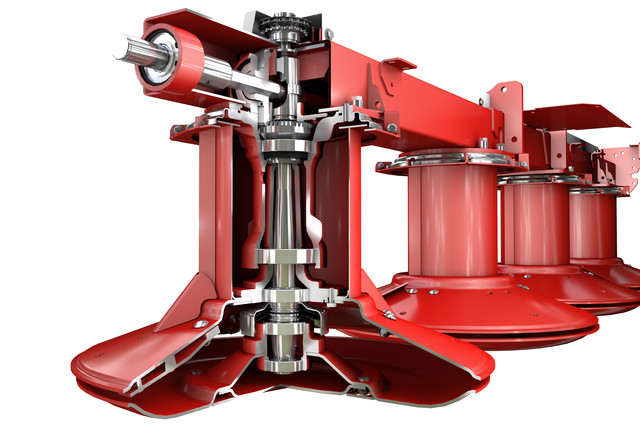

Mower drum

×

Four equally sized mower drums

Four equally sized mower drums guarantee the best working results in all conditions.

Clean and tidy cut:

All four drums have the same blade arc circumference. This guarantees a clean and tidy cutting pattern.

Unrestricted flow:

The large mower drums in the centre allow tremendous clearance. The two central drums also have narrower necks, providing even greater clearance.

Perfect ground tracking:

Each drum is in contact with the ground over the same area. This equal distribution of pressure ensures perfect ground tracking.

Mowers to meet the highest expectations

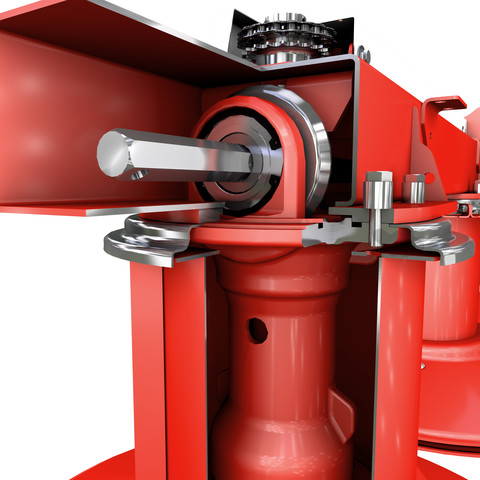

Smooth-running driveline

Two driveshafts and an angular gearbox ensure reliable power transmission. On the front mowers, three V-belts in the driveline protect against overload. The freewheel is integrated into the input gearbox. On our rear mowers, a friction clutch serves as overload protection. The freewheel is located in the side PTO shaft.

Power is transmitted from the hexagonal shaft in the gear beam via the smooth-running bevel gears on the mower drum. The bevel gears and hexagonal shaft run submerged in gear oil. This cuts wear to a minimum and ensures outstanding durability.

Robust construction

The generously proportioned gear beam features a heavy duty cross-section and is designed to cope with the toughest conditions. The mower drums are bolted to the gear beam on the outside so removal is easy.

The precision bearings in the hard-wearing cast bearing housing, which is precision-machined at the CNC machining centre, are designed for the toughest conditions.

Freely rotating glide discs

The glide discs are supplied in two parts and screwed. Replacing them is therefore simple and inexpensive. They have two bearings, which means they can be freely rotated. This not only reduces wear to a minimum but also protects the sward.