TERRADISC 8001 T / 10001 T

×TERRADISC 8001 T / 10001 T

TERRADISC 10001 T

1st Depth adjusted hydraulically using rear rollers

2nd Solid, forged TWIN ARM disc mounting system

3rd Large jockey wheels for perfect ground tracking

4. Choice of rear rollers for optimum consolidation

Reliability and flexibility

Reliable penetration even in dry conditions.

Harvest residues are incorporated blockage-free.

Perfect seedbed preparation.

Working depth variable between 5 cm and 15 cm.

Efficiency

The PÖTTINGER TERRADISC models offer their full working width in the field.

Wear part replacement costs are kept low because these strong discs have a diameter of 580 mm and a material thickness of 5 mm.

High output thanks to high driving speeds.

Convenience

Multiple adjustment capabilities.

Low maintenance requirement – discs mounted on sealed bearings.

Convenient operation – ISOBUS functionality thanks to our EXPERT control terminal.

Carriage chassis ensures smooth running and compact transport dimensions.

A pressure correction factor for the folding sections and the rear roller can be set on both the standard control terminal versions and the ISOBUS systems.

The inclination adjustment to control crabbing is operated using the central cylinder and is also standard on both machines. Efficient operation without overlaps is guaranteed as a result.

Working results

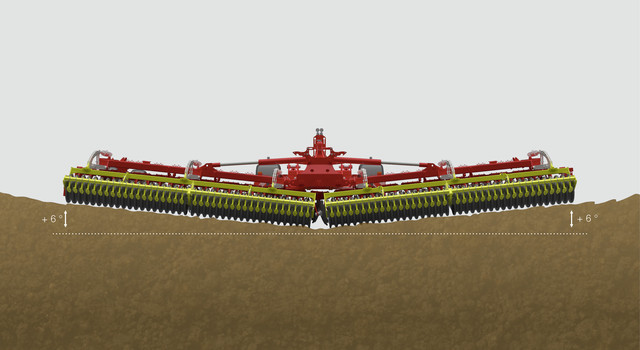

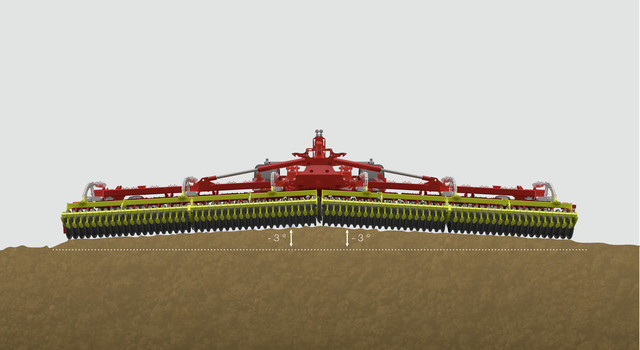

Ground tracking up

Ground tracking down

Perfect ground tracking with +6° / -3° freedom of movement

Uniform working depth.

Reliable incorporation of high volumes of organic matter thanks to TWIN ARM system.

The best soil movement.

Optimum consolidation.

Ideal utilisation of the tractor's pulling power – saves fuel.

Perfect working results

Perfect penetration and no sideways deviation is guaranteed, even on dry soil. The TERRADISC guarantees neat incorporation of harvest residues, especially with high levels of straw and mulch residues.

This is ensured by the aggressive disc angle as well as the offset arrangement of the proven TWIN ARM system. The high tare weight of the TERRADISC also ensures the dependable performance of this disc harrow. Hydraulic jockey wheels (dual depth wheel 340/55-10) are available as an option for perfect ground tracking.

Smooth operation

The dedicated chassis ensures confident handling during road transport and in operation. Hydraulic accumulators delivers smooth operation and promote reliable penetration in all soil conditions. In addition to the hydraulic accumulators, the jockey wheels guarantee a smooth ride. These are standard on the TERRADISC 10001 T.

Pure soil conservation

You can choose from the following rear rollers: Cage roller, pack ring roller, tandem CONOROLL and rubber packer roller.

At the headland the TERRADISC T is raised onto the rear roller and its weight distributed across the whole working width.

The trailed TERRADISC is therefore very light on its feet at headlands.

Guaranteed reliability

Ideal cultivating results are achieved thanks to optimum spacing of the discs.

There is plenty of space between the discs and the carrier arms with the TWIN ARM system. Guaranteed blockage-free, even with heavy harvest residues.

The working depth is adjustable between 5 cm and 15 cm. This is set by adjusting the jockey wheels and the rear rollers.

The frame sections are pre-tensioned hydraulically to ensure uniform ground pressure regardless of the working position. This allows the flexible frame sections to follow the ground contours with a constant working depth.

A front board is available as an option to level the soil in front of the discs. This produces a better result in ploughed fields.

High output

The TERRADISC 8001 T and the TERRADISC 10001 T deliver an impressive output thanks to high working speeds. This is enabled by the disc harrow's strong design and large wheels.