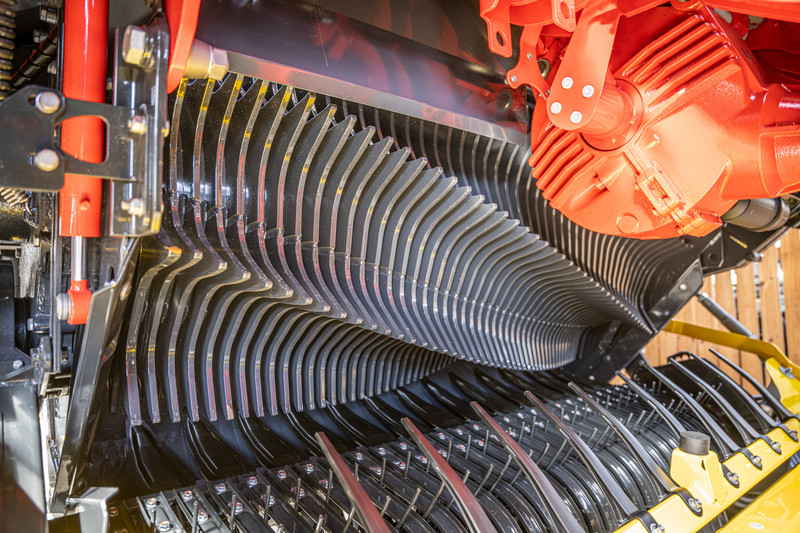

Loading rotor

×

The key component on the JUMBO 5000 is the loading rotor. As the heart of the machine, its robustness and performance are what stand out. The rotor and its gearbox deliver high output chopping and compression.

The rotor is driven by a PTO shaft with a wide-angled joint at both ends and a cam-type clutch to protect the drive train. The large-dimensioned grease filled rotor side drive gearbox is completely maintenance-free.

The bearing is located on the rotor frame between the rotor and gearbox to provide the best protection to the bearing and gearbox. The driveline is protected at an impressive torque of 2500 Nm, corresponding to a peak performance of 360 Hp.

A maximum loading capacity without torque peaks for continuous crop flow is ensured by the loading rotor which has eight rows of tines arranged in a helix. With a width of 1.56 mm, the rotor on the JUMBO 5000 is particularly effective.

The loading rotor has a diameter of 800 mm and, thanks to the helix arrangement of the tines, it can actively feed the forage smoothly through the 34 mm short-chop chopping system. The high intake capacity is predestined for the highest efficiency and performance

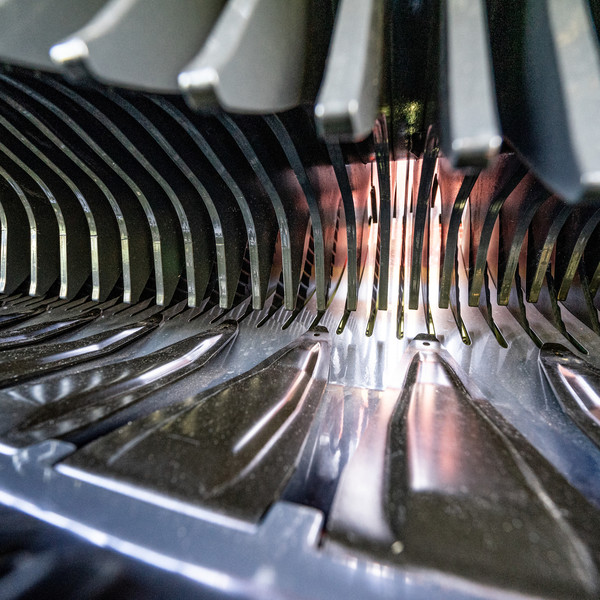

Optimised tine tip

The new tine tip on the 8-row rotor now has more material in the area subjected to the highest load. The best possible compression is achieved by the optimised tine shape in combination with the large scraper surfaces inside the loading chamber. This adds durability and ensures an extended service life.

The wide tips on the rotor tines transfer the crop perfectly from the pick-up, even with wet and short material.

Scrapers

Each of the scrapers in the loading chamber has a wide backing, so the large scraper surface ensures best possible crop retention in the loading chamber. The crop is cleanly scraped off the rotor and is not drawn in.

This allows a high degree of compaction in the loading chamber if need be, which increases the cost effectiveness even when field to farm distances are long.

The scrapers are made of wear-resistant Hardox which gives you the longest possible service life.

Transfer throat

With a width of 1650 mm, the transfer throat ensures high efficiency during the chopping process. The crop is already compressed in the transfer throat to make full use of the loading chamber.

Chopping unit rear wall

The chopping unit rear wall on the JUMBO consists of wear-resistant fine-grained steel. This greatly increases the service life.