Chassis

×

Soil conservation

Always look after the health of your soil. Choose the right tyres, protect the sward, and you will increase your profits.

With the right tyres, there is no contradiction between using high output technology and conserving the soil. In order to protect soil as a natural resource, ensure sustainable soil fertility and maintain soil performance, you need to make sure that loads are uniformly distributed. Using the largest possible dimension of wheels increases the footprint of the tyres so that the soil structure is maintained in the best possible way.

1 cm deep wheel marks cost up to 10 % more diesel. (Source: Lecture by Southwest Falia Agricultural College in Soest, 2008.

Damage to the sward can cause yield losses amounting to 100 €/ha 1).

Heavy compaction can result in fertiliser costs up to 20% higher1).

Parabolic leaf spring chassis 26.5"

The compensator arm on the parabolic leaf spring chassis ensures the load is distributed dynamically especially when braking, this allows the same load to act on each wheel and excellent deceleration values are achieved.

With an axle compensation of 110 mm the chassis has perfect suspension characteristics in the clamp and provides smooth running in the field and on the road. The trailed axles protect the sward even with heavy loads (standard).

A large spring support spacing of 1.1 mm at the front rigid axle with a distance of 856 mm on the rear steered axle provides perfect stability. High strength longitudinal linkages apply the braking and steering force.

Anti roll bar

The anti roll bar gives you 20% greater driving stability, best possible load distribution and better handling on steep ground and when cornering.

A torsion bar on each axle connects the springs on each end to the chassis frame. When loads act on it the bar transfers the pressure automatically to the opposite end.

Optional

Hydraulic steered axles

No-contact steered axles

Intelligent self steering axle driver assist system

EBS - electronic braking system with RSP - roll stability program

Hydro-pneumatic chassis

The hydro-pneumatic chassis gives you a wide support spacing for safe handling, exceptional stability on steep ground as well as enhanced safety when driving at high speeds.

An impressive increase in driving comfort has been achieved by fine-tuning the suspension characteristics. Using a different hydraulic accumulator when the loader wagon is empty from the one when the wagon is full noticeably increases driving comfort.

The chassis with hydro-pneumatic suspension developed by PÖTTINGER absorbs shock loads in the field and on the road. Consequently, it provides markedly greater shock-absorbing comfort than rigid systems that only use tyre suspension. In addition, the tyres are subjected to less wear and the machine follows smoothly in the tractor’s tracks.

The large axle compensation of up to 270 mm ensures better climbing ability on inclines, in the clamp and on poor quality roads.

Standard leaf spring suspension

Wide support of the guide springs with anti roll bar effect – wide support spacings of 1.1 mm and 856 mm

Excellent roll or slope stability due to minimal deflection

Highest level of driving comfort in traffic and off-road

Optimum braking power thanks to equal axle load distribution

The entire vehicle is designed in accordance with the latest provisions of EU type approval.

Weighing system

The JUMBO’s optional weighing system is available for the hydro-pneumatic tandem and tridem chassis. It enables dynamic weighing as a rough guide while driving, and provides exact measurements when parked. (Measuring tolerance +/- 2,5 %)

If the maximum value defined by you is exceeded, a warning is displayed on the control terminal and an acoustic signal is given.

Stable on steep ground

Instead of relying on a complicated and sluggish hydraulically engaged slope compensation, the JUMBO uses mechanics to guarantee an immediate response.

The unique mechanical anti roll bar effect is achieved by integration of longitudinal linkage springs on the chassis, the bolted connection of the axles and the wide spring spacing.

Compensation

The hydro-pneumatic axle compensation ensures uniform wheel pressure in all operating situations. In particular, less pulling power is needed when driving away from a silo plant.

It is also the best way of maximising the loader wagon’s climbing ability.

Suspension

Especially when loading up to 20 ton of crop and driving at up to 65 km/h, top quality vehicle suspension that functions reliably whatever the load status is crucial. What makes this chassis special is the fine-tuning of suspension characteristics when the wagon is empty or full. The result is supremely smooth running, a comfortable ride and not least greater safety when driving.

Ground clearance

The JUMBO is a hugely versatile multipurpose rotor loader wagon that can be deployed in all conditions including difficult terrain. When developing the brake system particular attention was paid to greatest possible ground clearance.

All essential brake components are located above the axle centreline. This ensures that they are well protected and will work reliably.

