Convenience

×

More convenient

Harvesting can mean a long day in the field, so it is all the more important to make your work with the loader wagon as smooth and enjoyable as possible. The practical automatic solutions on the JUMBO go a long way to helping you achieve this.

Automated functions such as loading torque measurement, loading and unloading strategies using the front panel, automatic transport and loading position plus many other functions make things easier whilst supporting you in every scenario.

This ensures you are operating in a relaxed environment whilst getting the most out of your machine.

Next step for hydraulics and electronics concept

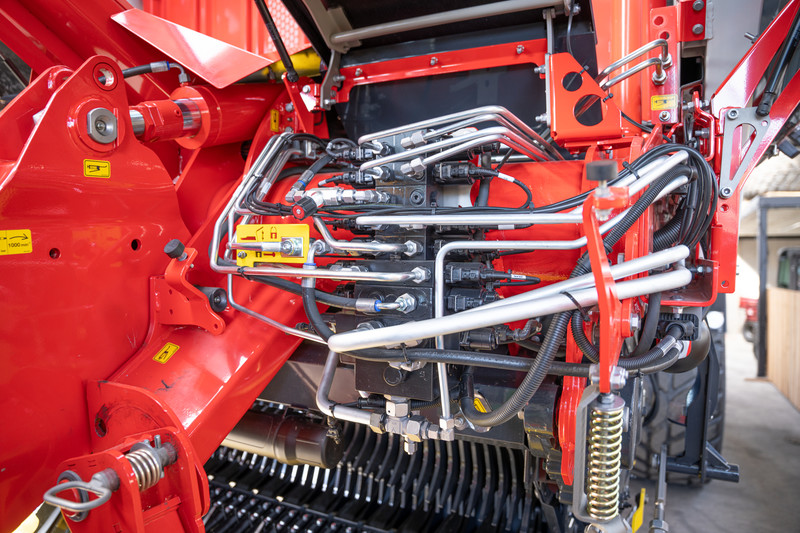

Neatly laid out hydraulics and electronics not only provides a better overview of the whole system, but also makes it more convenient to rectify faults.

During the development of the JUMBO 5000, care was taken to create two separate access points for the hydraulics and electronics in order to make servicing as simple as possible. That is why most of the hydraulic components are located on the left-hand side of the machine and the electronics are on the right-hand side.

Maintenance-friendly

Servicing certain components can take up a great deal of time. That is why the JUMBO 5000 has been designed for easy maintenance. The scraper floor shaft bearings with their central greasing point, the routing of the greasing lines for better accessibility and the service counter help to simplify maintenance.

The service life of specific wear points has been extended considerably, such as the pick-up tines, the loading rotor, the knife steel quality, the chopping unit rear wall and the scraper floor.

In addition, attention has been paid to the durability of the components in both the hydraulic and electronic circuits.

Steered axles

From hydraulic to no-contact and electronic steered axles, an optimum turning angle is guaranteed. The electronic steering enhances convenience when manoeuvring at close quarters, with no special coupling points required. In addition, the improved turning angle prevents damage to track rods or tractor tyres and provides a basis for driving around tight corners. Convenient operation is a priority.