Unloading at the press of a button

×Unloading at the press of a button

Automatic unloading

Unloading

A press of a button on the control terminal is all that is needed and the full cross section of the tailgate opens to unload TORRO L models in a few minutes. The automatic unloading system makes life easier for the driver and protects the machine.

Metering on demand

Uniformly distributed blanket of forage

TORRO D Models

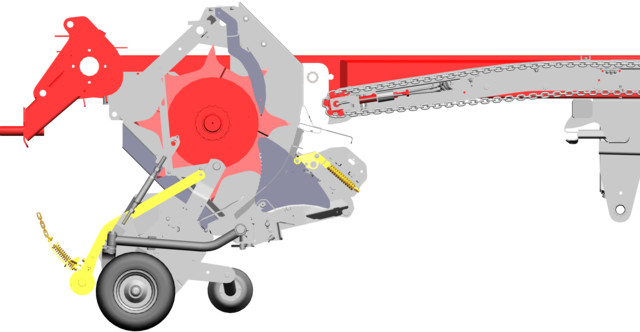

A uniformly distributed blanket of forage is essential for perfect compaction. Two beater rotors guarantee perfect distribution. The aggressive tines deliver an impressive performance even with highly compressed forage. Bars on the rotors ensure maize material can be unloaded effectively. A pressure sensor in the beater rotor bearings controls the scraper floor automatically.

Multifunction tailgate

The tailgate opening angle can be set to different positions from the tractor seat to minimise the effects of crosswinds.

New: Beater driveline protected to 1700 Nm.

Automatic chain tensioner.

Easily access central greasing point.

Third beater rotor available as an option.

Fine metering optional (only with roof ropes and rear tarpaulin)

Cross conveyor belt

Cross conveyor belt

The optional cross conveyor belt is 890 mm wide and is powered hydraulically.

Runs to left and right.

Tailgate locking system.

Remote control using optional POWER CONTROL Wireless.

Lowered scraper floor

Lowered scraper floor

The scraper floor has been lowered by 150 mm at the front end. The forage is conveyed upwards to the rear for uniform and smooth discharge. Hassle-free unloading with a low power requirement and four powerful drive chains ensure rapid unloading.

A two-speed motor is standard for unloading speed of up to 18 metres per minute.

The scraper floor transmission is located on the centreline of the wagon.

Durable wooden floor

Longevity of scraper floor

The PÖTTINGER scraper floor guarantees long term reliability. The load chamber floor is constructed of pressure treated, durable wood. The tongue and groove boards are bolted to the frame. The hardened bars are offset and easily accessible and the the greasing points for the scraper floor shafts are located at the side of the wagon.

View from underneath

Load sensing

All PÖTTINGER silage wagons are load-sensing compatible. The required oil flow rate is precisely measured and adjusted to demand. This prevents the oil from heating up and saves power by up to 20 hp (15 kW).