Tandem chassis

With the hydro-pneumatic tandem chassis, an axle load of 20 ton and overall weight of 24 ton are possible. To reduce rolling resistance still further, 30.5" diameter tyres can be fitted as an option. Compared to 26.5” ground pressure is marginally reduced.

A self steering axle protects the sward even with heavy loads (standard).

The outstanding feature of this chassis is its tremendous manoeuvrability in the field.

Tridem chassis

The hydro-pneumatic tridem chassis distributes heavy axle loads of 27 ton over a large surface area. Thanks to the fine tuning of the suspension characteristics, maximum driving comfort is ensured when empty and when full. In addition, the anti roll bar provides stability on steep and bumpy ground due to the minimal deflection of the large support spacing.

Electronic steered axles on the tridem

EZL steering programmes for tridem axle:

Normal steering

This programme is not always automatically activated. The steering angle is regulated according to speed.

Crab steering

Sets the same steering angle for all steered axles.

Offset

This special steering programme is used for anti roll compensation when driving on the slant.

Lift axle tridem

Minimises wear to the tyres when the wagon is empty.

In difficult terrain a lift axle can be deployed to temporarily increase the drawbar load and the tractor’s traction.

A safety pressure valve automatically lowers the lift axle in the event of an overload to protect the tractor.

The system is operated conveniently from the control terminal in the tractor cab.

Self steering axle

With its standard self steering axle, the JUMBO is particularly manoeuvrable and conserves the soil. The tight turning angle means that the sward is not damaged even on the tightest corners. On steep ground and in the clamp, the axle can be locked using the control terminal.

If the tractor is equipped with ISOBUS and can output the driving direction and speed, then the axle can be locked automatically according to these parameters.

Intelligent self steering axle

With the intelligent self steering axle, the loader wagon autonomously detects the movement. It allows automatic axle locking under all operating conditions even without a speed signal from the tractor.

A direction-of-rotation sensor detects the speed of forward and backward travel and locks the axle within the speed range you have previously defined.

The inclination sensor also locks the axle when the defined inclination is reached. If the defined inclination value is exceeded, you can also have a warning displayed on the control terminal screen.

Hydraulic steered axles

The optional hydraulic steered axles guarantee absolute reliability and excellent tracking whilst conserving the sensitive sward.

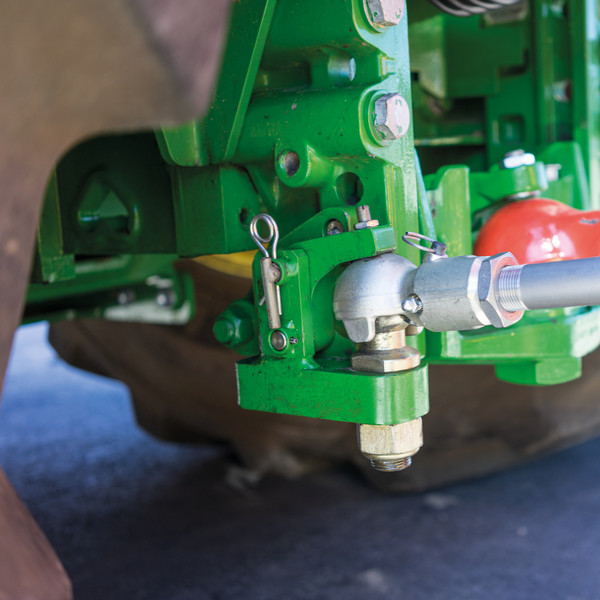

They have a track rod with a K50 ball head coupling. Thanks to the telescoping automatic interlock, the loader wagon can easily be removed by only one person. The coupling point for the steered axles on the tractor according to ISO DIN 26402 is based on the K80 ball and is a backlash free towing device, this option guarantees precise tracking even on steep ground and in the clamp.

No-contact electronic steered axles

The no-contact, electronic steered axles completely eliminate the need for mechanical steering angle sensors between the tractor and the wagon. A high-resolution sensor system controls the steering. By eliminating the track rod next to the drawbar, tighter turning angles are possible. Damage to track rods and tractor tyres is excluded. It is easier to attach the loader wagon because no special devices are required for coupling the track rod to the tractor. This avoids the extra maintenance and adjustment work needed with conventional forced steering systems.