Technology for your plough

×Technology for your plough

The beam link - a central component

The beam link - a central component

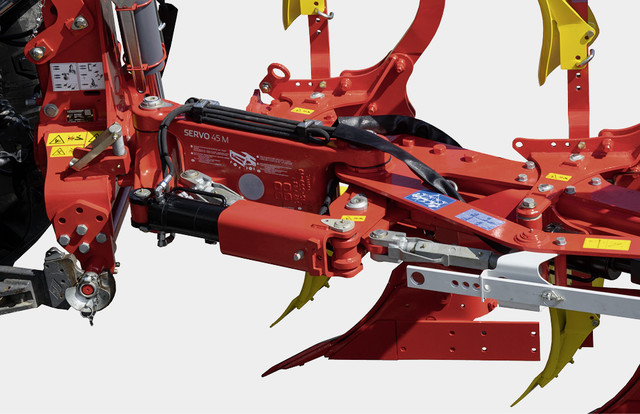

The conical shape of the beam link with wide spaced mounting on the reversing unit means it can absorb high load torques. The pins in the lubricated pivot points are equipped with anti twist locks this prevents excessive wear. Replaceable bushes in the reversing unit and bearing block pivot points guarantee a long service life.

Beam pivot system available on standard ploughs

Beam pivot system available on standard ploughs

With wide furrows, long inter-body spacing and when lifting clearance is too low, the plough beam is hydraulically pivoted while reversing. The plough is narrow for road transport and parking. The hydraulic cylinder has a check valve so that the hoses are not under pressure during ploughing.

Ploughing with a furrow press

Ploughing with a furrow press

The press is collected by the press arm's large jaw. It is hydraulically released before the plough is turned over.

A five-position mounting means the furrow press can be set for different working widths. A tension spring pivots the press arm into the set catching position after releasing.

On SERVO PLUS ploughs, the catching position is maintained precisely even if the furrow width is changed.

The press arm can be fixed within the tractor width for road transport.

The entire press arm can be removed quickly and easily.