PCS – PRECISION COMBI SEEDING

×

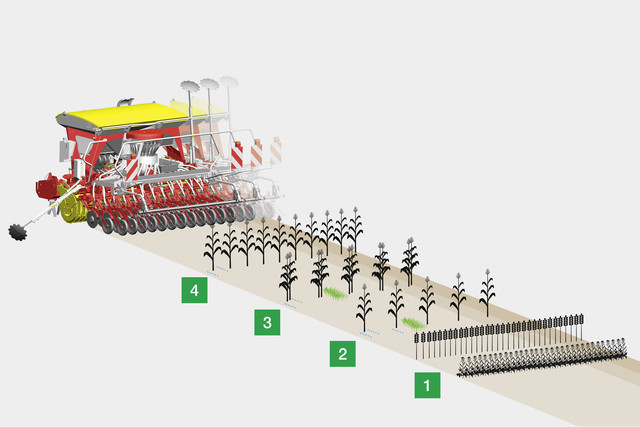

1 AEROSEM A / AEROSEM ADD

Wheat, barley, oats, rye spelt, sunflower seeds, beans, peas oil seed rape, poppy seeds, phacelia, mustard

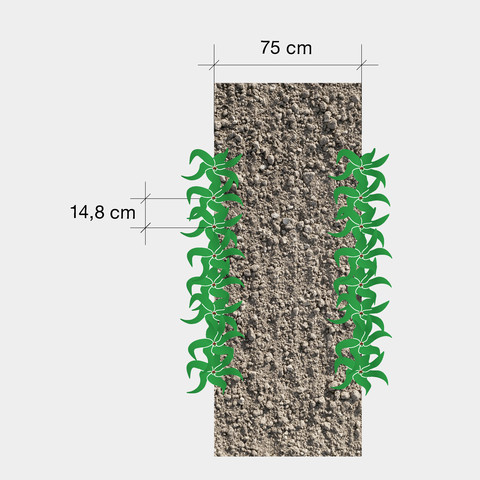

2 AEROSEM PCS

Maize, row spacing 75 cm optional simultaneous fertiliser application of 1 or 2 bands or simultaneous application of companion crop seed between the maize

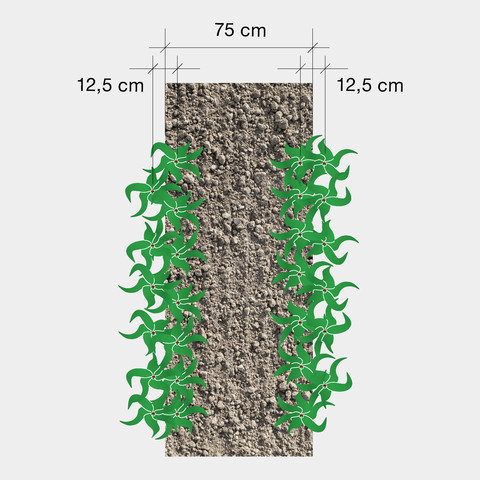

3 AEROSEM PCS DUPLEX SEED

Maize, row spacing 75 cm / 12.5 cm optional fertiliser application with a band next to each row or simultaneous application of companion crop seed between the maize

4 AEROSEM PC

Maize, row spacing 37.5 cm optional fertiliser application with a band next to each row

All-in-one for pure flexibility

The PCS (Precision Combi Seeding) option integrates precision seed drill technology into a rigid pneumatic seed drill, this allows you to operate independently of dedicated precision seed drill. This means greater flexibility and a more cost effective operation when using your AEROSEM ADD seed drill.

Precision maize drilling

One seed drill for multiple tasks:

Cereals

Maize / maize with fertiliser / maize with companion crop

Fertiliser applied directly to the maize row

Exact seed separation

The single-seed precision metering elements are located beneath the seed hopper. This hydraulically-driven system ensures exact mechanical separation of the seed. The air stream transports the seed to the coulters, during this time an optical sensor monitors the distribution of the seed in the row. This monitoring system allows for:

Easy adjustment of seeds per m22

Precise monitoring of seed distribution in the seed slot

Pneumatic seed transport

An air flap divides the air stream between the standard metering system and the PCS. Under pressure, the air system injector takes the individual seeds from the seed elevator and transports them at precise intervals to the coulter.

A seed flow sensor monitors reliable seed transport and indicates to the driver the accuracy of seed distribution in the seed slot.

Perfectly placed

The DUAL DISC coulter with its integrated seed slot former ensures a perfect seed slot. A stopper roller presses the seed into the furrow. A press wheel controls consolidation and working depth. The seed placement depth can be adjusted centrally.

No vertical drop

Exact seed placement

Seed does not roll along slot

Optimum covering of seed

Uniform seed germination

DUPLEX SEED – sowing maize in double rows

With 12.5 cm spacing in the double row, and 75 cm spacing between the double rows

The double spacing in the row ensures a better plant distribution density of the maize plants

Increase in yield of up to 5.5 % possible with silage maize and corn maize

Maize sown at 37.5 cm

Optimum plant distribution density of all maize plants thanks to shorter spacing in the seed slot

Optional tramline switching means that crop care access is no problem even with small row spacing

AEROSEM | 3002 A / ADD | 3502 A / ADD | 4002 A / ADD |

Working width | 3.0 m | 3.5 m | 4.0 m |

Number of rows | 24 / 20 | 28 | 32 / 26 |

Row spacing | 12.5 / 15 cm | 12.5 cm | 12.5 / 15 cm |

AEROSEM PCS | 3002 ADD | 3502 ADD | 4002 ADD |

Working width | 3.0 m | 3.5 m | 4.0 m |

Number of cereals rows 12.5 cm | 24 | 28 | 32 |

Number of maize rows 75 cm | 4 | 5 | 5 |

Number of maize rows DUPLEX SEED | 8 | 10 | 10 |

Number of maize rows 37.5 cm | 8 | 9 | 10 |